What is a Cat-Back Exhaust? The Complete Guide to Performance and Sound Enhancement

Cat-back exhaust systems represent one of the most popular and effective modifications for enhancing vehicle performance, sound, and efficiency. These comprehensive systems replace everything from the catalytic converter to the exhaust tips, providing substantial improvements while maintaining emissions compliance and street legality.

Understanding Cat-Back Exhaust Systems

Definition and Basic Components

A cat-back exhaust system refers to all the exhaust components located "back" from the catalytic converter ("cat") to the rear of the vehicle. This comprehensive system typically includes the mid-pipe that connects to the catalytic converter, the muffler, resonator (if equipped), tailpipes, and exhaust tips. The term "cat-back" specifically indicates that the catalytic converter remains untouched, which has significant implications for emissions compliance and legal requirements.

When you install a cat-back exhaust system, you're essentially replacing everything from the catalytic converter outlet to where the exhaust exits your vehicle. This comprehensive replacement allows manufacturers to optimize the entire exhaust flow path for better performance and sound characteristics. The system works as an integrated unit, with each component designed to complement the others for maximum effectiveness.

The beauty of cat-back systems lies in their ability to dramatically improve your vehicle's exhaust flow without compromising emissions equipment. Since the catalytic converter processes harmful emissions before they reach the cat-back system, you can enjoy enhanced performance while remaining environmentally responsible and legally compliant.

The Science Behind Cat-Back Design

Modern cat-back exhaust systems are engineered using advanced fluid dynamics principles to optimize exhaust gas flow. The primary goal is to reduce backpressure – the resistance that exhaust gases encounter as they travel through the system. When backpressure is minimized, your engine can expel exhaust gases more efficiently, allowing it to breathe better and produce more power.

Engineers design cat-back systems with larger diameter pipes than stock systems, typically ranging from 2.5 to 3 inches in diameter depending on the vehicle. However, pipe diameter must be carefully calculated because pipes that are too large can actually decrease performance by reducing exhaust gas velocity. This is why professional manufacturers spend considerable time testing and tuning their systems for specific vehicle applications.

Mandrel bending is another crucial technology used in quality cat-back systems. Unlike crush bending used in many stock systems, mandrel bending maintains consistent pipe diameter throughout turns and curves. This consistency ensures smooth exhaust flow without restriction points that can create turbulence and reduce performance.

How Cat-Back Systems Differ from Stock Exhausts

Manufacturing and Design Philosophy

Factory exhaust systems are typically designed with multiple priorities that often conflict with pure performance. Manufacturers must balance cost constraints, noise regulations, emissions compliance, and space limitations while producing systems that will last the vehicle's warranty period. This results in compromises that leave significant performance potential on the table.

Stock exhaust systems commonly use smaller diameter pipes, typically 2 to 2.25 inches, compared to the 2.5 to 3+ inch pipes found in performance cat-back systems. The smaller pipes create more restriction, limiting exhaust flow and reducing power output. Additionally, factory systems often use crush-bent pipes that create flow restrictions at every bend point.

Factory mufflers are specifically designed to minimize noise, often at the expense of flow efficiency. Aftermarket cat-back systems use performance-oriented mufflers that balance sound control with optimal flow characteristics. This allows for a more aggressive, sporty sound while actually improving exhaust flow compared to restrictive stock mufflers.

Material Quality Differences

Materials represent another significant difference between stock and aftermarket cat-back systems. While many factory systems use basic aluminized steel that can rust and deteriorate over time, quality cat-back systems typically use 304 or 409 stainless steel that resists corrosion and maintains performance characteristics longer.

Components and Construction of Cat-Back Systems

Mid-Pipe and Resonator Functions

The mid-pipe serves as the crucial link between your vehicle's catalytic converter and the rear exhaust components. This section of the cat-back system is often overlooked, but it plays a vital role in determining both performance characteristics and sound quality. Quality cat-back systems feature mid-pipes with optimized diameter and length to maintain proper exhaust gas velocity while minimizing restrictions.

In many performance cat-back systems, the mid-pipe incorporates an X-pipe or H-pipe design for dual exhaust applications. These configurations allow exhaust pulses from different engine cylinders to interact and balance, creating more efficient exhaust evacuation and often producing a more pleasing sound signature. The design choice between X-pipe and H-pipe configurations affects both performance and sound characteristics, with X-pipes typically producing higher-pitched notes and H-pipes creating deeper tones.

