¿Qué es un Escape Catback? La Guía Definitiva de Rendimiento para Entusiastas del Automóvil

¿Qué es un Sistema de Escape Catback? La Guía Definitiva de Rendimiento para Entusiastas del Automóvil

Actualizar el sistema de escape de tu vehículo es una de las modificaciones más populares y efectivas que puedes hacer para mejorar tanto el rendimiento como el sonido. Entre las diversas opciones de mejora del escape disponibles, los sistemas de escape catback se destacan como el equilibrio perfecto entre ganancias de rendimiento, cumplimiento legal y rentabilidad. Si estás considerando esta modificación pero no estás seguro de lo que implica, has llegado al lugar correcto.

Comprendiendo los Sistemas de Escape Catback

Definición y Componentes Básicos

Un sistema de escape catback se refiere a todos los componentes del escape ubicados "después" del convertidor catalítico ("cat") hasta la parte trasera del vehículo. Este sistema integral típicamente incluye el tubo intermedio que se conecta al convertidor catalítico, el silenciador, el resonador (si está equipado), los tubos de cola y las puntas de escape. Comprender esta definición es crucial porque distingue a los sistemas catback de otras modificaciones del escape como los sistemas axle-back o header-back.

El término "catback" indica específicamente que el convertidor catalítico permanece intacto, lo que tiene implicaciones significativas para el cumplimiento de emisiones y los requisitos legales. Esta elección de diseño hace que los sistemas catback sean una de las mejoras de escape más populares porque proporcionan beneficios sustanciales de rendimiento mientras mantienen la legalidad en la calle en la mayoría de las jurisdicciones.

Cuando instalas un sistema de escape catback, esencialmente estás reemplazando todo desde la salida del convertidor catalítico hasta donde el escape sale de tu vehículo. Este reemplazo integral permite a los fabricantes optimizar toda la ruta del flujo de escape para obtener mejores características de rendimiento y sonido. El sistema funciona como una unidad integrada, con cada componente diseñado para complementar a los demás para una máxima efectividad.

La belleza de los sistemas catback radica en su capacidad para mejorar dramáticamente el flujo de escape de tu vehículo sin comprometer el equipo de emisiones. Dado que el convertidor catalítico procesa las emisiones dañinas antes de que lleguen al sistema catback, puedes disfrutar de un rendimiento mejorado mientras sigues siendo ambientalmente responsable y legalmente conforme.

La Ciencia Detrás del Diseño Catback

Los sistemas de escape catback modernos están diseñados utilizando principios avanzados de dinámica de fluidos para optimizar el flujo de gases de escape. El objetivo principal es reducir la contrapresión (backpressure) – la resistencia que encuentran los gases de escape a medida que viajan a través del sistema. Cuando se minimiza la contrapresión, tu motor puede expulsar los gases de escape de manera más eficiente, permitiéndole respirar mejor y producir más potencia.

Los ingenieros diseñan sistemas catback con tubos de mayor diámetro que los sistemas de serie, típicamente que van desde 2.5 a 3 pulgadas de diámetro dependiendo del vehículo. Sin embargo, el diámetro del tubo debe calcularse cuidadosamente porque los tubos que son demasiado grandes en realidad pueden disminuir el rendimiento al reducir la velocidad del gas de escape. Es por eso que los fabricantes profesionales dedican un tiempo considerable a probar y ajustar sus sistemas para aplicaciones específicas de vehículos.

El doblado por mandril (mandrel bending) es otra tecnología crucial utilizada en sistemas catback de calidad. A diferencia del doblado por aplastamiento utilizado en muchos sistemas de serie, el doblado por mandril mantiene un diámetro de tubo consistente a lo largo de las curvas. Esta consistencia asegura un flujo de escape suave sin puntos de restricción que puedan crear turbulencia y reducir el rendimiento.

La ubicación estratégica de resonadores y silenciadores dentro del sistema también juega un papel vital en la optimización del rendimiento. Estos componentes están diseñados no solo para el control del sonido, sino también para mantener el tiempo adecuado de los pulsos de escape y los efectos de barrido que en realidad pueden mejorar el rendimiento del motor, particularmente en aplicaciones de alto rendimiento.

Cómo se Diferencian los Sistemas Catback de los Escapes de Serie

Los sistemas de escape de fábrica están típicamente diseñados con múltiples prioridades que a menudo entran en conflicto con el rendimiento puro. Los fabricantes deben equilibrar restricciones de costos, regulaciones de ruido, cumplimiento de emisiones y limitaciones de espacio mientras producen sistemas que durarán el período de garantía del vehículo. Esto resulta en compromisos que dejan un potencial de rendimiento significativo sobre la mesa.

