Installing carbon fiber wheel tubs is one of the most effective upgrades for drag racing and high-performance vehicles, providing superior strength-to-weight ratio while accommodating larger tire sizes. This comprehensive guide breaks down the installation process into four manageable steps, ensuring you achieve professional results while maintaining safety and precision throughout the project.

Introduction to Carbon Fiber Wheel Tubs

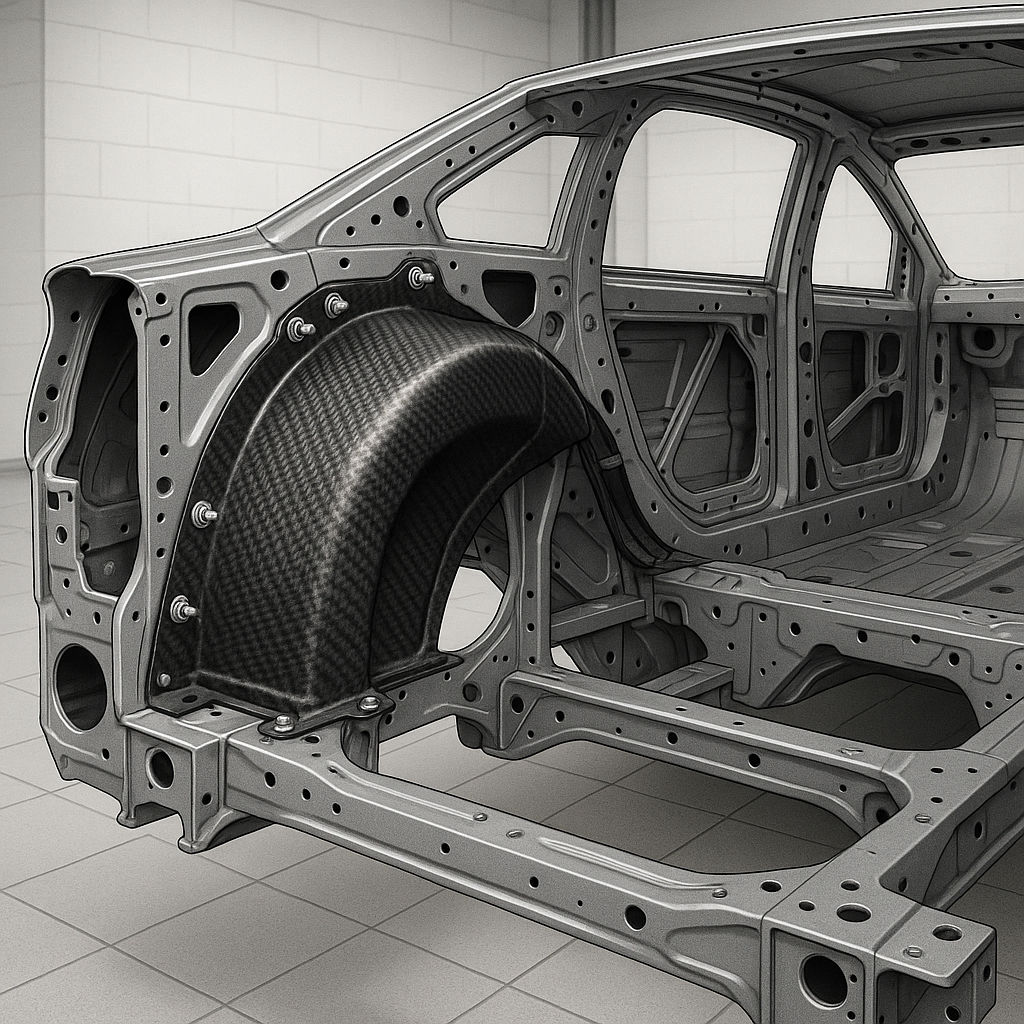

Carbon fiber wheel tubs represent the pinnacle of lightweight performance engineering in drag racing and high-performance automotive applications. These advanced composite components replace traditional steel or aluminum wheel wells, offering exceptional strength while dramatically reducing weight. The technology behind carbon fiber wheel tubs stems from aerospace and Formula 1 racing, where every gram matters for performance optimization.

Modern carbon fiber wheel tubs are constructed using multiple layers of 3K 2x2 twill weave carbon fiber, creating a laminated structure that provides superior impact resistance and dimensional stability. The manufacturing process involves hand-laying carbon cloth with fire-retardant resin, followed by vacuum-bag curing to eliminate air bubbles and ensure consistent thickness throughout the component. Most high-quality tubs feature a Coremat liner on the interior surface, which protects the show-quality exterior finish from debris and provides additional structural reinforcement.

The installation of carbon fiber wheel tubs is not merely a cosmetic upgrade but a fundamental chassis modification that affects vehicle dynamics, weight distribution, and tire clearance capabilities. These components are specifically designed to accommodate larger rear slicks commonly used in drag racing applications, with popular sizes including 47-inch diameter tubs that can house massive racing slicks for maximum traction. The aerodynamic benefits of properly installed wheel tubs also contribute to improved high-speed stability and reduced drag coefficients.

Understanding the technical specifications is crucial before beginning any installation project. Carbon fiber wheel tubs typically weigh approximately 11 pounds for a complete pair, compared to traditional aluminum tubs that can weigh significantly more. This weight reduction directly translates to improved acceleration, reduced unsprung weight, and better overall vehicle performance. Additionally, carbon fiber's resistance to fatigue ensures longevity even under the extreme stresses of competitive drag racing environments.