Resonators within the mid-pipe section serve a sophisticated acoustic engineering function. Unlike simple mufflers, resonators are tuned to specific frequencies to cancel out unwanted drone and harsh tones while preserving desirable exhaust notes. This selective sound filtering allows cat-back systems to produce aggressive performance sounds without the annoying drone that can make highway driving uncomfortable.

Material Choices: Stainless Steel vs. Aluminized Steel

The choice of construction materials represents one of the most important decisions when selecting a cat-back exhaust system. This choice affects durability, performance, weight, cost, and long-term maintenance requirements.

304 Stainless Steel represents the premium choice for cat-back exhaust construction. This aerospace-grade material offers exceptional corrosion resistance, maintaining performance and appearance even in harsh environments. Stainless steel systems typically last significantly longer than alternatives and maintain their flow characteristics over time without internal corrosion restricting performance. The biggest advantage of stainless steel is its exceptional resistance to rust and corrosion. Unlike mild steel or aluminized steel, stainless steel contains chromium, which forms a protective oxide layer that prevents oxidation.

409 Stainless Steel provides a more affordable alternative that still offers good corrosion resistance. While not as corrosion-resistant as 304 stainless, 409 stainless steel offers a good balance of durability and cost for many applications. Many quality cat-back systems use 409 stainless steel to achieve better pricing while still providing superior longevity compared to aluminized alternatives. T409 has a chromium content of 10.50% to 11.75% while its nickel content is only 0.50%.

Aluminized Steel represents the most economical option for cat-back construction. While less expensive, aluminized steel systems may not last as long in corrosive environments and can experience internal scaling that reduces flow over time. However, for budget-conscious enthusiasts or vehicles in mild climates, quality aluminized steel systems can provide good performance at attractive pricing.

Performance Benefits of Cat-Back Exhaust Systems

Horsepower and Torque Improvements

One of the primary motivations for installing a cat-back exhaust system is the potential for measurable horsepower and torque gains. These improvements result from reducing exhaust backpressure and allowing the engine to operate more efficiently throughout its RPM range. While gains vary significantly based on the specific vehicle and system design, most properly designed cat-back systems provide noticeable performance improvements.

Typical horsepower gains from cat-back exhaust systems range from 5 to 15 horsepower at the wheels, depending on the vehicle's factory exhaust restrictions and engine characteristics. Naturally aspirated engines often see more dramatic improvements because they rely entirely on atmospheric pressure for intake airflow, making exhaust efficiency more critical. Turbocharged engines may see smaller gains from cat-back systems alone but can benefit significantly when combined with other modifications.

Torque improvements are often more noticeable than raw horsepower gains, particularly in the mid-range RPM where most daily driving occurs. Enhanced exhaust flow improves engine breathing efficiency, allowing for better cylinder filling and more complete combustion. This translates to improved throttle response and better pulling power for real-world driving situations.

Enhanced Exhaust Flow and Reduced Backpressure

Understanding backpressure reduction is crucial to appreciating how cat-back exhaust systems improve performance. Backpressure represents the resistance that exhaust gases encounter as they travel through the exhaust system. High backpressure forces the engine to work harder to expel exhaust gases, reducing power output and efficiency.

Factory exhaust systems often incorporate significant backpressure due to small pipe diameters, restrictive mufflers, and crush-bent piping. These restrictions may help reduce noise and manufacturing costs, but they limit engine performance potential. Cat-back systems address these restrictions through larger diameter pipes, performance-oriented mufflers, and mandrel-bent construction.

Flow efficiency improvements from cat-back systems benefit engine operation in multiple ways. Better exhaust evacuation allows for improved intake airflow, creating a more efficient combustion cycle. This improved breathing can enhance fuel atomization and combustion efficiency, contributing to both performance and fuel economy improvements.

Fuel Economy Considerations

Many cat-back exhaust system owners report improved fuel economy, particularly during highway driving. These improvements result from the engine operating more efficiently when exhaust backpressure is reduced. However, fuel economy changes depend heavily on driving habits and the specific vehicle application.

