What Happens If You Curb a Carbon Fiber Wheel: Complete Guide to Damage, Risks, and Solutions

Introduction: The Reality of Carbon Fiber Wheel Damage

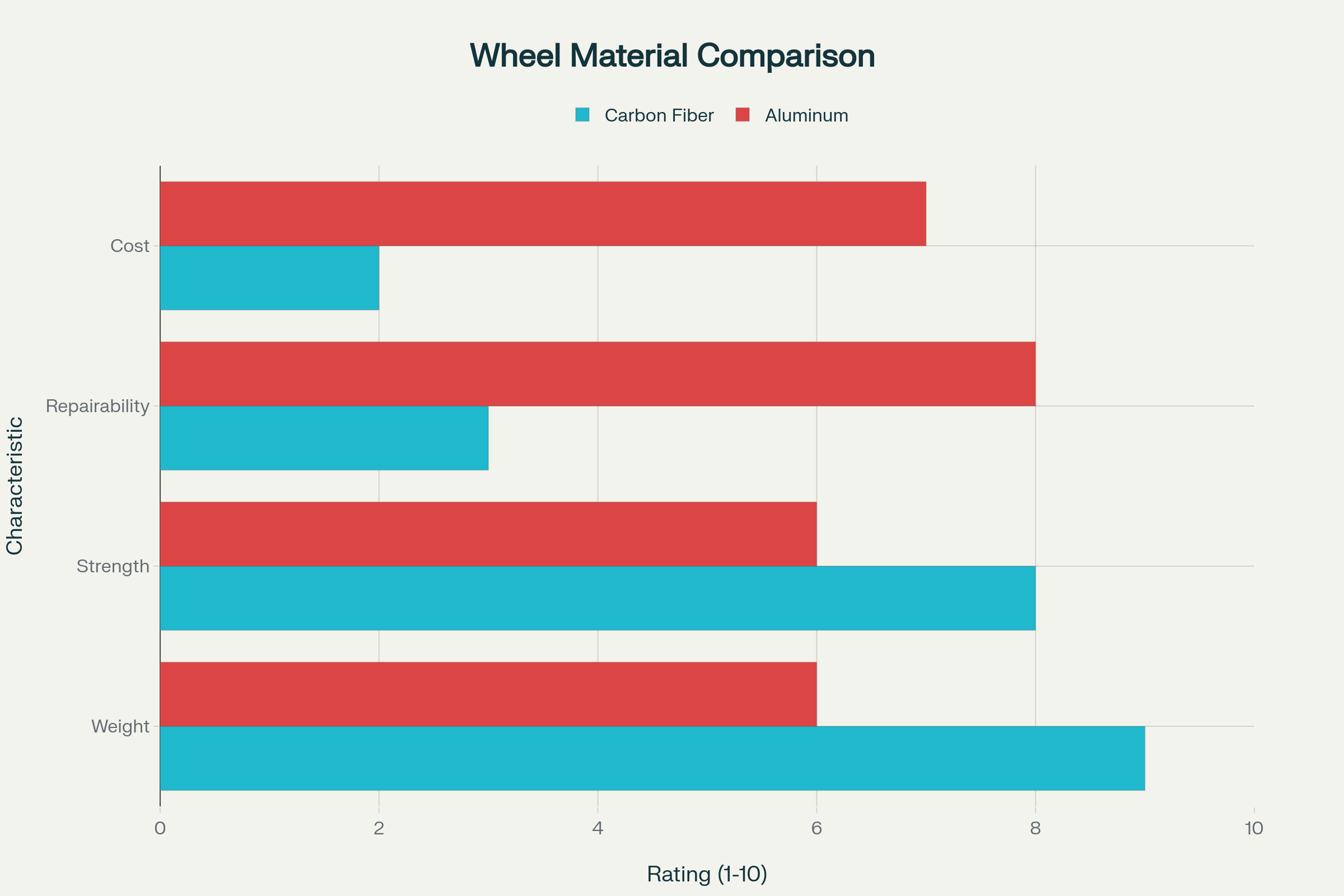

Curbing a carbon fiber wheel isn't just an expensive mistake—it's a potential safety hazard that every high-performance vehicle owner needs to understand. Unlike traditional aluminum or steel wheels that might bend or dent when hitting a curb, carbon fiber wheels react completely differently to impact damage. The consequences can range from minor cosmetic issues to catastrophic structural failure, making it crucial for owners to recognize the signs and understand their options.