Benefits and Performance Advantages

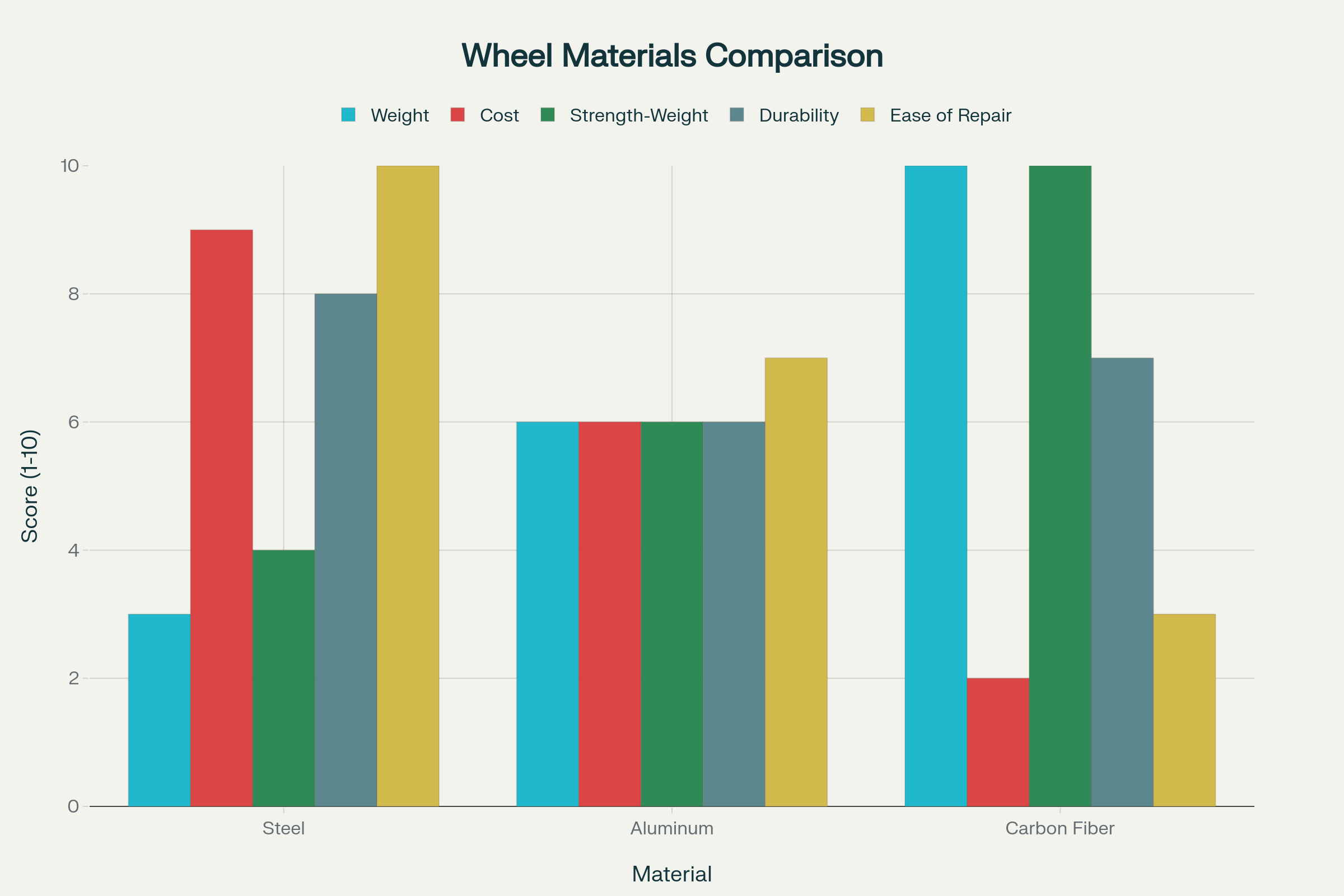

The performance advantages of carbon fiber wheel tubs extend far beyond simple weight reduction, encompassing multiple aspects of vehicle dynamics and operational efficiency. The primary benefit lies in the exceptional strength-to-weight ratio that carbon fiber provides compared to traditional materials like steel or aluminum. This characteristic allows for the construction of larger wheel wells without the corresponding weight penalty, enabling the use of wider tires for improved traction and performance.

Carbon fiber's inherent properties make it ideal for high-stress applications where traditional materials might fail. The material exhibits excellent fatigue resistance, meaning it maintains structural integrity even after thousands of high-stress launches and hard landings. Unlike aluminum, which can crack or develop stress fractures over time, carbon fiber wheel tubs maintain their original strength characteristics throughout their service life. This durability translates to lower long-term maintenance costs and improved safety margins during competition.

The aerodynamic benefits of carbon fiber wheel tubs cannot be overlooked in high-performance applications. The smooth, contoured surfaces created by the molding process eliminate sharp edges and discontinuities that can create turbulence and drag. Professional chassis builders often integrate wheel tubs seamlessly with the vehicle's overall aerodynamic package, creating smooth airflow transitions that reduce drag and improve high-speed stability. This attention to aerodynamic detail becomes increasingly important as vehicle speeds increase.

Installation flexibility represents another significant advantage of carbon fiber wheel tubs. The material's workability allows for precise customization during the fitting process. Unlike rigid aluminum or steel alternatives, carbon fiber can be trimmed and shaped with standard tools while maintaining structural integrity. This flexibility enables custom installations that perfectly match individual chassis requirements and tire clearance needs.

The thermal properties of carbon fiber also provide operational advantages in racing environments. Carbon fiber exhibits low thermal conductivity, helping to isolate the passenger compartment from heat generated by the differential and exhaust components. This thermal barrier effect improves driver comfort during long racing sessions and helps maintain consistent interior temperatures. Additionally, carbon fiber's resistance to thermal expansion ensures dimensional stability across varying temperature ranges commonly encountered in racing applications.

Pre-Installation Planning and Safety

Proper planning forms the foundation of any successful carbon fiber wheel tub installation, requiring careful consideration of vehicle specifications, racing requirements, and safety protocols. The planning phase should begin with a thorough assessment of the vehicle's current configuration, including rear axle setup, suspension geometry, and intended tire sizes. This initial evaluation determines the specific wheel tub dimensions required and identifies any potential clearance issues that must be addressed during installation.

Safety considerations must be prioritized throughout the planning process, particularly when working with carbon fiber materials and performing chassis modifications. Carbon fiber dust generated during cutting operations can pose respiratory hazards, requiring proper ventilation and personal protective equipment. The microscopic carbon fibers can become airborne during cutting operations and should never be inhaled. Professional-grade dust masks or respirators rated for fine particulates are mandatory when performing any cutting or grinding operations on carbon fiber components.

Vehicle preparation involves more than simply accessing the wheel well areas. The fuel system must be completely drained and made safe before beginning any cutting operations near the rear of the vehicle. All electrical systems in the work area should be disconnected to prevent accidental ignition of flammable vapors. Interior components, including seats, carpeting, and trim panels, should be removed or adequately protected from welding sparks and debris generated during the installation process.

Regulatory compliance represents a critical planning consideration for vehicles intended for organized racing competition. Both NHRA and IHRA have specific requirements for wheel tub installations in various racing classes. These regulations may specify minimum ground clearance, maximum wheel well openings, and required safety features such as debris shields or fire suppression system compatibility. Understanding these requirements before beginning work prevents costly modifications or disqualifications during technical inspection.

The planning phase should also include consideration of the installation timeline and workspace requirements. A typical carbon fiber wheel tub installation requires 13-20 total hours of work, spread across multiple days to allow for proper curing of adhesives and sealants.

The workspace must provide adequate lighting, ventilation, and access to both the interior and exterior of the vehicle. Professional installation bays often feature overhead hoists and specialized fixtures to support the vehicle during the modification process.