Highway fuel economy improvements of 1-3 MPG are commonly reported with quality cat-back systems. The improvements are most noticeable during steady-state cruising where the engine benefits from reduced pumping losses. City driving may show less dramatic improvements because frequent acceleration and deceleration patterns don't allow the efficiency gains to fully manifest.

Engine load reduction contributes to fuel economy improvements when cat-back systems are properly designed. Reduced exhaust backpressure means the engine doesn't work as hard to expel exhaust gases, allowing more energy to be transmitted to the wheels rather than being consumed by exhaust system resistance. This is particularly beneficial for vehicles that frequently operate under load, such as those used for towing.

Sound Enhancement and Acoustic Engineering

Creating the Perfect Exhaust Note

Cat-back exhaust systems provide substantial sound enhancement compared to restrictive factory systems. Whether you want just a little more grunt or a full-on growl, there is a cat-back exhaust system out there that will satisfy your ears. This is actually a very big consideration when purchasing a cat-back exhaust, so make sure to do your homework first.

Cat-back systems typically provide a more aggressive and pronounced exhaust note without being overly loud. This can give your vehicle a sportier sound. The sound characteristics depend heavily on the muffler design and internal construction. Chambered mufflers use internal walls to redirect exhaust flow, creating backpressure but effectively reducing noise. They're good for quietness and retaining low-RPM torque.

Straight-through mufflers feature a perforated pipe running straight through a casing packed with sound-absorbing material like fiberglass. These offer minimal restriction, favoring high-RPM power, but are typically louder. Variable valve exhaust systems combine both concepts, using a valve controlled electronically or by vacuum to divert exhaust gases through either a quiet, chambered path or a loud, straight-through path.

Managing Drone and Unwanted Frequencies

The strategic placement of resonators and mufflers within the system plays a vital role in performance optimization. These components are designed not just for sound control, but also to maintain proper exhaust pulse timing and scavenging effects that can actually enhance engine performance, particularly in high-performance applications.

Professional cat-back system manufacturers design drone-free, aggressive mufflers tuned specifically for different engine configurations. The Redline series, for example, is designed to get the most aggressive sound out of your ride while maximizing the volume and tone of the engine, while still eliminating any drone in the cabin.