Los sistemas de escape de serie comúnmente usan tubos de menor diámetro, típicamente de 2 a 2.25 pulgadas, en comparación con los tubos de 2.5 a 3+ pulgadas que se encuentran en los sistemas catback de rendimiento. Los tubos más pequeños crean más restricción, limitando el flujo de escape y reduciendo la potencia de salida. Además, los sistemas de fábrica a menudo usan tubos doblados por aplastamiento que crean restricciones de flujo en cada punto de curvatura.

Los materiales representan otra diferencia significativa entre los sistemas de escape de serie y los sistemas catback del mercado de accesorios. Mientras que muchos sistemas de fábrica usan acero aluminizado básico que puede oxidarse y deteriorarse con el tiempo, los sistemas catback de calidad típicamente usan acero inoxidable 304 o 409 que resiste la corrosión y mantiene las características de rendimiento por más tiempo.

Los silenciadores de fábrica están específicamente diseñados para minimizar el ruido, a menudo a expensas de la eficiencia del flujo. Los sistemas catback del mercado de accesorios usan silenciadores orientados al rendimiento que equilibran el control del sonido con características de flujo óptimas. Esto permite un sonido más agresivo y deportivo mientras que en realidad mejora el flujo de escape en comparación con los silenciadores de serie restrictivos.

Componentes y Construcción de los Sistemas Catback

Funciones del Tubo Intermedio y el Resonador

El tubo intermedio (mid-pipe) sirve como el enlace crucial entre el convertidor catalítico de tu vehículo y los componentes traseros del escape. Esta sección del sistema catback a menudo se pasa por alto, pero juega un papel vital en la determinación tanto de las características de rendimiento como de la calidad del sonido. Los sistemas catback de calidad presentan tubos intermedios con diámetro y longitud optimizados para mantener la velocidad adecuada del gas de escape mientras minimizan las restricciones.

En muchos sistemas catback de rendimiento, el tubo intermedio incorpora un diseño de tubo en X (X-pipe) o tubo en H (H-pipe) para aplicaciones de escape dual. Estas configuraciones permiten que los pulsos de escape de diferentes cilindros del motor interactúen y se equilibren, creando una evacuación de escape más eficiente y a menudo produciendo una firma de sonido más agradable. La elección de diseño entre las configuraciones de tubo en X y tubo en H afecta tanto las características de rendimiento como las de sonido, con los tubos en X típicamente produciendo notas más agudas y los tubos en H creando tonos más profundos.

Los resonadores dentro de la sección del tubo intermedio cumplen una función sofisticada de ingeniería acústica. A diferencia de los silenciadores simples, los resonadores están sintonizados a frecuencias específicas para cancelar el zumbido no deseado y los tonos ásperos mientras preservan las notas de escape deseables. Este filtrado de sonido selectivo permite que los sistemas catback produzcan sonidos de rendimiento agresivos sin el zumbido molesto que puede hacer incómoda la conducción en carretera.

La calidad de construcción de los componentes del tubo intermedio impacta significativamente en la durabilidad y el rendimiento del sistema. Los sistemas catback premium utilizan tubería doblada por mandril con curvas de radio suave y soldaduras de alta calidad para garantizar características de flujo consistentes y confiabilidad a largo plazo. El tubo intermedio también debe acomodar la expansión térmica y el movimiento del vehículo a través de juntas flexibles o puntos de montaje estratégicos.

Tipos y Tecnologías de Silenciadores

Los sistemas de escape catback modernos emplean varias tecnologías de silenciadores, cada una con características de rendimiento y sonido distintas. Comprender estas diferencias te ayuda a elegir un sistema que coincida con tus preferencias y uso previsto. Los tipos más comunes incluyen silenciadores con cámaras, silenciadores de flujo recto y diseños híbridos que combinan elementos de ambos enfoques.

Los silenciadores con cámaras, popularizados por marcas como Flowmaster, usan cámaras internas y deflectores para controlar el sonido mientras mantienen características de flujo razonables. Estos silenciadores crean el clásico rugido de los muscle cars americanos que muchos entusiastas prefieren. El diseño de cámara reduce efectivamente los niveles de ruido mientras produce un tono agresivo distintivo, particularmente al ralentí y a bajas RPM.

Los silenciadores de flujo recto, a menudo llamados diseños "glass pack", priorizan el flujo máximo con una restricción mínima. Estos silenciadores usan tubos perforados envueltos en material absorbente de sonido para reducir el ruido mientras mantienen excelentes características de flujo. Marcas como Borla han perfeccionado esta tecnología, creando silenciadores que producen sonidos agresivos refinados sin volumen excesivo o zumbido.

Las tecnologías de silenciadores híbridos representan el último avance en ingeniería de escape. Estos diseños combinan elementos de los enfoques con cámaras y de flujo directo para optimizar tanto el rendimiento como la calidad del sonido. Algunos incorporan válvulas ajustables que permiten a los conductores cambiar entre modos silencioso y agresivo, ofreciendo versatilidad para diferentes situaciones de conducción.