Tools and Materials Required

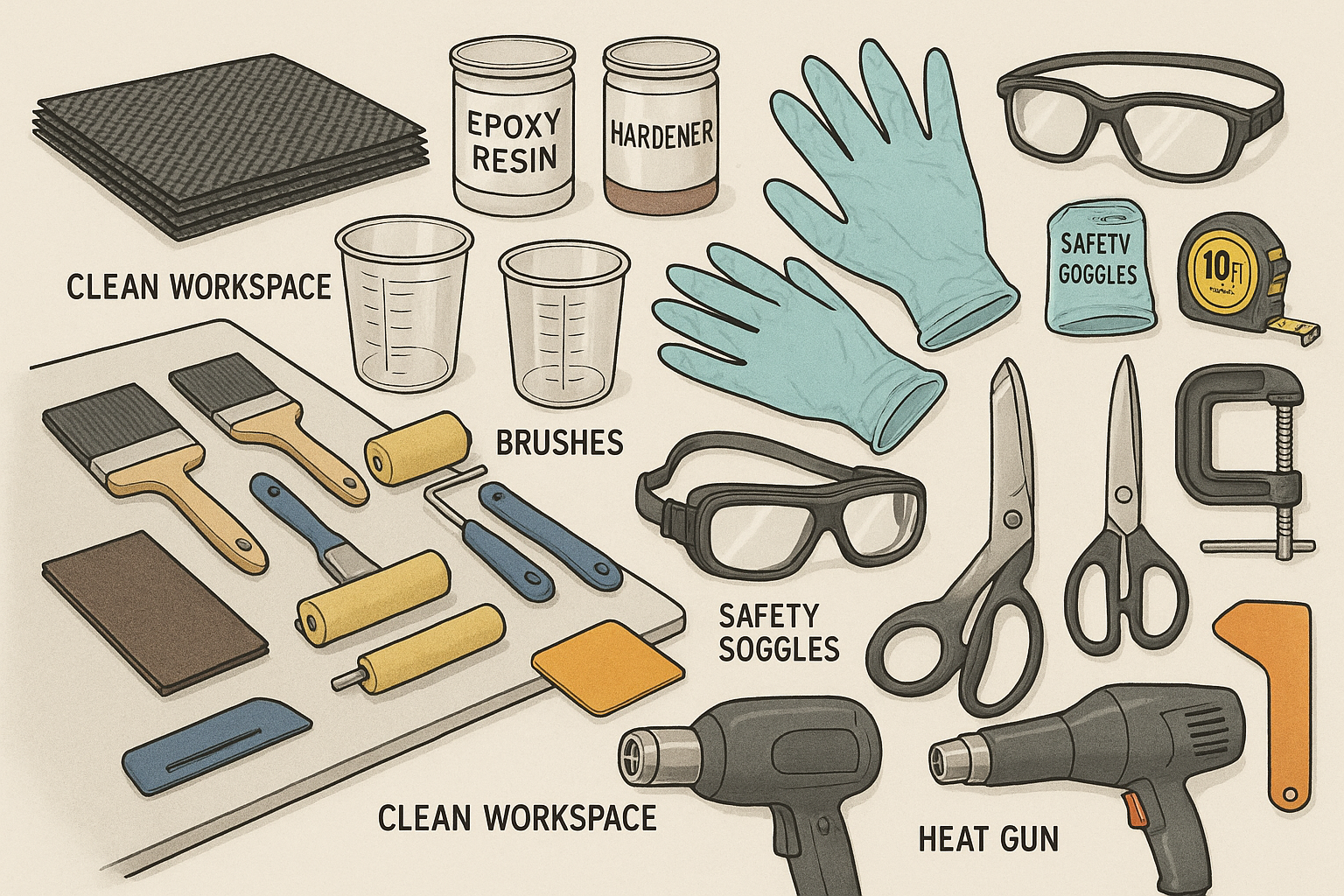

The successful installation of carbon fiber wheel tubs demands a comprehensive collection of specialized tools and materials, each serving specific functions in the modification process. Professional-quality equipment not only ensures superior results but also enhances safety during potentially hazardous operations such as cutting and fitting. The investment in proper tools typically pays dividends through improved work quality and reduced installation time.

Cutting equipment forms the cornerstone of any wheel tub installation toolkit. A high-quality cut-off wheel or angle grinder with multiple disc types enables precise cuts in both the existing wheel wells and frame rail modifications. Diamond-coated cutting wheels specifically designed for composite materials provide the cleanest cuts in carbon fiber while minimizing delamination and edge fraying. For precision work, a tile saw with a diamond blade offers superior control and finish quality when trimming carbon fiber components to final dimensions.

Measuring and marking tools ensure accuracy throughout the installation process. Professional-grade measuring tapes, squares, and levels prevent costly errors that could compromise fit and finish. Cardboard sheets for template creation are essential, as they allow for multiple test fittings before committing to final cuts on expensive carbon fiber components. Silver or white marking pens show clearly on carbon fiber surfaces and resist smearing during handling.

Fastening and mounting hardware must meet the demanding requirements of high-performance racing applications. Stainless steel button-head screws, aircraft-quality rivets, and temporary clecos enable secure attachment while maintaining the professional appearance expected in carbon fiber installations. Panel bonding adhesive specifically formulated for carbon fiber applications provides additional strength and sealing capabilities beyond mechanical fasteners alone.

Safety equipment cannot be considered optional when working with carbon fiber materials and power tools. NIOSH-approved respirators protect against carbon fiber dust inhalation, while impact-resistant safety glasses shield eyes from flying debris during cutting operations. Heat-resistant gloves protect hands while maintaining dexterity required for precise work. Fire extinguishers rated for electrical and chemical fires should be immediately accessible throughout the installation process.

Step 1: Planning and Preparation

The initial phase of carbon fiber wheel tub installation establishes the groundwork for a successful project through meticulous planning and comprehensive vehicle preparation. This stage typically requires 2-4 hours but can significantly impact the quality and efficiency of subsequent installation steps. Professional installers emphasize that time invested in proper preparation invariably reduces complications and rework during later phases of the project.

Vehicle positioning and support represent the first critical considerations in the preparation phase. The car must be elevated sufficiently to provide comfortable access to both the interior and underside simultaneously. Professional shops typically use four-post lifts or comprehensive jack stands that allow the vehicle to remain stable while providing unrestricted access to all work areas. The vehicle should be positioned level to ensure accurate measurements and proper alignment during the installation process.

Complete fuel system safety procedures must be implemented before beginning any work near the rear of the vehicle. This includes draining the fuel tank, removing or disconnecting fuel lines, and ensuring adequate ventilation to prevent vapor accumulation. Many professional installers require a 24-hour waiting period after fuel system drainage before beginning cutting operations. Fire suppression equipment should be positioned strategically around the work area and all personnel should understand its operation.

Interior component removal extends beyond simple access considerations to include protection of valuable trim and upholstery pieces. Rear seats, interior panels, carpet sections, and any electronic components in the work area should be carefully removed and stored in protected locations. This systematic approach prevents damage from welding sparks, cutting debris, or adhesive overspray. Professional installations often include complete interior masking with fire-resistant materials to protect areas that cannot be practically removed.