Why Carbon Fiber Wheels Are Different

Carbon fiber wheels represent the pinnacle of automotive wheel technology, offering exceptional strength-to-weight ratios and superior performance characteristics. However, their composite construction fundamentally changes how they respond to damage compared to traditional metal wheels. While metal wheels typically deform gradually under stress, carbon fiber wheels maintain their structural integrity until they reach a critical failure point—then they fail suddenly and catastrophically.

The material properties of carbon fiber create a unique challenge: the wheels are incredibly strong in their intended load directions but can be surprisingly vulnerable to certain types of impacts. Understanding this difference is essential for anyone considering or currently owning carbon fiber wheels.

The Expensive Reality of Curb Damage

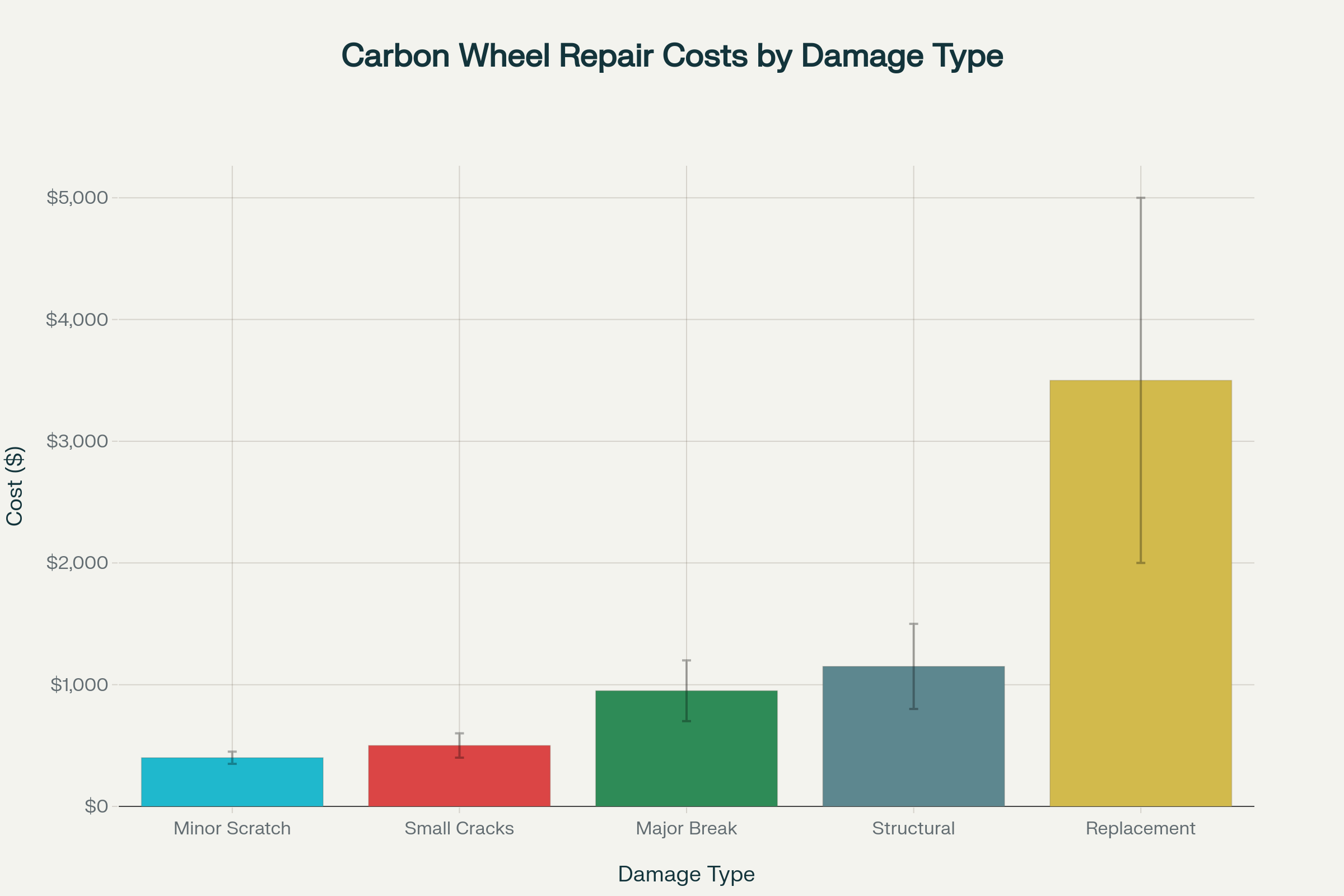

When you curb a carbon fiber wheel, the financial implications can be staggering. Basic cosmetic repairs start around $350-450, while structural damage often necessitates complete wheel replacement at costs ranging from $2,000 to $5,000 per wheel. Unlike aluminum wheels that can often be straightened or welded, carbon fiber damage frequently means starting over with a new wheel.

Immediate Effects of Curbing a Carbon Fiber Wheel

Surface-Level Cosmetic Damage

The most common and least severe outcome of curbing a carbon fiber wheel is surface-level cosmetic damage. This typically manifests as paint scuffs, clear coat damage, or minor scratches that only affect the protective outer layers. These superficial injuries don't compromise the structural integrity of the wheel but can be unsightly and may allow moisture penetration if left untreated.

Surface damage often appears as white or silver marks where the curb has scraped away the colored finish, revealing the underlying carbon fiber weave or protective coating. While alarming in appearance, this type of damage is generally the most manageable and cost-effective to repair.