Puntas de Escape y Tubos de Cola

Aunque a menudo se consideran principalmente estéticas, las puntas de escape y los tubos de cola en realidad influyen tanto en el rendimiento como en las características de sonido de los sistemas catback. El diámetro, la longitud y el diseño interno de estos componentes afectan la velocidad de salida de los gases de escape y pueden alterar sutilmente la firma acústica del sistema.

Las puntas de escape de mayor diámetro, típicamente de 3.5 a 5 pulgadas, no solo proporcionan una apariencia agresiva, sino que también ayudan a que los gases de escape se expandan y salgan de manera más eficiente. Sin embargo, las puntas que son demasiado grandes en relación con el diámetro de la tubería del sistema pueden crear turbulencia y reducir el rendimiento. Los sistemas catback de calidad emparejan cuidadosamente el diámetro de la punta con el diseño general del sistema para obtener resultados óptimos.

Los materiales de construcción de las puntas y los acabados afectan tanto la apariencia como la durabilidad. Las puntas de acero inoxidable resisten la decoloración y la corrosión mejor que las alternativas cromadas, manteniendo su apariencia por más tiempo. Algunos sistemas premium ofrecen puntas de titanio que proporcionan la máxima reducción de peso y resistencia al calor, aunque a un costo significativamente mayor.

El diseño interno de la punta varía significativamente entre fabricantes y afecta las características del sonido. Las puntas de corte recto producen el sonido más agresivo, mientras que los cortes en ángulo o biselados pueden suavizar ligeramente la nota del escape. Algunas puntas incorporan cámaras de resonancia internas o perforaciones para afinar la salida de sonido sin afectar el rendimiento del flujo.

Opciones de Materiales: Acero Inoxidable vs. Acero Aluminizado

La elección de los materiales de construcción representa una de las decisiones más importantes al seleccionar un sistema de escape catback. Esta elección afecta la durabilidad, el rendimiento, el peso, el costo y los requisitos de mantenimiento a largo plazo. Comprender las compensaciones entre los diferentes materiales le ayuda a tomar una decisión informada basada en sus necesidades específicas y presupuesto.

El Acero Inoxidable 304 representa la opción premium para la construcción de escapes catback. Este material de grado aeroespacial ofrece una resistencia excepcional a la corrosión, manteniendo el rendimiento y la apariencia incluso en entornos hostiles. Los sistemas de acero inoxidable suelen durar significativamente más que las alternativas y mantienen sus características de flujo con el tiempo sin que la corrosión interna restrinja el rendimiento.

El Acero Inoxidable 409 proporciona una alternativa más asequible que aún ofrece buena resistencia a la corrosión. Aunque no es tan resistente a la corrosión como el acero inoxidable 304, el acero inoxidable 409 ofrece un buen equilibrio entre durabilidad y costo para muchas aplicaciones. Muchos sistemas catback de calidad utilizan acero inoxidable 409 para lograr mejores precios mientras aún proporcionan una longevidad superior en comparación con las alternativas aluminizadas.

El Acero Aluminizado representa la opción más económica para la construcción catback. Aunque menos costoso, los sistemas de acero aluminizado pueden no durar tanto en entornos corrosivos y pueden experimentar incrustaciones internas que reducen el flujo con el tiempo. Sin embargo, para entusiastas con presupuesto limitado o vehículos en climas suaves, los sistemas de acero aluminizado de calidad pueden proporcionar un buen rendimiento a precios atractivos.

Beneficios y Ventajas de Rendimiento

Mejoras en Caballos de Fuerza y Par Motor

Una de las motivaciones principales para instalar un sistema de escape catback es el potencial de ganancias medibles en caballos de fuerza y par motor. Estas mejoras resultan de reducir la contrapresión del escape y permitir que el motor opere de manera más eficiente en todo su rango de RPM. Aunque las ganancias varían significativamente según el vehículo específico y el diseño del sistema, la mayoría de los sistemas catback correctamente diseñados proporcionan mejoras de rendimiento notables.