Cat-Back vs. Other Exhaust Systems

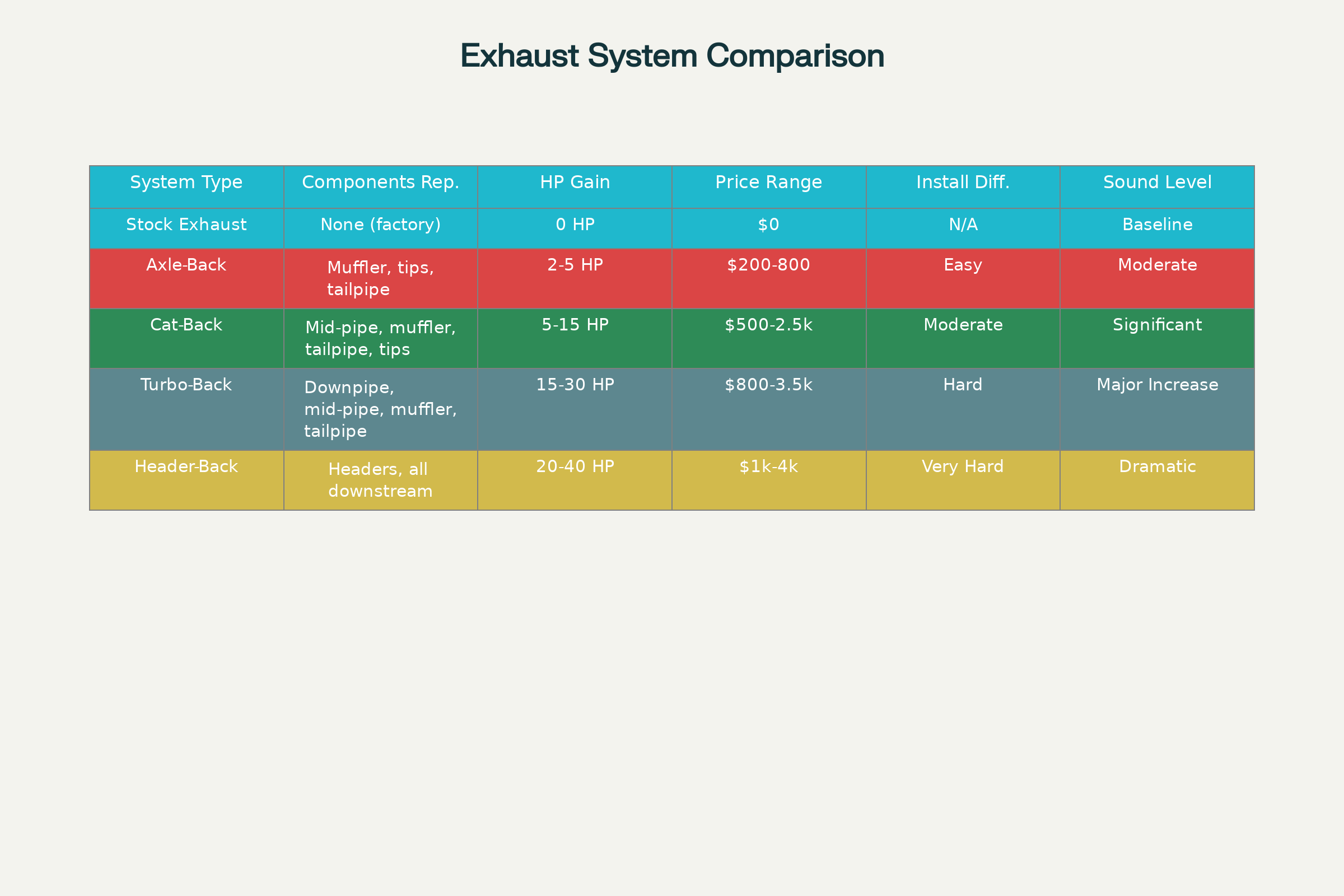

The comparison table above illustrates the key differences between various exhaust system types. Cat-back systems offer an excellent balance of performance gains, reasonable pricing, and moderate installation difficulty, making them the most popular choice among enthusiasts.

Cat-Back vs. Axle-Back Systems

Axle-back exhaust systems include only the parts after the rear axle of a vehicle, which usually consists of the muffler, tailpipe and tips. While axle-back systems are less expensive and easier to install, they provide limited performance gains compared to cat-back systems.

Cat-back systems typically yield more performance benefits than an axle-back exhaust due to their larger diameter, mandrel-bent tubing and inclusion of the mid-pipe section. For those looking to not only increase sound and volume but performance as well, the cat-back is the best option.

Cat-Back vs. Turbo-Back Systems

Turbo-back exhaust systems replace the entire exhaust system from the turbocharger to the exhaust tip. These systems deliver more significant power and torque gains than cat-back systems due to their comprehensive approach to exhaust flow improvements. However, turbo-back systems are significantly more expensive and complex to install.

A turbo-back exhaust is going to make more power than a cat-back exhaust but will cost significantly more because you're replacing the full exhaust system. Turbo-back systems are primarily designed for turbocharged vehicles where the downpipe represents a major restriction point.

