Why Use Carbon Fiber Wheels: The Ultimate Performance Enhancement for Modern Vehicles

Carbon fiber wheels represent one of the most significant technological advances in automotive engineering, transforming how vehicles perform across every measurable metric from acceleration to fuel efficiency. What began as an exclusive technology reserved for Formula 1 racing cars and million-dollar supercars has evolved into an accessible upgrade that's revolutionizing the driving experience for enthusiasts worldwide.

The fundamental appeal of carbon fiber lies in its unprecedented combination of strength and lightness. Unlike traditional materials that force engineers to choose between durability and weight savings, carbon fiber delivers both simultaneously. This revolutionary composite material consists of thousands of carbon atoms bonded together in a crystalline structure, creating a material that's 13 times stronger than aluminum while weighing approximately 50% less. When applied to wheel construction, these properties translate into dramatic improvements in vehicle performance that extend far beyond simple weight reduction.

What Makes Carbon Fiber Special in Automotive Applications

The unique properties of carbon fiber stem from its molecular structure. Each carbon fiber strand is thinner than a human hair yet possesses incredible tensile strength. When these fibers are woven together and bonded with specialized resins, they create a composite material with directional strength characteristics that can be precisely engineered for specific applications. In wheel manufacturing, this allows engineers to place strength exactly where it's needed while minimizing material usage in non-critical areas.

Carbon fiber's vibration damping properties set it apart from metallic alternatives. The material naturally absorbs high-frequency vibrations while allowing important tactile feedback to reach the driver. This characteristic creates a smoother, more refined driving experience while simultaneously protecting vehicle components from fatigue-inducing vibrations that can reduce their lifespan over time.

Evolution from Racing to Consumer Markets

The journey of carbon fiber wheels from racing exclusivity to consumer availability reflects the broader democratization of advanced automotive technology. Formula 1 teams first adopted carbon fiber wheels in the 1980s, recognizing that every gram of weight reduction could translate into measurable lap time improvements. The technology's success in motorsports gradually filtered down through high-end supercars, luxury vehicles, and ultimately to performance-oriented consumer applications.

Modern manufacturing advances have dramatically reduced production costs while maintaining the quality standards demanded by automotive applications. Techniques such as resin transfer molding and automated fiber placement have streamlined production processes, making carbon fiber wheels increasingly accessible to driving enthusiasts who demand the ultimate in performance technology.

The Science Behind Carbon Fiber Wheel Performance

Understanding why carbon fiber wheels deliver such dramatic performance improvements requires examining the material science that makes these benefits possible. The manufacturing process itself plays a crucial role in determining the final wheel's characteristics, with different construction methods offering varying balances of performance, durability, and cost effectiveness.

Material Composition and Manufacturing Process

Carbon fiber wheel production begins with selecting appropriate fiber types and resin systems. High-quality manufacturers utilize aerospace-grade materials such as Toray T700S carbon fiber, which provides exceptional tensile strength and consistency. The manufacturing process involves laying multiple carbon fiber layers in specific orientations to optimize strength characteristics for the unique stresses that wheels encounter during operation.

The precision required in carbon fiber wheel manufacturing cannot be overstated. Each wheel may contain over 500 individual carbon fiber pieces, meticulously positioned to create optimal strength distribution. The layup process requires skilled technicians working in controlled environments to ensure proper fiber alignment and resin saturation. Temperature and humidity control during this phase directly impacts the final product's quality and performance characteristics.

Pre-preg vs Wet Layup Construction Methods

Two primary manufacturing approaches dominate carbon fiber wheel production, each offering distinct advantages. Pre-preg (pre-impregnated) carbon fiber arrives with resin already embedded in the fibers, providing superior quality control and consistency. This method requires frozen storage and has limited working time once removed from refrigeration, but delivers exceptional strength-to-weight ratios and surface finish quality.

Wet layup techniques involve applying liquid resin to dry carbon fiber during the manufacturing process. While this method offers greater flexibility in production scheduling and lower material costs, it requires exceptional skill to achieve consistent results. The resin application must be precisely controlled to avoid dry spots or resin-rich areas that could compromise structural integrity.