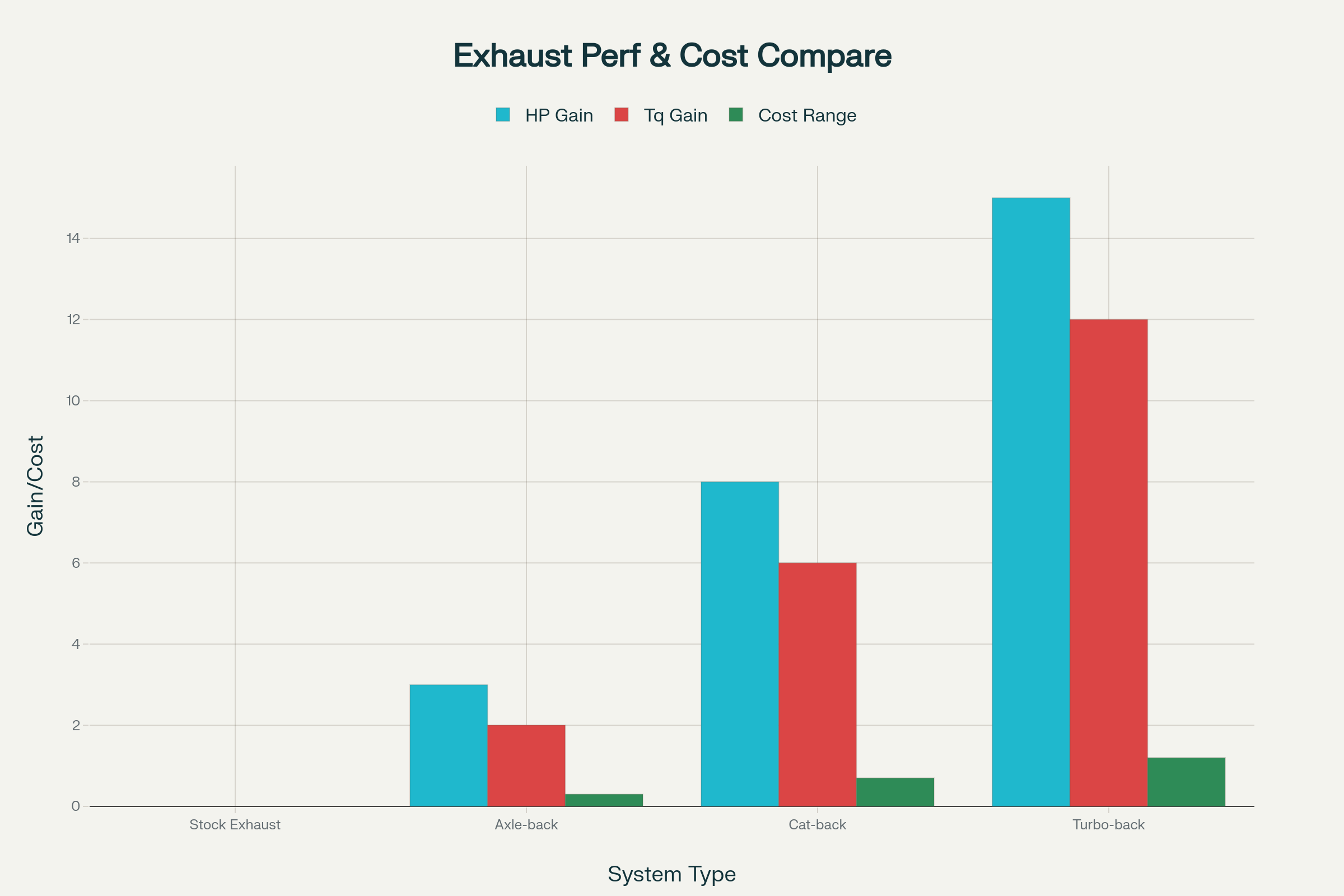

Las ganancias típicas de caballos de fuerza de los sistemas de escape catback oscilan entre 5 y 15 caballos de fuerza en las ruedas, dependiendo de las restricciones del escape de fábrica del vehículo y las características del motor. Los motores atmosféricos a menudo ven mejoras más dramáticas porque dependen completamente de la presión atmosférica para el flujo de aire de admisión, haciendo que la eficiencia del escape sea más crítica. Los motores turboalimentados pueden ver ganancias más pequeñas solo con sistemas catback, pero pueden beneficiarse significativamente cuando se combinan con otras modificaciones.

Las mejoras en el par motor a menudo son más notorias que las ganancias brutas de caballos de fuerza, particularmente en el rango medio de RPM donde ocurre la mayor parte de la conducción diaria. El flujo de escape mejorado aumenta la eficiencia de respiración del motor, permitiendo un mejor llenado de los cilindros y una combustión más completa. Esto se traduce en una mejor respuesta del acelerador y más potencia de tracción para situaciones de conducción del mundo real.

La forma de la curva de rendimiento puede cambiar significativamente con un sistema catback de calidad. Si bien los números de caballos de fuerza pico son importantes, las mejoras más amplias en la curva de par a menudo proporcionan beneficios de rendimiento más significativos para la conducción en carretera. Muchos usuarios informan que sus vehículos se sienten más receptivos y ansiosos en todo el rango de RPM, no solo en los niveles de salida máxima.

Flujo de Escape Mejorado y Contrapresión Reducida

Comprender la reducción de la contrapresión es crucial para apreciar cómo los sistemas de escape catback mejoran el rendimiento. La contrapresión representa la resistencia que encuentran los gases de escape a medida que viajan a través del sistema de escape. Una alta contrapresión obliga al motor a trabajar más para expulsar los gases de escape, reduciendo la potencia de salida y la eficiencia.