Structural Integrity Concerns

More serious curb impacts can compromise the structural integrity of the wheel, even when the damage isn't immediately visible. The layered construction of carbon fiber means that surface damage may mask deeper issues within the composite structure. Internal delamination—where the layers of carbon fiber separate—can occur without obvious external signs, creating a hidden weakness that could lead to sudden failure.

Hairline Cracks and Delamination

Hairline cracks represent one of the most dangerous forms of carbon fiber wheel damage because they indicate compromised structural integrity that will likely worsen over time. These microscopic fractures can propagate through the material under normal driving stresses, potentially leading to catastrophic failure without warning.

Delamination occurs when the resin matrix holding the carbon fibers together begins to fail, causing layers to separate internally. This process can be triggered by impact damage and may continue to spread even after the initial incident, making early detection and assessment crucial for safety.

Understanding Carbon Fiber Wheel Construction

How Carbon Fiber Fails vs. Metal Wheels

The failure mechanisms of carbon fiber wheels differ dramatically from traditional metal wheels. Aluminum wheels typically bend, crack gradually, or show visible signs of distress before complete failure, giving drivers warning that something is wrong. Carbon fiber wheels, however, can maintain their appearance and basic function until reaching a critical failure point, at which time they can fail suddenly and completely.

This binary nature of carbon fiber failure—either fine or catastrophically broken—makes damage assessment particularly challenging. A wheel might appear perfectly normal while harboring internal damage that could lead to sudden failure during high-speed driving or hard cornering.