Strength-to-Weight Ratio Analysis

The exceptional strength-to-weight ratio of carbon fiber wheels becomes apparent when comparing material properties. Carbon fiber composites achieve tensile strengths exceeding 3,500 MPa while maintaining densities around 1.6 g/cm³. In contrast, aluminum alloys typically achieve tensile strengths around 310 MPa with densities of 2.7 g/cm³. This means carbon fiber delivers more than 10 times the strength per unit weight compared to aluminum.

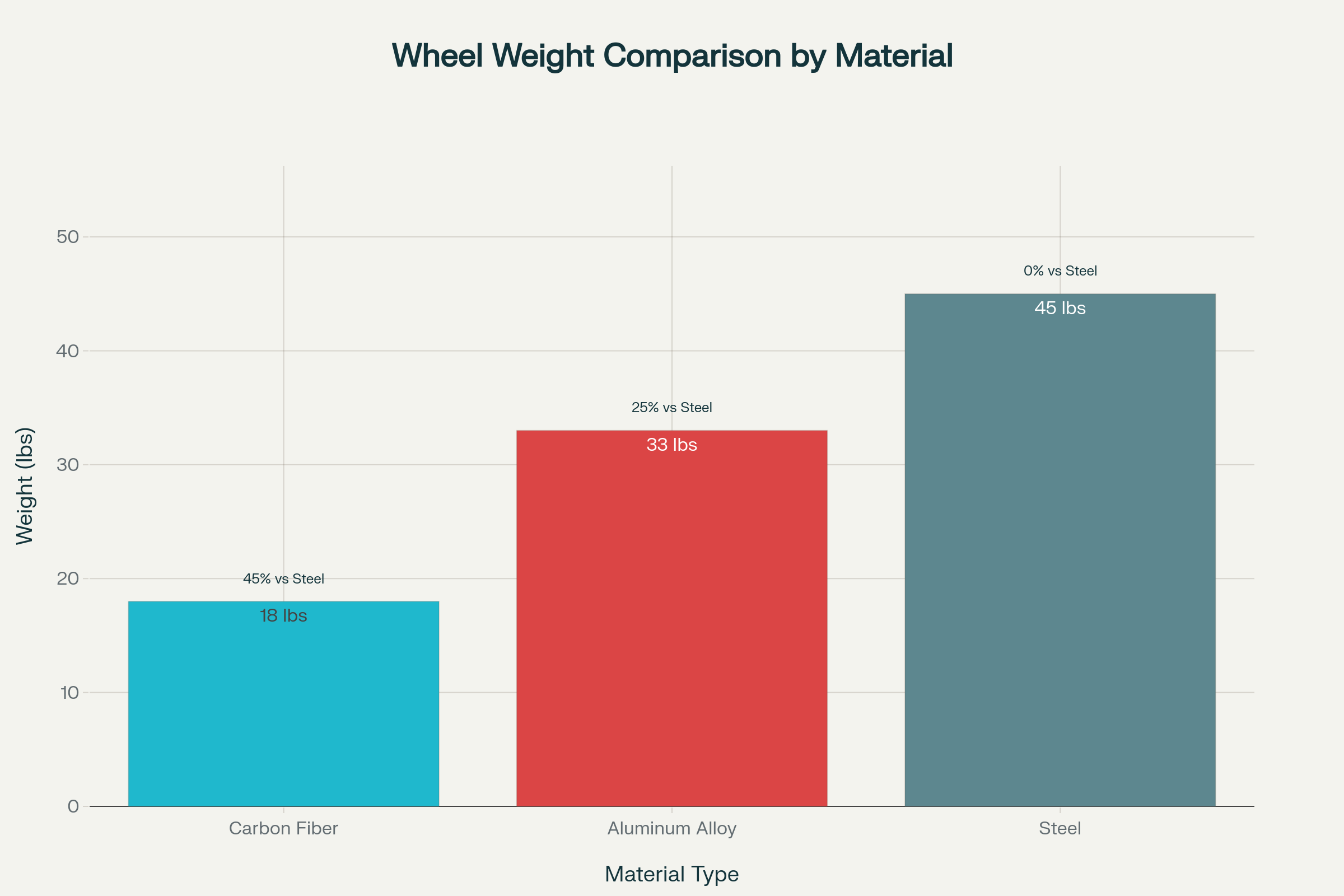

These material advantages translate directly into wheel performance benefits. A typical carbon fiber wheel weighs approximately 18 pounds compared to 33 pounds for an equivalent aluminum wheel. This 45% weight reduction occurs in the most critical location – the unsprung mass that directly affects suspension performance, acceleration, braking, and handling characteristics.