Los sistemas de escape de fábrica a menudo incorporan una contrapresión significativa debido a pequeños diámetros de tubería, silenciadores restrictivos y tuberías dobladas por compresión. Estas restricciones pueden ayudar a reducir el ruido y los costos de fabricación, pero limitan el potencial de rendimiento del motor. Los sistemas catback abordan estas restricciones mediante tuberías de mayor diámetro, silenciadores orientados al rendimiento y construcción doblada por mandril.

Las mejoras en la eficiencia del flujo de los sistemas catback benefician la operación del motor de múltiples maneras. Una mejor evacuación del escape permite un flujo de aire de admisión mejorado, creando un ciclo de combustión más eficiente. Esta mejor respiración puede mejorar la atomización del combustible y la eficiencia de la combustión, contribuyendo tanto a mejoras de rendimiento como de economía de combustible.

La velocidad de los gases de escape debe equilibrarse cuidadosamente en el diseño del sistema catback. Si bien las tuberías más grandes reducen la restricción, las tuberías que son demasiado grandes pueden reducir la velocidad de los gases de escape hasta el punto de que disminuyen los efectos de barrido. Los fabricantes profesionales de sistemas catback utilizan pruebas extensas para optimizar el diámetro de la tubería para cada aplicación específica, asegurando los máximos beneficios de rendimiento.

Consideraciones de Economía de Combustible

Muchos propietarios de sistemas de escape catback informan una economía de combustible mejorada, particularmente durante la conducción en carretera. Estas mejoras resultan de que el motor opera de manera más eficiente cuando se reduce la contrapresión del escape. Sin embargo, los cambios en la economía de combustible dependen en gran medida de los hábitos de conducción y la aplicación específica del vehículo.

Comúnmente se informan mejoras en la economía de combustible en carretera de 1 a 3 MPG con sistemas catback de calidad. Las mejoras son más notorias durante el crucero en estado estable donde el motor se beneficia de la reducción de las pérdidas por bombeo. La conducción en ciudad puede mostrar mejoras menos dramáticas porque los patrones frecuentes de aceleración y desaceleración no permiten que las ganancias de eficiencia se manifiesten completamente.

La reducción de la carga del motor contribuye a las mejoras en la economía de combustible cuando los sistemas catback están correctamente diseñados. La contrapresión del escape reducida significa que el motor no trabaja tan duro para expulsar los gases de escape, permitiendo que más energía se transmita a las ruedas en lugar de ser consumida por la resistencia del sistema de escape. Esto es particularmente beneficioso para vehículos que operan frecuentemente bajo carga, como los utilizados para remolcar.

Es importante señalar que un comportamiento de conducción agresivo puede contrarrestar los beneficios de economía de combustible de los sistemas catback. El sonido mejorado y la respuesta del acelerador pueden fomentar una conducción más enérgica, lo que puede aumentar el consumo de combustible a pesar de las mejoras de eficiencia del sistema. El impacto real en la economía de combustible depende en gran medida de los hábitos de conducción individuales y la moderación.

Mejora de la Calidad del Sonido

La mejora del sonido es a menudo el beneficio más inmediatamente notable de instalar un sistema de escape catback. Los sistemas de calidad transforman el sonido a menudo apagado y restrictivo de los escapes de fábrica en notas más envolventes y agresivas que mejoran la experiencia de conducción. Sin embargo, lograr el equilibrio adecuado entre el sonido de rendimiento y la manejabilidad diaria requiere una selección cuidadosa del sistema.

Las notas de escape agresivas de los sistemas catback son el resultado tanto del aumento del flujo como de una ingeniería acústica sofisticada. A diferencia de simplemente quitar los silenciadores, los sistemas catback de calidad utilizan componentes especialmente diseñados para realzar las frecuencias deseables mientras controlan el ruido no deseado. Esta mejora selectiva del sonido produce sonidos de rendimiento satisfactorios sin un volumen excesivo o un zumbido molesto.

Las opciones de personalización del sonido varían significativamente entre los diferentes diseños de sistemas catback y fabricantes. Los diseños de silenciadores con cámara producen los clásicos sonidos de muscle car americano, mientras que los diseños de flujo recto crean notas de estilo europeo más refinadas. Algunos sistemas ofrecen válvulas ajustables que permiten a los conductores modificar la salida de sonido para diferentes situaciones de conducción.

La eliminación del zumbido representa una consideración crucial para los vehículos de uso diario. Los sistemas de escape mal diseñados pueden producir frecuencias de resonancia molestas que hacen que la conducción en autopista sea incómoda. Los sistemas catback premium incorporan resonadores y tecnologías de silenciador cuidadosamente ajustadas para eliminar el zumbido mientras preservan un sonido agresivo en los momentos apropiados.