The preparation phase concludes with a comprehensive measurement and documentation process. Existing wheel well dimensions, tire clearances, and chassis reference points should be recorded photographically and dimensionally. This documentation serves as a baseline for comparison during the installation process and provides reference points for troubleshooting if complications arise. Many professional installers create detailed measurement sheets that accompany each vehicle throughout the installation process.

Tool preparation and organization ensure efficient workflow during subsequent installation phases. All cutting tools should be inspected for proper operation and equipped with appropriate blades or discs for the materials involved. Measuring instruments should be calibrated and readily accessible. Template materials should be organized and pre-cut to approximate sizes to minimize interruptions during the fitting process.

Step 2: Removal and Frame Modification

The removal and frame modification phase represents the most technically demanding aspect of carbon fiber wheel tub installation, requiring 4-6 hours of precise work and potentially irreversible chassis modifications. This stage involves removing existing wheel tubs, modifying frame rails for clearance, and preparing mounting surfaces for the new carbon fiber components. The irreversible nature of these modifications emphasizes the importance of careful planning and precise execution.

Existing wheel tub removal begins with systematic disconnection of all attachment points between the original tubs and the vehicle chassis. Factory wheel tubs are typically attached through a combination of spot welds, mechanical fasteners, and structural adhesives. Professional removal techniques involve careful drilling of spot welds to preserve maximum structural material while completely separating the old components. Plasma cutting or torch work may be necessary for heavily corroded or painted connections, requiring appropriate fire safety precautions.

Frame rail modification often represents the most challenging aspect of the entire installation process. Many vehicles require strategic notching or reshaping of rear frame rails to accommodate wider tire clearances. These modifications must maintain structural integrity while providing adequate clearance for the intended tire sizes. Professional installations typically involve creating new mounting surfaces from steel plate or tubing, welded into place with full penetration welds that meet or exceed original equipment strength specifications.

The modification process requires careful attention to suspension geometry and load paths. Removing material from frame rails can affect the vehicle's structural dynamics and crash safety characteristics. Experienced installers often reinforce modified areas with additional steel plating or tubing to maintain original strength levels. These reinforcements must be designed to distribute loads appropriately while maintaining clearance for suspension components and drivetrain elements.

Template creation begins during the removal phase as original wheel tub shapes and mounting points are documented. Cardboard templates made from the removed components provide excellent starting points for fitting the new carbon fiber tubs. These templates can be modified and refined throughout the fitting process without risking damage to expensive carbon fiber components. Professional installers often create multiple template iterations to perfect the fit before making final cuts on the wheel tubs.

Surface preparation for mounting the new tubs requires meticulous attention to cleanliness and adhesion properties. All mounting surfaces must be cleaned of paint, rust, oils, and other contaminants that could compromise the bond between carbon fiber and chassis components. Steel surfaces often require light sandblasting or grinding to create proper mechanical adhesion surfaces. The use of appropriate primers or bonding agents may be specified by the wheel tub manufacturer to ensure optimal adhesion strength.

Quality control during the modification phase involves frequent measurement checks and test fitting procedures. Professional installers typically perform multiple test fittings with cardboard templates throughout the modification process to ensure proper clearances are maintained. This iterative approach prevents over-cutting or under-cutting situations that could compromise the final installation quality or require expensive remedial work.

Step 3: Template Creation and Fitting

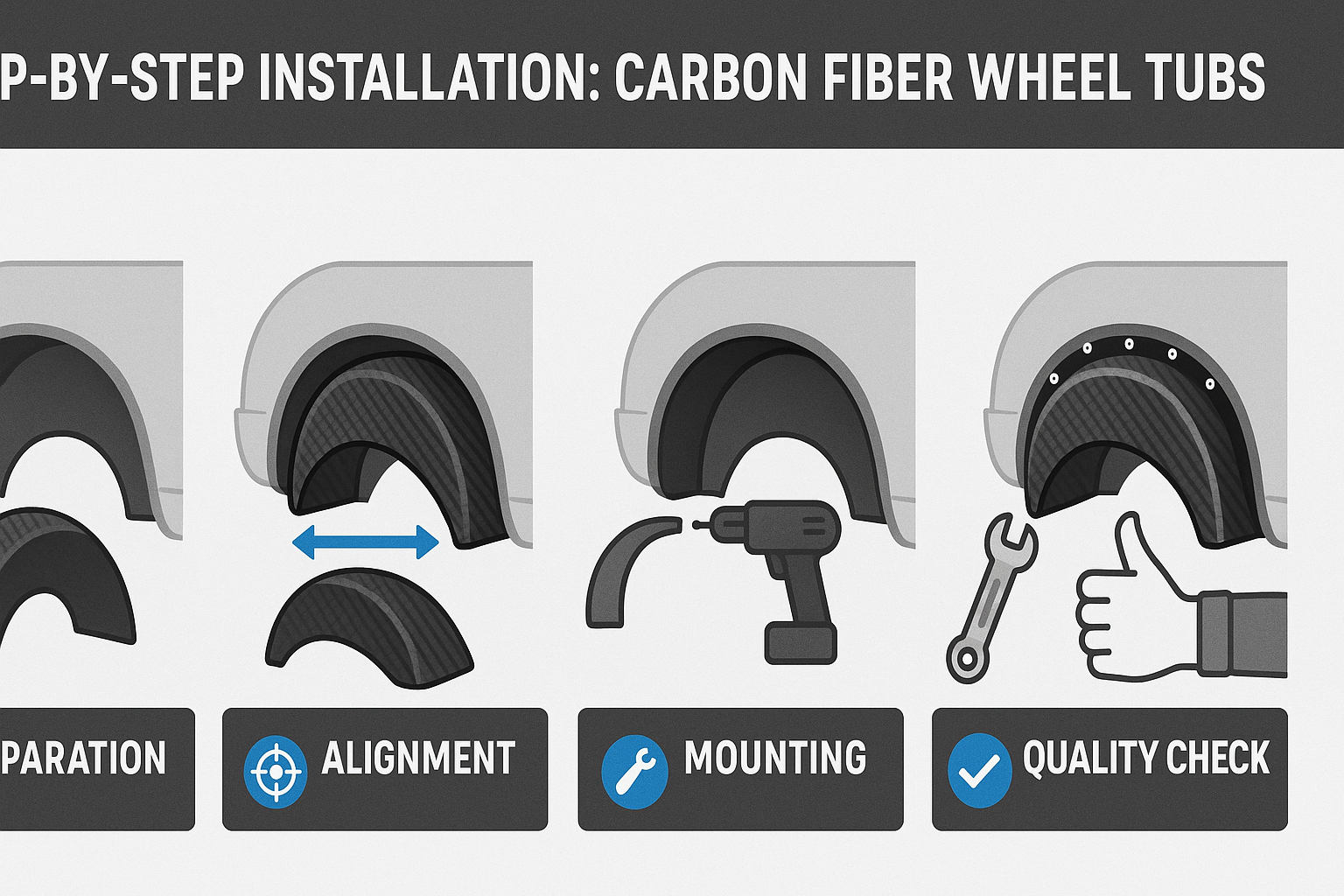

Template creation and fitting represents the bridge between chassis modification and final installation, requiring 3-4 hours of meticulous work to ensure perfect fitment of expensive carbon fiber components. This phase demands exceptional attention to detail, as errors in template creation can result in costly mistakes during final cutting and fitting operations. Professional installers consider this phase critical to achieving showroom-quality results that meet both functional and aesthetic requirements.