Fatigue Resistance vs Traditional Materials

Unlike metallic materials that gradually weaken under repeated stress cycles, carbon fiber exhibits exceptional fatigue resistance. The composite structure distributes loads across multiple fiber orientations, preventing the crack propagation that limits metal component lifecycles. Industry testing demonstrates that well-constructed carbon fiber wheels can handle approximately three times more stress cycles than magnesium racing wheels before showing signs of fatigue.

This fatigue resistance translates into exceptional longevity. Many carbon fiber wheels continue performing optimally after 100,000 miles or more of service, with some manufacturers offering 10-year warranties compared to the typical 5-year coverage for aluminum alternatives. The material's resistance to corrosion further extends service life, with testing showing carbon fiber wheels corroding at only 0.003% per year compared to aluminum's 0.12% rate when exposed to salt spray conditions.

Dramatic Weight Reduction Benefits

The weight reduction achieved through carbon fiber wheel adoption creates a cascading series of performance improvements that touch every aspect of vehicle dynamics. Understanding unsprung weight's role in vehicle performance explains why carbon fiber wheels deliver such dramatic improvements despite representing a relatively small percentage of total vehicle weight.

Unsprung Weight Impact on Vehicle Dynamics

Unsprung weight consists of components not supported by the vehicle's suspension system, including wheels, tires, brakes, and portions of the suspension components themselves. This weight directly opposes the suspension's ability to maintain tire contact with the road surface, particularly over irregular pavement. Reducing unsprung weight allows the suspension to respond more quickly to surface changes, improving both handling precision and ride quality.

The rotational inertia reduction from lighter wheels proves equally significant. Carbon fiber wheels reduce rotational inertia by approximately 27% compared to aluminum alternatives. This reduction means less energy is required to accelerate or decelerate the wheels, improving both acceleration and braking performance while reducing the load on drivetrain components.

Acceleration and Braking Performance Improvements

Real-world testing consistently demonstrates measurable performance improvements from carbon fiber wheel adoption. Vehicles equipped with carbon fiber wheels typically achieve 0-60 mph times that are 0.3 seconds quicker than identical vehicles with aluminum wheels. This improvement stems from reduced rotational inertia and lower overall vehicle weight, allowing more engine power to translate into forward motion rather than accelerating wheel mass.

Braking improvements prove equally dramatic. Testing shows braking distances shrink by approximately 8%, translating to roughly 26 feet less stopping distance at highway speeds. The reduced momentum from lighter wheels means less kinetic energy must be dissipated during braking, reducing stress on brake components and improving fade resistance during repeated stops.

Real-World Performance Data and Testing Results

Professional testing validates the theoretical advantages of carbon fiber wheels across multiple performance metrics. Track testing at demanding circuits like the Nürburgring demonstrates lap time improvements of nearly 0.5 seconds per lap when switching from aluminum to carbon fiber wheels. These improvements result from the combination of reduced unsprung weight, improved acceleration, shorter braking distances, and enhanced handling precision.

The benefits extend beyond pure performance metrics. Fuel economy improvements of 5-8% are commonly observed, resulting from reduced vehicle weight and improved aerodynamics. For daily driving, this translates into measurable savings at the fuel pump while simultaneously reducing environmental impact through lower emissions.

Superior Handling and Control Characteristics、

Carbon fiber wheels transform vehicle handling characteristics through multiple mechanisms that work synergistically to improve driver control and vehicle responsiveness. The combination of reduced unsprung weight, enhanced stiffness, and superior damping properties creates a driving experience that many describe as transformational.

Reduced Rotational Inertia Effects

The rotational inertia reduction from carbon fiber wheels affects vehicle behavior in ways that extend far beyond straight-line acceleration. When cornering, lighter wheels require less force to change direction, improving the vehicle's ability to follow steering inputs precisely. This characteristic becomes particularly apparent during rapid direction changes or when navigating technical driving situations where precise control is essential.

Professional drivers consistently report improved vehicle responsiveness when switching to carbon fiber wheels. Steering response times improve by 15-22 milliseconds, which translates to approximately 1.3 degrees sharper steering response at highway speeds. While these improvements might seem subtle on paper, the cumulative effect creates a more connected, confidence-inspiring driving experience.