Proceso de Instalación y Requisitos

Herramientas y Equipo Necesarios

La selección adecuada de herramientas es esencial para una instalación exitosa de un escape catback. Tener el equipo correcto no solo garantiza una instalación adecuada, sino que también previene daños tanto al nuevo sistema como a los componentes existentes del vehículo. La mayoría de las instalaciones de catback requieren tanto herramientas automotrices comunes como algún equipo especializado para obtener los mejores resultados.

Las herramientas manuales esenciales para la instalación de catback incluyen un juego completo de llaves de vaso con tamaños estándar y métricos, que suelen oscilar entre 10 mm y 17 mm. Una llave de torsión es crucial para apretar correctamente las abrazaderas y colgadores del escape según las especificaciones del fabricante. Las llaves combinadas, particularmente los tamaños de 14 mm y 15 mm, son frecuentemente necesarias para la remoción e instalación de los pernos del escape.

El equipo de elevación del vehículo representa la consideración de seguridad más crítica para la instalación de catback. Las instalaciones profesionales suelen utilizar elevadores hidráulicos, pero las instalaciones DIY requieren soportes de gato de calidad y un gato hidráulico de suelo. Nunca intentes trabajar en el escape con solo un gato de coche como soporte: el equipo de seguridad adecuado es esencial para trabajar debajo de un vehículo.

Las herramientas especializadas pueden facilitar significativamente los desafíos de instalación. Las herramientas de remoción de colgadores de escape ayudan a desconectar los colgadores de goma sin daños. Una sierra de vaivén o un cortatubos pueden ser necesarios para quitar los componentes del escape de fábrica obstinados, particularmente en vehículos más antiguos donde la corrosión ha dificultado la remoción. Se debe aplicar WD-40 o un aceite penetrante similar a todos los pernos antes de intentar su remoción.

Guía de Instalación Paso a Paso

La preparación previa a la instalación establece la base para una instalación exitosa del sistema catback. Comienza permitiendo que el vehículo se enfríe por completo si se ha conducido recientemente; los componentes del escape pueden permanecer peligrosamente calientes durante períodos prolongados. Coloca el vehículo en terreno nivelado y activa el freno de mano antes de levantarlo.

La remoción del sistema comienza desde la parte trasera del vehículo y avanza hacia adelante. Comienza desconectando los colgadores del escape, empezando por los colgadores más traseros cerca del silenciador. Sostén el sistema de escape mientras trabajas para evitar que los componentes se caigan. Retira los pernos que conectan el sistema viejo al convertidor catalítico, teniendo cuidado de preservar la junta si está en buen estado.

La instalación del nuevo sistema sigue el proceso inverso, pero requiere una atención cuidadosa a la alineación y al hardware adecuado. Comienza conectando todos los componentes de manera suelta antes de apretar completamente cualquier perno. Esto permite ajustes para garantizar una alineación adecuada y un espacio libre de los componentes de la carrocería del vehículo y las partes de la suspensión. Utiliza las juntas y el hardware nuevos proporcionados con el kit catback para obtener los mejores resultados.

Los ajustes finales y las pruebas completan el proceso de instalación. Aprieta todas las conexiones a las especificaciones del fabricante utilizando una llave de torsión. Arranca el motor y verifica si hay fugas en todos los puntos de conexión. Realiza una prueba de conducción con el vehículo para garantizar un funcionamiento adecuado y escucha cualquier ruido o vibración inusual que pueda indicar problemas de instalación.

Instalación Profesional vs. DIY

La instalación DIY puede ser gratificante y rentable para personas con conocimientos mecánicos. La mayoría de los sistemas catback están diseñados para instalación atornillada utilizando los puntos de montaje de fábrica, lo que los hace accesibles para mecánicos caseros de nivel intermedio. El proceso típicamente requiere de 3 a 6 horas para instaladores primerizos, dependiendo del vehículo específico y la complejidad del sistema.

La instalación profesional ofrece varias ventajas, particularmente para sistemas complejos o mecánicos inexpertos. Los instaladores profesionales tienen equipo especializado, experiencia con varios sistemas y pueden identificar y resolver rápidamente los desafíos de instalación. La mayoría de las instalaciones profesionales toman de 1 a 2 horas y a menudo incluyen garantías en el trabajo de instalación.

Las consideraciones de costo influyen significativamente en la decisión de instalación. La instalación DIY elimina los costos de mano de obra, que típicamente oscilan entre $150 y $400 dependiendo de la ubicación y la complejidad. Sin embargo, comprar las herramientas necesarias para una sola instalación puede compensar estos ahorros. La instalación profesional proporciona tranquilidad y a menudo incluye soporte y ajustes posteriores a la instalación.