The cardboard templating process begins with creating accurate three-dimensional representations of the required wheel tub shapes. High-quality corrugated cardboard provides sufficient structural integrity for multiple test fittings while remaining easy to cut and modify. The template creation process typically starts with oversized cardboard pieces that are gradually trimmed to achieve perfect fit. This approach prevents the common mistake of cutting templates too small initially, which cannot be easily corrected.

Professional template creation techniques involve systematic measurement and marking procedures that ensure consistent results. The wheel tub centerline must be precisely located relative to the axle centerline, typically requiring measurements from multiple reference points on the chassis. Many installers mark cardboard templates every three inches around the radius to facilitate accurate transfer of measurements to the actual carbon fiber components. These marks serve as reference points for both cutting and mounting operations.

Three-dimensional fitting requires careful attention to compound curves and clearance requirements throughout the wheel well opening. The template must accurately represent not only the basic tub shape but also the transition areas where the tub interfaces with existing body panels and frame components. Professional installers often use flexible measuring devices or contour gauges to capture complex curves that cannot be easily measured with conventional rulers or squares.

Multiple test fitting iterations allow for gradual refinement of template accuracy. Each test fitting should include checks for tire clearance, suspension travel clearance, and interference with chassis components. The template should be positioned using temporary clecos or clamps to simulate final mounting conditions during these test fittings. Any interference issues discovered during template testing can be resolved through template modification rather than expensive rework of carbon fiber components.

Clearance verification extends beyond static measurements to include dynamic considerations such as suspension compression and tire growth at high speeds. Professional installations typically include calculations for tire diameter increase due to centrifugal force and thermal expansion during high-speed operation. These considerations ensure adequate clearance margins that prevent tire contact with wheel tubs during actual racing conditions.

Transfer techniques for moving template measurements to carbon fiber components require precision and care to prevent errors. Many professional installers use the cardboard template as a cutting guide, tracing around its perimeter with appropriate marking tools. Alternative techniques involve creating paper patterns from the cardboard templates, which can be temporarily adhered to carbon fiber surfaces with spray adhesive. This approach prevents marking directly on expensive carbon fiber components while maintaining accuracy.

Quality assurance during the template phase involves verification measurements taken from multiple reference points on the chassis. These measurements should be recorded and compared with template dimensions to ensure consistency and accuracy. Professional installers often photograph template positioning from multiple angles to document proper fitment before proceeding to final cutting operations. This documentation proves valuable if questions arise during subsequent installation phases.

Step 4: Final Installation and Mounting

The final installation and mounting phase culminates the wheel tub installation project, requiring 4-6 hours of precise work to achieve professional-quality results. This critical stage involves cutting the carbon fiber tubs to final dimensions, creating secure mounting attachments, and sealing all interfaces to prevent water infiltration and ensure long-term durability. The irreversible nature of cutting operations on expensive carbon fiber components demands exceptional care and attention to detail throughout this phase.

Carbon fiber cutting techniques require specialized approaches to prevent delamination and achieve clean, professional-quality edges. The preferred cutting method involves using a fine-toothed hacksaw or diamond-coated cutting wheel designed specifically for composite materials. Professional installers typically score the cutting line completely around the tub's circumference before making the final cut, which helps prevent fiber pullout and edge fraying. Masking tape applied along the cutting line provides additional protection against surface damage during cutting operations.

Precision trimming operations should proceed gradually, removing small amounts of material with frequent test fittings to ensure optimal fit. The carbon fiber material's flexibility allows for minor adjustments during installation, but excessive removal cannot be corrected. Professional practice involves leaving approximately 1/16 inch of extra material initially, then fine-tuning the fit through careful sanding with progressively finer grits. This approach ensures perfect fitment while maintaining structural integrity along cut edges.

Mounting attachment methods for carbon fiber wheel tubs typically combine mechanical fasteners with structural adhesives to achieve optimal strength and sealing. Stainless steel button-head screws provide reliable mechanical attachment while maintaining the professional appearance expected in high-end installations. Panel bonding adhesive specifically formulated for carbon fiber applications creates a secondary bond line that distributes loads and seals against water infiltration.

The mounting process requires careful attention to load distribution and stress concentration prevention. Carbon fiber's directional strength characteristics mean that mounting holes should be positioned to align with fiber orientation when possible. Professional installations often include backing plates or reinforcement strips at mounting points to distribute fastener loads over larger areas. This approach prevents stress concentration that could lead to crack initiation around fastener holes.

Sealing and weatherproofing represent critical aspects of professional wheel tub installations. The interface between carbon fiber tubs and body panels must be carefully sealed to prevent water infiltration that could lead to corrosion or interior damage. Many professional installations utilize carbon fiber and fiberglass lay-up techniques to create seamless transitions between tubs and quarter panels. This approach eliminates visible seam lines while providing superior weather sealing.

Final alignment and adjustment procedures ensure that installed wheel tubs meet both functional and aesthetic requirements. The tubs must be positioned level and symmetrical relative to the vehicle centerline. Professional installers typically use precision measuring tools and reference strings to verify proper alignment before final fastening. Any misalignment discovered at this stage may require loosening fasteners and repositioning components before final tightening.

Quality control measures during final installation include comprehensive inspection of all mounting points, sealing interfaces, and clearance areas. Each mounting fastener should be torqued to specification using calibrated tools to ensure consistent clamping force. Sealant application should be uniform and complete, with excess material removed before curing to maintain professional appearance. Final clearance checks should verify adequate space for intended tire sizes under all anticipated operating conditions.

Safety Requirements and Regulations

Racing sanctioning bodies maintain strict safety requirements for wheel tub installations, with specific regulations varying between different racing classes and organizations. The National Hot Rod Association (NHRA) and International Hot Rod Association (IHRA) both maintain detailed technical regulations that govern wheel tub materials, construction methods, and installation requirements. Understanding and compliance with these regulations is mandatory for vehicles competing in sanctioned events and helps ensure participant safety during high-speed competition.

NHRA regulations specifically address carbon fiber components used in racing vehicles, requiring that all carbon fiber parts meet established safety standards and carry appropriate certifications. Carbon fiber wheel tubs must be manufactured from fire-retardant materials and include proper serial number identification for traceability. The regulations also specify minimum wall thickness requirements and construction methods that must be followed to ensure structural adequacy under racing conditions.