Enhanced Steering Response and Precision

The superior stiffness of carbon fiber wheels contributes significantly to improved steering precision. Carbon fiber wheels typically exhibit 40% greater stiffness than forged aluminum counterparts. This increased stiffness ensures that steering inputs translate more directly into tire movement, reducing the lag and imprecision that can result from wheel flex under cornering loads.

Vibration damping properties further enhance the driving experience. Carbon fiber's natural ability to absorb high-frequency vibrations while transmitting important road feedback creates an optimal balance between comfort and communication. Drivers report feeling more connected to the road surface while experiencing reduced fatigue during extended driving sessions.

Track Performance Advantages

On racing circuits, carbon fiber wheels deliver measurable performance advantages that professional drivers and serious enthusiasts can exploit. Track testing demonstrates that cars equipped with carbon fiber wheels navigate corners 18% quicker at challenging sections like Silverstone's Copse Corner. This improvement results from the combination of reduced unsprung weight, improved tire contact, and enhanced steering precision.

The thermal management benefits of carbon fiber wheels become particularly apparent during track use. Unlike aluminum wheels that can conduct heat from brake components, carbon fiber's low thermal conductivity helps maintain more stable tire pressures and consistent handling characteristics during extended high-performance driving sessions.

Advanced Heat Management Properties

Carbon fiber wheels offer unique thermal management characteristics that provide significant advantages in high-performance driving situations. Understanding these thermal properties explains why carbon fiber wheels maintain consistent performance under conditions that would compromise traditional wheel materials.

Thermal Conductivity Benefits for Brake Systems

Carbon fiber's low thermal conductivity (15 W/mK compared to aluminum's 205 W/mK) provides crucial benefits for brake system performance. While aluminum wheels readily conduct heat from brake components, carbon fiber wheels act as thermal insulators, helping maintain more stable brake temperatures during aggressive driving. This characteristic reduces brake fade and helps preserve brake component longevity.

The thermal isolation provided by carbon fiber wheels also benefits tire performance. By minimizing heat transfer from hot brake components, carbon fiber wheels help maintain more consistent tire pressures and temperatures. This stability translates into more predictable handling characteristics and improved tire longevity, particularly during track driving or spirited road use.

Temperature Stability Under Extreme Conditions

Carbon fiber wheels maintain their structural integrity and performance characteristics across a much wider temperature range than metallic alternatives. Testing demonstrates that carbon fiber wheels perform consistently from -40°F to 300°F, making them suitable for extreme climate conditions and high-performance applications. This temperature stability ensures consistent wheel performance regardless of environmental conditions or driving intensity.

The minimal thermal expansion of carbon fiber (0.5 parts per million per degree Celsius compared to aluminum's 23.1 ppm/°C) helps maintain precise tire-to-wheel fit and consistent handling characteristics as temperatures vary. This stability is particularly beneficial during track driving, where brake heat and ambient temperature changes can significantly affect wheel dimensions and performance.

Long-Term Durability and Maintenance

Contrary to common misconceptions about carbon fiber fragility, properly manufactured carbon fiber wheels offer exceptional durability and longevity when maintained according to manufacturer specifications. Understanding the unique characteristics of carbon fiber helps owners maximize their investment while enjoying decades of superior performance.

Fatigue Resistance and Lifespan Expectations

Carbon fiber's composite structure provides inherent advantages in fatigue resistance compared to metallic materials. Unlike metals that gradually weaken under repeated stress cycles, carbon fiber maintains its structural integrity virtually indefinitely when loads remain within design parameters. This characteristic means that well-maintained carbon fiber wheels can potentially last the lifetime of the vehicle with proper care and handling.

Real-world examples support these theoretical advantages. Documented cases include riders accumulating over 122,000 miles on BST carbon fiber motorcycle wheels without significant degradation. Similar longevity is reported in automotive applications, with many carbon fiber wheels continuing to perform optimally after 150,000+ miles of service.

Proper Care and Maintenance Procedures

Maintaining carbon fiber wheels requires understanding their unique characteristics and following appropriate care procedures. Regular cleaning with pH-neutral, non-abrasive cleaners helps preserve the protective clear coat and underlying carbon fiber structure. Avoiding harsh chemicals, high-pressure washing directly on the wheel surface, and abrasive cleaning materials helps ensure long-term durability.