Critical Stress Points and Weak Areas

Carbon fiber wheels have specific areas that are more vulnerable to impact damage and subsequent failure. The spoke-to-rim junction areas experience high stress concentrations and are particularly susceptible to crack initiation. The outer rim edge, where the tire mounts, is another critical area that bears the brunt of curb impacts.

Heat buildup from braking can also weaken these critical areas over time, making them more susceptible to impact damage. The combination of thermal cycling and mechanical stress creates conditions where seemingly minor impacts can cause significant damage.

Spoke Holes and Junction Areas

The spoke holes and surrounding areas represent some of the highest stress concentrations in carbon fiber wheels. When a curb impact occurs, stress waves propagate through the wheel structure, often concentrating at these geometric discontinuities. Cracks that develop in or near spoke holes are particularly dangerous because they can quickly compromise the wheel's ability to transfer loads safely.

Even minor visible damage near spoke holes should be treated as potentially serious, requiring professional inspection to determine if the wheel is safe for continued use.

Types of Damage from Curb Impact

Minor Curb Rash (Cosmetic Only)

Minor curb rash affects only the surface layers of the wheel—typically the paint, clear coat, or protective finish. This type of damage looks dramatic but doesn't penetrate into the carbon fiber structure itself. The affected area might show scuff marks, color changes, or texture differences but won't exhibit cracks, delamination, or structural deformation.

Professional assessment can usually determine quickly whether damage is truly cosmetic by examining the depth of scratches and checking for any signs of underlying structural issues. Cosmetic-only damage can typically be repaired by sanding, filling, and refinishing the affected area.

Deep Gouges and Material Removal

Deep gouges that penetrate through the protective layers and into the carbon fiber weave represent a more serious concern. While not immediately dangerous, these gouges create stress concentration points that can initiate crack formation under normal loading conditions. The exposed carbon fibers are also vulnerable to moisture ingress and environmental degradation.

Repair of deep gouges requires careful assessment to determine whether the structural integrity has been compromised. Some gouges can be repaired by building up the area with new carbon fiber material and resin, but this process is complex and expensive.

Catastrophic Structural Failure

In severe curb impacts, carbon fiber wheels can experience immediate catastrophic failure, where large sections crack, break away, or completely separate from the rest of the wheel. This type of damage is unmistakable and renders the wheel immediately unsafe for any use.

Catastrophic failures often result from high-speed impacts or situations where the wheel absorbs significant energy, such as hitting a high curb or pothole at speed. The sudden nature of these failures underscores the importance of careful driving and regular inspection of carbon fiber wheels.

Heat Damage from Friction

The friction generated during a curb strike can create localized heating that damages the resin matrix in carbon fiber wheels. This thermal damage may manifest as discoloration, surface texture changes, or weakening of the bond between carbon fibers. Heat damage is particularly concerning because it can affect areas beyond the visible impact point.

Temperature-related damage may not be immediately apparent but can progressively weaken the wheel structure over time. Professional inspection using thermal imaging or other diagnostic tools may be necessary to fully assess heat-related damage.

Safety Implications and Warning Signs

When to Stop Driving Immediately

Certain types of carbon fiber wheel damage require immediate cessation of driving to prevent catastrophic failure and potential injury. Any visible cracks, especially those radiating from spoke holes or extending across the wheel face, indicate critical structural compromise. Delamination, bulging, or soft spots in the wheel structure also warrant immediate停止driving.

Unusual vibrations, noises, or handling characteristics following a curb impact should be treated as potential signs of serious damage, even if no visible damage is apparent. The safety-critical nature of wheels means that any doubt about structural integrity should err on the side of caution.

Signs of Progressive Damage

Carbon fiber wheel damage can worsen over time, even after the initial impact. Progressive damage signs include expanding cracks, increasing vibration, changes in tire wear patterns, or new noises during driving. These symptoms indicate that the initial damage is spreading through the wheel structure.