Installation safety requirements extend beyond simple material specifications to include proper mounting techniques and structural integration. Both NHRA and IHRA require that wheel tubs be securely mounted to the vehicle chassis using approved fastening methods. The mounting points must be capable of withstanding the extreme loads generated during high-speed racing without failure. Professional installations typically exceed minimum requirements by incorporating additional reinforcement and redundant attachment methods.

Fire safety considerations play a crucial role in wheel tub installation requirements. Racing regulations often require that wheel tubs be constructed from fire-retardant materials and designed to prevent fuel accumulation in wheel well areas. Proper drainage provisions must be incorporated to prevent fuel or other flammable liquids from collecting around wheel tubs. Some racing classes require additional fire suppression system integration with wheel tub installations.

Personal safety protocols during installation operations include proper handling of carbon fiber materials and use of appropriate protective equipment. Carbon fiber dust generated during cutting operations can pose serious respiratory hazards if proper precautions are not followed. Professional installers routinely use NIOSH-approved respirators and maintain adequate ventilation in work areas to prevent dust accumulation. Eye protection is mandatory when using power tools or cutting implements near carbon fiber components.

Structural safety considerations require that wheel tub installations maintain or enhance the vehicle's overall structural integrity. Modifications to frame rails or other chassis components must not compromise crash safety or structural adequacy. Professional installations typically include engineering analysis to verify that modifications meet or exceed original equipment strength requirements. This analysis may be required for certain racing classes or insurance purposes.

Quality assurance protocols ensure that completed installations meet all applicable safety requirements before vehicles are approved for competition. Many racing organizations require technical inspection of wheel tub installations before issuing competition approval. These inspections typically include verification of materials, construction methods, mounting techniques, and compliance with class-specific regulations. Professional installation shops often provide documentation packages that facilitate these inspection processes.

Maintenance and Care

Proper maintenance and care of carbon fiber wheel tubs ensures long-term performance, appearance retention, and structural integrity throughout their service life. Carbon fiber components require specific care procedures that differ significantly from traditional steel or aluminum parts, emphasizing gentle cleaning methods and protection against environmental degradation. Professional maintenance protocols can extend component life substantially while maintaining the premium appearance expected from high-end carbon fiber installations.

Cleaning procedures for carbon fiber wheel tubs must balance effectiveness with material protection, avoiding harsh chemicals or abrasive techniques that could damage the protective clear coat finish. The recommended cleaning process begins with thorough rinsing using clean, lukewarm water to remove loose dirt and debris before any physical contact with the surface. This initial rinse prevents scratching caused by abrasive particles during subsequent cleaning operations.

Professional cleaning protocols utilize pH-neutral automotive shampoo mixed with water and applied using soft microfiber towels. The cleaning motion should follow straight lines rather than circular patterns to minimize swirl mark creation on the carbon fiber surface. Multiple rinse cycles ensure complete removal of soap residue, which can cause water spotting or surface discoloration if allowed to dry on the component. Final drying should be performed using clean, dry microfiber towels rather than allowing air drying that can create mineral deposits.

Protective coating applications help maintain carbon fiber appearance and provide additional protection against environmental damage. UV-resistant sealants prevent yellowing and oxidation that can occur with prolonged sun exposure. Ceramic coatings offer superior long-term protection and can significantly reduce maintenance requirements while enhancing the visual depth of carbon fiber weave patterns. These protective coatings should be applied according to manufacturer specifications and renewed at recommended intervals.

Inspection procedures should be incorporated into regular vehicle maintenance schedules to identify potential issues before they develop into serious problems. Visual inspection should focus on mounting points, sealing interfaces, and areas subject to debris impact or environmental exposure. Any signs of delamination, cracking, or fastener loosening should be addressed immediately to prevent progressive damage that could compromise structural integrity or safety.

Environmental protection measures extend beyond simple cleaning to include consideration of storage conditions and exposure limitations. Carbon fiber components benefit from covered storage that protects against UV exposure when vehicles are not in active use. Temperature extremes and humidity variations should be minimized when possible, as these conditions can affect resin matrix stability over time. Professional race teams often maintain climate-controlled storage facilities specifically for carbon fiber component preservation.

Repair procedures for carbon fiber wheel tubs require specialized knowledge and materials that differ significantly from traditional metalworking techniques. Minor surface damage such as scratches or scuffs can often be addressed through careful polishing and clear coat restoration. More significant damage including cracks or delamination typically requires professional repair services using carbon fiber layup techniques and specialized adhesives. Attempting repairs without proper knowledge and materials can result in further damage or safety hazards.

Long-term maintenance planning should include consideration of component replacement schedules and upgrade opportunities. While carbon fiber wheel tubs are extremely durable, they are not permanent components and may eventually require replacement due to accumulated wear or damage. Professional installations often include documentation of component specifications and installation procedures to facilitate future service or replacement operations.

Cost Considerations

The financial aspects of carbon fiber wheel tub installation encompass both initial component costs and long-term value considerations that extend well beyond simple purchase price comparisons. Professional-quality carbon fiber wheel tubs typically cost between $925-$1,500 for a complete pair, representing a significant premium over aluminum alternatives. However, comprehensive cost analysis must include installation expenses, long-term maintenance requirements, and performance benefits that may justify the initial investment.

Material cost comparisons reveal the significant price differential between carbon fiber and traditional alternatives. Steel wheel tubs represent the most economical option but carry substantial weight penalties that can negatively impact vehicle performance. Aluminum tubs offer moderate weight savings at intermediate cost levels but may require more frequent replacement due to fatigue crack development over time. Carbon fiber commands premium pricing but provides superior strength-to-weight ratios and exceptional durability that can justify the investment in serious racing applications.

Installation costs vary significantly depending on the complexity of required chassis modifications and the skill level of personnel performing the work. Professional installation typically adds $1,000-$2,500 to the total project cost, reflecting the specialized knowledge and equipment required for proper installation. DIY installations can reduce labor costs but require significant time investment and carry risks of expensive mistakes that could exceed professional installation costs.

Hidden costs associated with wheel tub installation can significantly impact total project expenses if not properly anticipated. Chassis modifications may reveal additional issues requiring remedial work, such as rust repair or structural reinforcement that was not apparent during initial assessment. Paint and bodywork costs should be factored into project budgets, as wheel tub installations often require refinishing of adjacent areas to achieve professional appearance standards.

Long-term value considerations include reduced maintenance requirements and extended service life compared to traditional alternatives. Carbon fiber wheel tubs typically require minimal maintenance beyond regular cleaning and inspection, while aluminum alternatives may require periodic replacement due to fatigue cracking. The superior durability of carbon fiber can result in lower total cost of ownership despite higher initial investment, particularly in racing applications where component reliability is critical.