Visual inspection plays a crucial role in carbon fiber wheel maintenance. Unlike metallic wheels that may dent or bend under impact, carbon fiber wheels can develop internal damage that's not immediately visible. Regular inspection for chips, cracks, or delamination helps identify potential issues before they compromise safety or performance. Professional inspection following any significant impact is recommended to ensure continued structural integrity.

Cost-Benefit Analysis Over Vehicle Lifetime

While carbon fiber wheels require a significant initial investment, their long-term cost-effectiveness becomes apparent when considering their extended lifespan and performance benefits. Leading manufacturers now offer 10-year warranties compared to typical 5-year coverage for aluminum wheels. This extended warranty coverage reflects manufacturer confidence in the material's durability and longevity.

The performance benefits of carbon fiber wheels can also contribute to reduced operating costs. Improved fuel economy, reduced tire wear from better handling characteristics, and decreased stress on suspension components can offset the initial investment over the wheel's service life. For performance vehicle owners, the enhanced driving experience and potential resale value benefits provide additional justification for the investment.

Carbon Fiber Wheel Types and Construction

The carbon fiber wheel market offers various construction approaches, each optimized for specific applications and performance requirements. Understanding these different approaches helps buyers select wheels that best match their intended use and performance expectations.

Monoblock vs Multi-piece Designs

Monoblock (one-piece) construction represents the pinnacle of carbon fiber wheel engineering, with the entire wheel manufactured as a single integrated unit. This approach maximizes strength while minimizing weight, as there are no joints or fasteners that could add mass or create potential failure points. Monoblock carbon fiber wheels typically offer the best strength-to-weight ratio and are preferred for high-performance applications where ultimate performance is the primary consideration.

Multi-piece carbon fiber wheels combine carbon fiber construction with aluminum or other materials to balance performance, cost, and repairability. These designs might feature carbon fiber barrels with aluminum centers, or carbon fiber faces with aluminum backing structures. While potentially heavier than full carbon monoblock designs, multi-piece wheels can offer advantages in terms of repairability and customization options.

Manufacturing Quality Standards and Testing

Carbon fiber wheel manufacturing requires adherence to stringent quality standards and testing protocols to ensure safety and performance. SAE J3204 standards specifically address composite wheel testing requirements, including fatigue testing, impact resistance, and maximum operating temperature verification. These standards ensure that carbon fiber wheels meet the same safety requirements as traditional metallic wheels while accounting for the unique characteristics of composite materials.

Advanced testing methods validate carbon fiber wheel durability and safety. BIAX testing fixtures can simulate virtually any driving condition, from extreme track use to everyday road driving, ensuring wheels can withstand the stresses they'll encounter in real-world use. Additional testing includes impact resistance, thermal cycling, and long-term fatigue testing that may exceed 1 million load cycles to verify durability.

Investment Considerations and Value Proposition

Carbon fiber wheels represent a significant financial investment that requires careful consideration of costs, benefits, and intended applications. Understanding the value proposition helps potential buyers make informed decisions about whether carbon fiber wheels align with their performance goals and budget constraints.

Initial Cost vs Long-term Benefits

Carbon fiber wheels typically command premium pricing, with high-end options ranging from $4,000-$6,000 per wheel. Entry-level carbon fiber wheels may be available for $1,000-$2,000 per wheel, though these often involve compromises in manufacturing quality or performance characteristics. When compared to premium forged aluminum wheels that might cost $500-$1,500 per wheel, the initial investment differential is substantial.

However, the long-term value proposition becomes more attractive when considering durability and performance benefits. Carbon fiber wheels' extended lifespan (200,000+ miles vs 120,000 miles for aluminum) and potential fuel economy improvements can offset some of the initial cost differential. For performance vehicle owners who value the driving experience enhancement, the cost-per-benefit calculation often favors carbon fiber wheels.

Performance Vehicle Applications

Carbon fiber wheels deliver the greatest value in performance vehicle applications where their benefits can be fully exploited. Sports cars, track-focused vehicles, and high-performance luxury cars represent ideal applications where the performance improvements justify the investment. The weight reduction and handling improvements become particularly apparent in vehicles designed to exploit these characteristics.