Las consideraciones de seguridad nunca deben comprometerse, independientemente de la elección de instalación. El equipo adecuado de elevación y soporte del vehículo es esencial para trabajar de manera segura en el escape. Si no tienes el equipo de seguridad apropiado o experiencia trabajando debajo de vehículos, se recomienda encarecidamente la instalación profesional.

Desafíos Comunes de Instalación

El hardware corroído representa el desafío de instalación más frecuente, particularmente en vehículos más antiguos. Los pernos y colgadores del escape de fábrica pueden corroerse severamente, dificultando o imposibilitando su remoción sin herramientas especializadas. El aceite penetrante aplicado 24-48 horas antes de la instalación puede ayudar, pero los componentes severamente corroídos pueden requerir corte o taladrado para su remoción.

Los problemas de alineación pueden ocurrir incluso con sistemas catback de calidad si no se abordan adecuadamente durante la instalación. Una alineación incorrecta puede hacer que los componentes del escape entren en contacto con la carrocería del vehículo, los componentes de la suspensión o los protectores térmicos, resultando en traqueteos o daños. Tomarse el tiempo para alinear correctamente todos los componentes antes del apriete final previene estos problemas.

Los problemas de espacio libre pueden surgir con vehículos bajados o componentes de suspensión aftermarket. Los sistemas catback estándar están diseñados para la altura de rodadura y la geometría de suspensión de fábrica. Los vehículos modificados pueden requerir un espacio libre adicional o modificaciones del sistema para evitar el contacto con obstáculos en la carretera o componentes del vehículo.

Las fallas de juntas y sellos pueden causar fugas de escape si no se abordan adecuadamente durante la instalación. Siempre utiliza juntas nuevas proporcionadas con los kits catback, y asegúrate de que las superficies de contacto estén limpias antes del ensamblaje. El sellador para escape puede ayudar a garantizar conexiones sin fugas, pero no debe confiarse en él para compensar componentes mal ajustados.