Performance value must be considered when evaluating the cost-effectiveness of carbon fiber wheel tub installations. The weight reduction achieved through carbon fiber components directly translates to improved acceleration, handling, and fuel economy. In competitive racing applications, these performance improvements can result in improved lap times and finishing positions that may have significant monetary value through prize money or sponsorship opportunities.

Resale value considerations favor carbon fiber installations in the high-performance vehicle market. Properly installed carbon fiber components often increase vehicle value by amounts approaching or exceeding their installation cost. This value retention makes carbon fiber wheel tubs attractive options for enthusiasts planning to sell or trade their vehicles in the future. Professional documentation of installation procedures and materials can enhance resale value by demonstrating quality workmanship and component provenance.

Insurance and financing considerations may affect the overall cost equation for carbon fiber wheel tub installations. Some insurance companies offer reduced premiums for vehicles equipped with safety-enhancing modifications, while others may require additional coverage for high-value aftermarket components. Financing options through specialty automotive lenders can help distribute installation costs over extended periods, making premium components more accessible to budget-conscious enthusiasts.

Common Installation Mistakes

Installation errors during carbon fiber wheel tub projects can result in compromised performance, safety hazards, and costly rework that far exceeds the original project budget. Understanding common mistakes and their prevention strategies enables both professional and DIY installers to avoid expensive problems that could damage components or compromise vehicle safety. Learning from industry experience can prevent repetition of errors that have plagued wheel tub installations throughout the evolution of this technology.

Template creation errors represent one of the most costly categories of installation mistakes, as they often remain undetected until expensive carbon fiber components have been cut to incorrect dimensions. The most common template error involves inadequate consideration of three-dimensional compound curves that cannot be accurately represented in flat cardboard patterns. Professional installers emphasize the importance of multiple test fittings with gradual template refinement rather than relying on initial measurements alone.

Inadequate clearance calculations frequently result in interference problems that may not become apparent until final assembly or initial testing. Static clearance measurements must account for suspension travel, tire growth at high speeds, and chassis flexing under load. Many installers make the mistake of calculating clearances based on static conditions alone, failing to consider dynamic factors that can reduce effective clearance during operation. Professional practice includes safety margins that account for these dynamic considerations.

Improper cutting techniques can destroy expensive carbon fiber components through delamination, edge fraying, or dimensional inaccuracy. The most common cutting error involves using inappropriate tools or techniques that cause fiber pullout or matrix cracking along cut edges. Professional cutting procedures emphasize proper tool selection, cutting speed control, and support techniques that minimize stress concentration during cutting operations.

Mounting and fastening errors can compromise both structural integrity and aesthetic appearance of completed installations. Over-tightening fasteners represents a common mistake that can cause stress concentration and eventual crack initiation in carbon fiber components. Conversely, under-tightening can allow component movement that leads to fatigue failure or joint separation. Professional installations specify proper torque values and use calibrated tools to ensure consistent fastener tension.

Inadequate surface preparation often results in poor adhesive bonds that can fail under service loads. The most common preparation error involves insufficient cleaning of bonding surfaces, leaving contamination that prevents proper adhesive adhesion. Oil, grease, paint residue, or even fingerprints can significantly reduce bond strength and lead to joint failure. Professional preparation protocols include solvent cleaning and light abrasion to ensure optimal bonding conditions.

Sealing and weatherproofing mistakes can allow water infiltration that leads to corrosion, interior damage, or component degradation over time. Common sealing errors include inadequate coverage, improper material selection, or failure to account for thermal expansion and contraction. Professional installations use appropriate sealants applied in sufficient quantities to ensure complete coverage while maintaining flexibility for thermal cycling.

Quality control oversights allow defects or problems to remain undetected until they develop into serious issues during service. Many installers fail to perform comprehensive final inspections that verify all aspects of the installation meet professional standards. Systematic inspection procedures should include verification of clearances, fastener torque, sealing integrity, and overall installation quality before considering the project complete.

Documentation failures prevent effective troubleshooting or future maintenance when issues arise. Many installations lack adequate photographic documentation or written records of procedures, materials, and specifications used during installation. Professional installations include comprehensive documentation packages that facilitate future service, warranty claims, or technical inspection requirements.

Professional vs DIY Installation

The decision between professional installation and do-it-yourself approaches for carbon fiber wheel tubs involves careful consideration of technical complexity, available resources, and risk tolerance factors that vary significantly among individual situations. Professional installation offers expertise, specialized equipment, and warranty protection but commands premium pricing that may exceed DIY costs by substantial margins. Conversely, DIY installation provides cost savings and personal satisfaction but requires significant skill development and carries risks of expensive mistakes.

Technical complexity assessment reveals that carbon fiber wheel tub installation demands skills spanning multiple automotive disciplines including metalworking, composites handling, precision measuring, and finish work. Professional installers typically possess years of experience working with carbon fiber materials and have developed specialized techniques for achieving consistently excellent results. The learning curve for DIY installers can be steep, particularly for individuals without prior experience in automotive fabrication or composite materials handling.

Specialized equipment requirements often favor professional installation approaches, as many necessary tools represent significant investments that may not be justified for single-use applications. Professional shops maintain complete inventories of cutting tools, measuring instruments, fastening hardware, and safety equipment specifically designed for carbon fiber work. DIY installers may need to purchase or rent specialized equipment, potentially reducing the cost advantage of self-installation approaches.

Time investment considerations strongly favor experienced professional installers who can complete installations efficiently while maintaining quality standards. Professional installations typically require 13-20 total hours spread across multiple days, while DIY projects often extend significantly longer due to learning curves and potential rework requirements. The opportunity cost of extended DIY installation time may exceed professional installation costs for individuals with high-value alternative time uses.

Risk assessment reveals significant differences in potential consequences between professional and DIY installation approaches. Professional installers typically carry insurance coverage that protects against errors or accidents during installation, while DIY installers assume full responsibility for any problems that arise. The cost of correcting mistakes made during DIY installations can quickly exceed professional installation costs, particularly if expensive carbon fiber components are damaged beyond repair.

Quality assurance standards differ significantly between professional and DIY installation approaches. Professional installations often include formal inspection procedures, documented quality control measures, and warranty coverage that provides long-term protection. DIY installations rely entirely on the individual installer's knowledge and attention to detail, with no external verification of work quality or long-term performance guarantees.

Warranty and support considerations favor professional installations that typically include guarantees against defects or problems related to installation workmanship. Professional installers also provide ongoing support for questions or issues that may arise during vehicle operation. DIY installers must rely on their own troubleshooting abilities and may have difficulty obtaining technical support from component manufacturers if problems develop.

Long-term value propositions require consideration of factors beyond initial cost savings. Professional installations often add more value to vehicles than their installation cost, while poor-quality DIY work may actually reduce vehicle value. Additionally, professional documentation and warranty coverage can enhance resale value and provide reassurance to potential buyers that work was performed to industry standards.