Installation Process and Requirements

Tools and Preparation

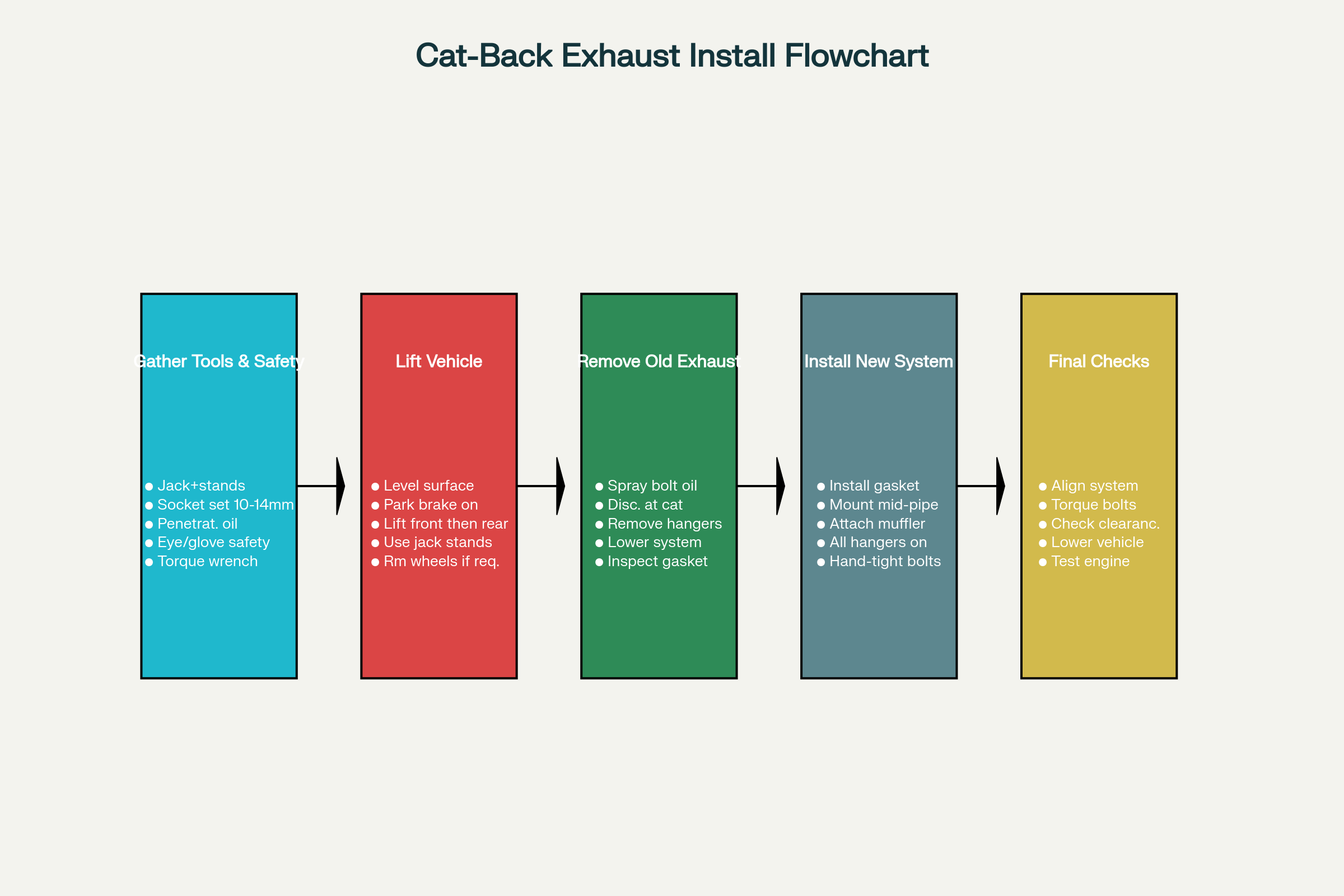

Installing a cat-back exhaust system requires specific tools and safety equipment. Commonly required tools include a jack and jack stands, a wrench set, socket set (10mm, 12mm, 14mm), Allen wrenches, a torque wrench, and penetrating oil. Additionally, it's essential to have safety gear such as gloves and eye protection.

Before starting the installation, make sure you have all the necessary tools at hand. Park your vehicle on a flat surface and engage the parking brake. Use a jack to lift the vehicle off the ground, one corner at a time, and secure it in place with jack stands. Ensure the vehicle is stable and won't move during the installation process.

Step-by-Step Installation Process

The installation process generally follows these main steps:

-

Preparation and Safety: Set parking brake, put car in neutral or park, raise and support rear of car using jack stands, and put on protective eyewear.

-

Remove Old System: Give the nuts holding the exhaust onto the cat a good squirt of penetrating oil and let it soak in. Undo the hangers that are held on by bolts, then remove the earthing wire and pull the exhaust away from the cat.

-

Install New Components: Take the rubber hangers off the old exhaust and transfer them to the new exhaust. Attach the new exhaust to the catalytic converter using a new gasket and silicon sealant.

-

Final Assembly: Mount the rear section of the exhaust, attach all hangers, and hand-tighten all bolts. Make sure the tailpipe and exhaust system are fitted the way you want before fully tightening.

-

Final Checks: Once everything is aligned properly, tighten all U-bolts and flange bolts to specification. Lower the car and fire up the engine to test the installation.

Professional vs. DIY Installation

Cat-back systems are usually designed to bolt directly to your existing exhaust components, making installation relatively straightforward for those with moderate mechanical skills. The systems are designed for straightforward installation, often requiring minimal tools and time.