Racing and motorsports applications represent another area where carbon fiber wheels provide exceptional value. The competitive advantages from reduced lap times and improved vehicle dynamics can justify the investment for serious competitors. Professional racing series increasingly mandate or encourage carbon fiber wheel use, recognizing their performance benefits and safety characteristics.

Motorsports and Professional Racing Usage

Professional motorsports provide the ultimate validation of carbon fiber wheel technology. Formula 1, MotoGP, and numerous professional racing series rely on carbon fiber wheels for their combination of strength, lightness, and performance consistency. The extreme conditions of professional racing push these wheels far beyond typical street use, proving their durability and reliability under the most demanding circumstances.

The trickle-down effect from professional racing continues to drive innovation in consumer carbon fiber wheels. Technologies developed for racing applications gradually become available in street-legal versions, providing consumers access to proven performance enhancements developed in the world's most demanding testing environment.

Environmental Impact and Sustainability

As environmental consciousness grows within the automotive industry, the sustainability aspects of carbon fiber wheels merit consideration. While carbon fiber production involves energy-intensive processes, the complete lifecycle assessment presents a more complex environmental picture.

Recyclability and Environmental Footprint

Carbon fiber recycling presents challenges compared to traditional materials like aluminum, which can be recycled repeatedly with minimal energy input. However, advanced recycling techniques are emerging that can reclaim carbon fibers for use in new applications. Some manufacturers now offer 100% recyclable carbon fiber wheels, though the recycling infrastructure remains limited compared to metallic alternatives.

The environmental impact assessment must consider the complete product lifecycle, including the performance benefits that carbon fiber wheels provide. Improved fuel economy from reduced vehicle weight can offset some of the manufacturing environmental impact through reduced emissions over the wheel's service life. For electric vehicles, the weight reduction from carbon fiber wheels directly translates into extended driving range and reduced energy consumption.

Future Technology Trends

The carbon fiber wheel industry continues evolving with advancing manufacturing technologies and growing market acceptance. Market analysis predicts 9.3% annual growth through 2035, driven by increasing demand for lightweight, high-performance vehicle components. Automotive manufacturers are increasingly incorporating carbon fiber wheels as standard equipment on high-end models, reflecting growing confidence in the technology.

Emerging manufacturing techniques promise to reduce costs while maintaining quality standards. Automated fiber placement and advanced resin systems are streamlining production processes, potentially making carbon fiber wheels more accessible to broader market segments. Partnerships between traditional wheel manufacturers and carbon fiber specialists are accelerating technology development and market adoption.

Conclusion: Making the Decision for Carbon Fiber Wheels

Carbon fiber wheels represent a transformational upgrade that delivers measurable improvements across virtually every aspect of vehicle performance. The combination of dramatic weight reduction, superior strength characteristics, enhanced handling precision, and exceptional durability creates a compelling value proposition for drivers seeking the ultimate in wheel technology.

The decision to invest in carbon fiber wheels ultimately depends on individual priorities, intended vehicle use, and budget considerations. For performance vehicle enthusiasts, track drivers, and those who value cutting-edge technology, carbon fiber wheels offer benefits that justify their premium pricing. The measurable improvements in acceleration, braking, handling, and fuel economy provide tangible benefits that enhance both performance and daily driving experiences.

As manufacturing technology continues advancing and production costs decrease, carbon fiber wheels are becoming increasingly accessible to broader segments of the automotive market. The combination of proven performance benefits, improving cost-effectiveness, and growing manufacturer support positions carbon fiber wheels as a compelling upgrade for discerning drivers seeking the ultimate in automotive technology.

Whether pursuing lap time improvements on track days, seeking enhanced daily driving dynamics, or simply wanting access to the latest automotive technology, carbon fiber wheels deliver benefits that transform the driving experience. The investment in carbon fiber wheel technology represents not just a purchase, but an investment in superior performance, advanced engineering, and driving satisfaction that extends far beyond simple transportation.

For those ready to experience the transformative benefits of carbon fiber wheel technology, AME Motorsport offers a comprehensive selection of premium carbon fiber wheels designed to deliver the ultimate in performance, quality, and driving satisfaction. The future of wheel technology is here – and it's lighter, stronger, and more capable than ever before.