Educational value represents a significant benefit of DIY installation approaches for individuals interested in learning automotive fabrication techniques. The hands-on experience gained through wheel tub installation can provide valuable knowledge applicable to future projects and hobby interests. However, this educational value must be weighed against the risks and potential costs associated with learning on expensive components.

Troubleshooting Common Issues

Troubleshooting problems that arise during or after carbon fiber wheel tub installation requires systematic diagnostic approaches combined with understanding of common failure modes and their underlying causes. Early identification and resolution of issues prevents minor problems from developing into major complications that could compromise safety or require expensive remedial work. Professional troubleshooting techniques emphasize methodical problem isolation and root cause analysis rather than symptomatic treatment approaches.

Fitment problems represent the most common category of issues encountered during wheel tub installation, often stemming from measurement errors or inadequate template creation during earlier installation phases. Interference between tubs and suspension components typically indicates insufficient clearance calculations or failure to account for suspension travel ranges. Resolution usually requires careful material removal from interference areas, though excessive removal can compromise structural integrity and may necessitate component replacement.

Clearance issues with tire contact can develop gradually as tires wear or vehicle setup changes occur. Initial clearance calculations must account for tire diameter variations due to wear patterns, inflation pressure changes, and centrifugal growth during high-speed operation. Troubleshooting tire clearance problems requires systematic measurement of actual clearances under various operating conditions, including suspension compression and tire growth scenarios.

Mounting and fastening problems often manifest as component movement, unusual noises, or visible signs of stress concentration around attachment points. Loose fasteners can develop due to inadequate initial torque, thermal cycling, or vibration-induced loosening. Systematic inspection of all mounting points should include verification of fastener torque using calibrated tools and examination for signs of stress concentration or material damage around fastener locations.

Sealing failures typically become apparent through water infiltration, rust development, or interior moisture problems. Poor sealing can result from inadequate material application, inappropriate sealant selection, or failure to account for thermal expansion and movement. Troubleshooting sealing problems requires systematic inspection of all joint interfaces and identification of infiltration paths through tracer testing or visual examination during water application.

Structural problems including cracking or delamination require immediate attention to prevent progressive failure that could compromise safety. Carbon fiber damage typically propagates rapidly once initiated, making early detection and repair critical. Professional evaluation is often required to assess the extent of structural damage and determine appropriate repair procedures or component replacement requirements.

Aesthetic issues such as surface damage, discoloration, or poor finish quality can often be resolved through proper restoration techniques. Surface scratches may be removable through careful polishing procedures, while more significant damage may require professional repair services. UV-induced discoloration or clear coat degradation typically requires complete refinishing to restore original appearance standards.

Performance degradation problems may develop over time due to component wear, mounting system changes, or vehicle setup modifications. Systematic performance evaluation should include measurement of relevant parameters such as weight distribution, clearance margins, and structural integrity indicators. Comparison with documented baseline measurements can help identify specific areas requiring attention or adjustment.

Environmental damage from exposure to chemicals, road salt, or extreme weather conditions can affect both appearance and structural integrity of carbon fiber components. Troubleshooting environmental damage requires assessment of exposure conditions and implementation of appropriate protective measures to prevent further degradation. Professional consultation may be required for severe damage assessment and repair planning.

Regulatory compliance issues can develop when vehicle modifications affect safety equipment or racing classification requirements. Troubleshooting compliance problems requires review of applicable regulations and comparison with actual vehicle configuration. Resolution may require component modifications or additional safety equipment installation to meet regulatory requirements.

Documentation and traceability problems can complicate troubleshooting efforts when adequate installation records are unavailable. Professional troubleshooting often relies on detailed documentation of original installation procedures, materials, and specifications. Recreating missing documentation may be necessary to support effective problem diagnosis and resolution planning.

Conclusion and Final Tips

The installation of carbon fiber wheel tubs represents a sophisticated automotive modification that demands careful planning, precise execution, and ongoing maintenance to achieve optimal results. This comprehensive guide has outlined the four critical steps necessary for successful installation: thorough planning and preparation, methodical removal and frame modification, precise template creation and fitting, and professional-quality final installation and mounting. Each phase contributes essential elements to the overall project success and cannot be abbreviated without compromising final results.

Professional-quality results require attention to details that extend beyond basic installation procedures to encompass safety protocols, regulatory compliance, and long-term maintenance considerations. The investment in carbon fiber wheel tubs, typically ranging from $925-$1,500 for components alone, demands installation techniques that protect this investment while maximizing performance benefits. Proper installation not only ensures immediate functionality but also provides the durability and reliability expected from premium composite components.

The technical complexity of carbon fiber wheel tub installation makes professional installation the preferred choice for most applications, despite higher initial costs. Professional installers possess specialized knowledge, appropriate equipment, and warranty backing that provides long-term value beyond simple cost savings. However, experienced DIY enthusiasts with appropriate skills and equipment can achieve excellent results through careful adherence to professional procedures and quality standards.

Safety considerations must remain paramount throughout all phases of wheel tub installation, from initial planning through final inspection and testing. The use of appropriate personal protective equipment, proper ventilation, and fire safety precautions protects both personnel and property during installation operations. Compliance with racing regulations ensures that completed installations meet sanctioning body requirements for competitive use.

Long-term success with carbon fiber wheel tubs depends heavily on proper maintenance and care procedures that preserve both appearance and structural integrity throughout the component's service life. Regular cleaning with appropriate materials, protection against UV exposure, and systematic inspection for damage or wear help maximize the return on investment in these premium components.

The performance benefits achievable through carbon fiber wheel tub installation justify the investment for serious racing applications where weight reduction and strength are critical factors. The exceptional strength-to-weight ratio of carbon fiber enables larger tire clearances without corresponding weight penalties, directly translating to improved traction and performance capabilities. These benefits become increasingly important as racing speeds and competition levels increase.

Future developments in carbon fiber technology and manufacturing techniques promise continued improvements in component quality, installation ease, and cost-effectiveness. Staying informed about industry developments and emerging best practices helps ensure that installations remain current with evolving standards and capabilities. Professional installers often provide valuable insights into emerging technologies and techniques that can benefit both current and future projects.

The decision to install carbon fiber wheel tubs should be based on comprehensive evaluation of performance requirements, budget constraints, and long-term objectives rather than simple aesthetic considerations. While the visual appeal of carbon fiber is undeniable, the substantial investment requires justification through tangible performance improvements and enhanced vehicle capabilities. Careful consideration of all factors discussed in this guide helps ensure that the installation decision aligns with individual needs and expectations.

Success with carbon fiber wheel tub installation ultimately depends on commitment to quality throughout all phases of the project, from initial planning through long-term maintenance. Professional standards, appropriate materials, and careful attention to detail produce installations that provide years of reliable service while maintaining the premium appearance expected from high-end carbon fiber components. This comprehensive approach ensures that the substantial investment in carbon fiber technology delivers the expected performance benefits and aesthetic satisfaction for years to come.