However, if you're not confident in performing the installation yourself, it's always best to seek professional help. Professional installation ensures proper fitment, alignment, and torque specifications, which are crucial for optimal performance and longevity of the system.

Legal Considerations and Emissions Compliance

Federal and State Regulations

For those concerned about legal compliance, rest assured that most cat-back systems meet necessary regulations without modifying stock catalytic converters. The catalytic converter must stay unmodified since cat-back systems need all emissions equipment intact.

In the U.S., the legal status of cat-back exhaust systems varies by state and federal regulations. On the federal level, the Environmental Protection Agency (EPA) sets guidelines for vehicle emissions, and modifying exhaust systems to bypass emissions control devices, such as catalytic converters, is illegal. However, since cat-back systems retain the catalytic converter, they are generally legal in most states.

Noise Regulations and Testing

Florida sets strict legal limits on exhaust noise - 82 dBA for motorcycles and 90 dBA for larger vehicles. California has some of the strictest emissions and noise laws in the country. Under California's Vehicle Code, any exhaust modification that bypasses the catalytic converter is prohibited. Even modifications that only affect noise levels can lead to fines or penalties if they exceed the state's decibel limits.

It's important to check local regulations before making any exhaust modifications, as some states may be more lenient than others. Police typically look at exhaust modifications before writing citations, so ensuring your system meets local noise requirements is crucial.

Maintaining Emissions Compliance

Since the catalytic converter is not modified or removed in cat-back systems, emissions compliance is maintained. This makes cat-back systems one of the most popular exhaust upgrades because they provide substantial performance benefits while maintaining street legality in most jurisdictions.

The system works to maintain emissions compliance because the catalytic converter processes harmful emissions before they reach the cat-back system. This allows you to enjoy enhanced performance while remaining environmentally responsible and legally compliant.

Maintenance and Care

Regular Inspection and Cleaning

Cat-back exhaust systems require very little care and maintenance. Regular inspections by a qualified specialist are essential in identifying any potential issues. By scheduling routine maintenance, you can catch minor problems early on and prevent them from becoming major and costly repairs.

You should check the exhaust system a minimum of once a year. Problems will often present themselves visually before they start affecting performance, so this is a good way to catch them early. Look for rust and corrosion, holes, cracks, dents and loose parts, incorrectly aligned pipes, broken clamp connections, and burned gaskets and seals.

Cleaning and Protection

Use mild car soap to clean the exhaust system—do not use any abrasives or degreasers. Clean your exhaust with metal/stainless polish every 1-2 months to retain the luster and remove dirt and grime. After looking the system over, you should give it a good cleaning, as the build-up of dirt, grease, grime and carbon deposits will affect exhaust flow and heat levels.

Regularly cleaning your muffler and exhaust pipes can help remove dirt, debris, and road salt, preventing corrosion and rust formation. Additionally, applying a high-temperature-resistant paint or rust inhibitor can further protect the components.

Environmental Considerations

If you ride in coastal regions or areas that use salt to control ice and snow, wipe the exhaust down after it cools to remove any possible salt residue, which can result in rusting. Keep it clean: Salt, dirt, and moisture can lead to rust and corrosion. If you live in an area that uses road salt, regularly wash the underside of your vehicle to remove these corrosive agents.

Avoid excessive idling, as this can overheat and stress the components. Moderate your speed when going over speed bumps or rough road surfaces to prevent unnecessary strain on the system. Limiting exposure to extreme driving conditions, such as off-roading or deep snow, can also help reduce the risk of damage.

Choosing the Right Cat-Back System

Vehicle-Specific Considerations

When selecting a cat-back exhaust system, it's crucial to choose one that fits your vehicle's exact specifications. The cat-back exhaust should have sufficient room with the catalytic converter and other components. You can explore cat-back systems to find the best fit for your car's model and year.

Small, naturally aspirated engines are very sensitive to losing backpressure and may not benefit much from extensive exhaust modifications for street use. Turbocharged engines generally respond very well to reduced backpressure, especially post-turbo. Consider your car's specific engine characteristics when making your selection.

Brand Selection and Quality

There are lots of exhaust manufacturers out there, but some of the most popular are Flowmaster, Magnaflow, Gibson, Banks, Corsa and Borla. Choose reputable brands and types: Established manufacturers invest in R&D and testing. For a balance of sound and performance without sacrificing too much drivability, consider high-quality systems or variable valve exhausts.