Regular inspection after any impact is crucial because carbon fiber damage doesn't always heal or stabilize—it often continues to propagate until catastrophic failure occurs. Documenting the condition of wheels with photographs immediately after an impact can help identify any changes during subsequent inspections.

Unusual Noises and Vibrations

New or unusual noises following a curb impact can indicate internal damage that isn't visible externally. Clicking, creaking, or grinding sounds that correspond to wheel rotation suggest potential structural issues within the carbon fiber matrix. Similarly, vibrations that weren't present before the impact often indicate that the wheel is no longer perfectly round or balanced.

These symptoms should prompt immediate professional inspection, as they often precede more serious structural failures. The carbon fiber construction makes it difficult to assess internal damage visually, making these audible and tactile clues particularly important for early detection.

Inspection and Assessment Guide

Professional vs. DIY Inspection

While car owners can perform basic visual inspections of their carbon fiber wheels, professional assessment is essential for determining the extent of impact damage. Professionals have access to specialized tools like ultrasonic thickness gauges, X-ray equipment, and thermal imaging systems that can detect internal damage not visible to the naked eye.

DIY inspection should focus on obvious visual cues like cracks, delamination, surface damage, and changes in wheel shape or balance. However, the critical decision of whether a wheel is safe for continued use should always involve professional expertise, given the potential safety consequences of undetected damage.

What to Look For During Inspection

Thorough inspection of a potentially damaged carbon fiber wheel should examine multiple aspects of the wheel structure. Visual inspection should look for cracks of any size, surface delamination, color changes that might indicate heat damage, and any areas where the carbon fiber weave appears disturbed.

Tactile inspection involves feeling for soft spots, raised areas, or surface irregularities that might indicate internal damage. The wheel should also be checked for roundness and balance, as impact damage can cause geometric distortion even when structural integrity appears intact.

X-ray and Ultrasonic Testing Methods

Advanced inspection techniques like X-ray imaging and ultrasonic testing can reveal internal damage that's completely invisible from external inspection. These methods are particularly valuable for carbon fiber wheels because the composite construction can hide significant internal damage behind apparently normal surfaces.

Professional wheel inspection services may employ these techniques for high-value wheels or when safety is paramount. While expensive, these inspection methods can provide definitive answers about internal structural integrity that visual inspection simply cannot achieve.

Repair Options and Costs

Cosmetic Repair Procedures

Cosmetic repairs for carbon fiber wheels typically involve sanding the damaged area, applying filler or new carbon fiber material if necessary, and refinishing with paint and clear coat to match the original appearance. These repairs can restore the wheel's appearance but don't address any underlying structural issues.

The process requires specialized knowledge of carbon fiber materials and finishing techniques to achieve acceptable results. Quality cosmetic repairs typically cost between $350-600, depending on the extent of damage and the complexity of the original finish.

Structural Repair Limitations

Structural repairs of carbon fiber wheels are extremely limited compared to metal wheel repairs. The composite nature of the material means that cracks, delamination, or other structural damage typically cannot be repaired to original strength levels. Even when repairs are technically possible, they often cost nearly as much as wheel replacement while providing uncertain long-term reliability.

Most manufacturers and safety experts recommend replacement rather than structural repair for carbon fiber wheels with anything beyond minor cosmetic damage. The safety-critical nature of wheels, combined with the unpredictable failure characteristics of repaired carbon fiber, makes replacement the conservative choice.

Professional Repair Services

Specialized shops like Spyder Composites have developed expertise in carbon fiber wheel repair, but even these professionals are limited in what they can safely accomplish. Their services typically focus on cosmetic restoration and minor structural repairs where the damage doesn't compromise critical load-bearing areas.

Professional repair services can assess whether damage is repairable and provide honest guidance about the safety implications of various repair options. However, they typically won't warranty structural repairs to the same degree as cosmetic work, reflecting the inherent limitations of carbon fiber repair technology.