Look for stainless steel or aluminized steel exhausts. Stainless steel offers the best durability and corrosion resistance, ideal for harsh climates. Ensure the exhaust pipes are mandrel-bent, which maintains a consistent diameter throughout bends, reducing restriction and improving flow.

Sound Preferences and Performance Goals

Define your goals: Are you after sound, better street drivability, maximum track power, or a balance? What's your driving style? Different muffler designs will produce vastly different sound characteristics, so research is essential before making a purchase.

Chambered/baffled mufflers are similar to many stock mufflers, using internal walls to redirect exhaust flow, creating backpressure but effectively reducing noise. They're good for quietness and retaining low-RPM torque. Straight-through/absorption mufflers feature a perforated pipe running straight through a casing packed with sound-absorbing material, offering minimal restriction but typically being louder.

Cost Considerations and Value

Initial Investment

Cat-back systems tend to be more expensive than axle-back options due to the inclusion of additional components. Cat-back exhaust systems typically range from $500-2500 depending on the vehicle application, materials used, and brand reputation. The price difference is really the biggest part when comparing to simpler systems.

Premium materials like 304 stainless steel will command higher prices but offer superior longevity and performance retention. While the initial investment may be higher, the long-term value proposition often favors quality cat-back systems due to their durability and performance benefits.

Long-Term Value

When properly selected and installed, cat-back exhaust systems provide excellent long-term value through improved performance, enhanced sound, and increased fuel efficiency. The combination of power gains, sound enhancement, and potential fuel economy improvements can provide tangible benefits that justify the initial investment.

Quality stainless steel systems can last the lifetime of the vehicle when properly maintained, making them a worthwhile investment for serious enthusiasts. The resale value benefits and enhanced driving experience further contribute to the overall value proposition.

Common Misconceptions and Myths

Performance Myths

One common myth is that bigger exhaust pipes are always better and that lower backpressure is always superior. In reality, exhaust pipe diameter needs to be matched to the engine's displacement and intended RPM range. Pipes that are too large can decrease exhaust gas velocity at lower RPMs, hurting scavenging and reducing low-end torque.

Another misconception is that modifying the exhaust always means losing low-end torque and always increases horsepower. It depends entirely on the modification. Well-designed systems, including properly sized pipes and components, can improve power across a broader range, sometimes even improving low-end response slightly.

Legal and Emissions Myths

Some people believe that any exhaust modification will cause emissions compliance issues. However, cat-back systems specifically retain all emissions equipment, including the catalytic converter, making them legal in most jurisdictions. The key is ensuring that no emissions control devices are removed or bypassed.

Another myth is that louder exhausts are automatically illegal. While noise regulations do exist, properly designed cat-back systems can provide enhanced sound while staying within legal decibel limits. The key is choosing systems from reputable manufacturers who design their products to meet applicable regulations.

Future Trends and Technology

Advanced Materials and Manufacturing

The exhaust industry continues to evolve with advances in materials science and manufacturing techniques. New alloy compositions and treatments are being developed to provide even better corrosion resistance and heat handling capabilities. Advanced manufacturing processes like hydroforming and computer-controlled mandrel bending are becoming more common, allowing for more complex and efficient designs.

Electronic Integration

Variable valve exhaust systems are becoming increasingly popular, allowing drivers to switch between quiet and aggressive modes electronically. These systems combine the benefits of both chambered and straight-through designs, offering versatility for different driving conditions. Integration with vehicle computer systems allows for automatic sound management based on driving mode, time of day, or location.

Environmental Considerations

As emissions regulations continue to tighten globally, exhaust manufacturers are focusing on designs that maximize performance while maintaining or improving emissions characteristics. Advanced catalytic converter integration and improved flow dynamics are helping achieve both performance and environmental goals simultaneously.

Cat-back exhaust systems represent an excellent entry point into performance modifications, offering substantial benefits in power, sound, and efficiency while maintaining emissions compliance and reasonable installation complexity. Whether you're seeking improved performance, enhanced sound, or better fuel economy, a properly selected cat-back system can transform your driving experience while keeping you on the right side of the law. The key to success lies in choosing quality components from reputable manufacturers, ensuring proper installation, and maintaining the system according to manufacturer recommendations.