Prevention Strategies

Driving Techniques and Awareness

The best strategy for dealing with carbon fiber wheel damage is prevention through careful driving techniques and heightened awareness of road hazards. This includes maintaining safe following distances to spot obstacles early, reducing speed when navigating tight parking areas, and being particularly cautious around curbs and road edges.

Drivers should develop habits of checking wheel clearance when parking and being extra cautious in unfamiliar parking environments. The high replacement costs of carbon fiber wheels justify additional caution and attention to driving situations that pose curb strike risks.

Protective Solutions

Various aftermarket products claim to provide curb protection for wheels, though their effectiveness varies significantly. Rim protectors, rubber strips, and protective films can provide some defense against minor scrapes but offer limited protection against significant impacts.

While these products may help with minor contact, they shouldn't be relied upon as complete protection against curb damage. The energy involved in most curb strikes is far beyond what simple protective devices can absorb.

Wheel Protection Products

Some wheel protection products focus on early warning systems that alert drivers when they're approaching curbs too closely. These technological solutions can be particularly valuable for expensive carbon fiber wheels where the cost of damage far exceeds the price of prevention systems.

However, the most effective protection remains driver awareness and careful technique. No aftermarket protection system can substitute for attentive driving and proper spatial awareness around curbs and obstacles.

When to Replace vs. Repair

Decision-Making Criteria

The decision between repairing and replacing a damaged carbon fiber wheel should prioritize safety above all other considerations. Any damage that compromises structural integrity—including cracks, delamination, or damage near critical areas like spoke holes—typically warrants replacement regardless of cost.

For purely cosmetic damage, the decision may come down to cost-benefit analysis and personal preferences about appearance. However, even cosmetic damage should be professionally assessed to ensure no hidden structural issues exist.

Insurance Considerations

Many automotive insurance policies cover wheel damage, though coverage varies significantly between insurers and policy types. Given the high cost of carbon fiber wheels, understanding your coverage before damage occurs can be valuable for financial planning.

Some specialty insurers offer specific coverage for high-value wheels and modifications, which may be worth considering for vehicles equipped with expensive carbon fiber wheels. Documentation of wheel value and condition can be important for insurance claims.

Cost-Benefit Analysis

When weighing repair versus replacement costs, consider not only the immediate expense but also the long-term reliability and safety implications. A $600 repair on a wheel worth $3,000 might seem attractive, but if the repair compromises safety or durability, replacement becomes the better value.

The resale value implications should also be considered, as repaired wheels may affect the overall value of the vehicle. Potential buyers are often wary of structural repairs to safety-critical components like wheels.

Conclusion: The Bottom Line on Carbon Fiber Wheel Curbing

Key Takeaways for Owners

Carbon fiber wheel damage from curb strikes represents a serious concern that goes far beyond cosmetic issues. The unique properties of carbon fiber—high strength but brittle failure characteristics—mean that seemingly minor damage can hide serious structural problems that could lead to catastrophic failure.

The high cost of carbon fiber wheels makes prevention through careful driving practices the most cost-effective approach. When damage does occur, professional assessment is essential to determine whether the wheel remains safe for use or requires replacement.

Final Recommendations

For carbon fiber wheel owners, the best approach combines prevention through careful driving, immediate professional assessment after any impact, and conservative decision-making about repairs versus replacement. The safety implications of wheel failure far outweigh the cost considerations in most situations.

Consider carbon fiber wheels as precision instruments that require careful handling and professional attention when damaged. While expensive, this approach ensures both safety and optimal performance from these advanced automotive components. Remember that with carbon fiber wheels from quality manufacturers like those available through AME Motorsport, proper care and handling can provide years of exceptional performance and aesthetic appeal.

The investment in carbon fiber wheel technology brings significant performance benefits, but it comes with the responsibility of understanding and respecting the unique characteristics of these advanced materials. By following proper care, inspection, and repair protocols, owners can maximize both the performance and safety benefits of their carbon fiber wheel investment.