Marcas Populares y Análisis de Costos

Comparación de Fabricantes Líderes

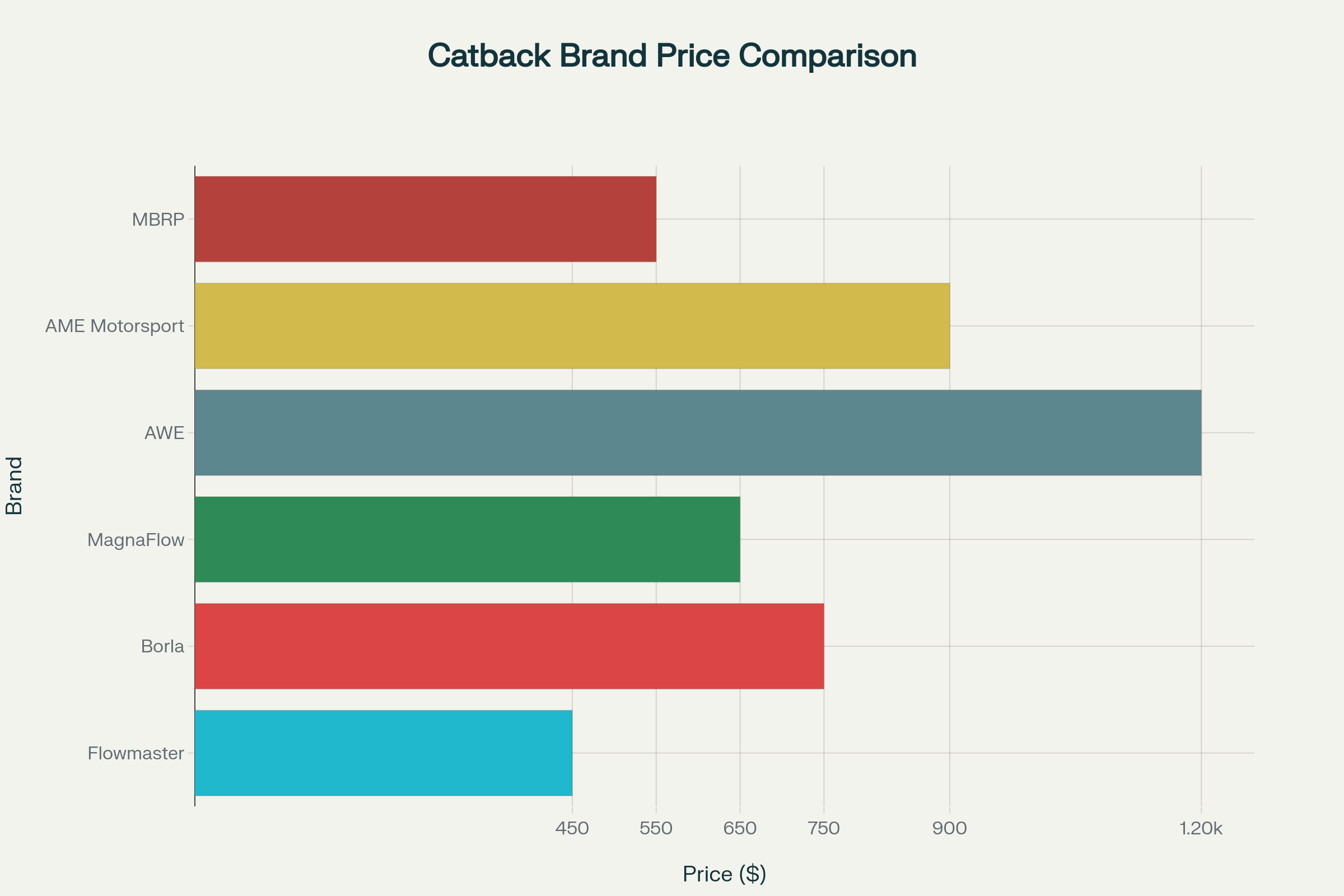

Borla se destaca como la opción premium en sistemas de escape catback, conocidos por su construcción en acero inoxidable T-304 de grado aeroespacial y su tecnología patentada Polyphonic Harmonizer. Sus sistemas suelen oscilar entre $800 y $1500 y vienen con garantías de un millón de millas, lo que refleja confianza en la durabilidad a largo plazo. El diseño de flujo directo de Borla maximiza el flujo mientras que su ingeniería de sonido avanzada elimina los problemas de zumbido.

Flowmaster representa el fabricante de escapes estadounidense clásico, famoso por sus diseños de silenciadores con cámaras que producen el distintivo rugido de los muscle cars. Sus sistemas suelen oscilar entre $400 y $900, lo que los hace más accesibles para los entusiastas con presupuesto limitado. Flowmaster ofrece múltiples niveles de sonido, desde su serie suave Touring hasta la agresiva serie Super, permitiendo personalizar según las preferencias.

MagnaFlow se centra en la tecnología de núcleo perforado de flujo directo envuelto en malla de acero inoxidable. Sus sistemas suelen oscilar entre $500 y $1000 y enfatizan el flujo máximo con características de sonido refinadas. Los sistemas MagnaFlow son populares entre los tuners de importación y propietarios de vehículos europeos que prefieren notas de escape más sofisticadas que los sonidos agresivos de los muscle cars estadounidenses.

AWE Tuning se especializa en aplicaciones específicas para vehículos con una extensa investigación y desarrollo para cada plataforma. Sus sistemas comandan precios premium, típicamente entre $1000 y $2000, pero ofrecen un ajuste, acabado y ganancias de rendimiento excepcionales. Las tecnologías patentadas de cancelación de zumbido de AWE y sus sistemas de válvulas SwitchPath proporcionan opciones sofisticadas de control de sonido.

Rangos de Precio y Consideraciones de Valor

Las opciones económicas en el rango de $400-700 generalmente ofrecen mejoras significativas de rendimiento y sonido sobre los sistemas de fábrica. Marcas como Flowmaster, MBRP y Dynomax proporcionan un buen valor en este segmento de precio, aunque la calidad de materiales y construcción puede no igualar a las alternativas premium. Estos sistemas a menudo utilizan construcción de acero aluminizado para lograr precios más bajos.

Los sistemas de gama media con precios entre $700-1200 representan el punto óptimo para la mayoría de los entusiastas, ofreciendo un rendimiento, sonido y durabilidad excelentes. Este rango de precio incluye series premium de Flowmaster, sistemas Borla de nivel de entrada y aplicaciones de calidad de MagnaFlow. La mayoría de los sistemas en este rango utilizan construcción de acero inoxidable e incluyen garantías integrales.

Los sistemas premium que superan los $1200 generalmente ofrecen lo máximo en rendimiento, calidad de sonido y construcción. Estos sistemas a menudo incluyen características avanzadas como válvulas ajustables, materiales exóticos o ajustes especializados para aplicaciones específicas. Marcas como AWE, Borla de alta gama y tuners especializados comandan estos precios a través de una ingeniería y materiales superiores.

Las consideraciones de valor se extienden más allá del precio de compra inicial para incluir costos de instalación, cobertura de garantía y durabilidad a largo plazo. Un sistema menos costoso que requiera reemplazo en 5 años puede costar finalmente más que un sistema premium que dure 15+ años. Tome en cuenta las tarifas laborales locales para la instalación al comparar costos del sistema, ya que algunos sistemas complejos requieren más tiempo de instalación.

Opciones de Garantía y Soporte

Las garantías del fabricante varían significativamente entre marcas y reflejan la confianza en la calidad del producto. Borla lidera la industria con garantías de un millón de millas en sus sistemas de acero inoxidable, mientras que la mayoría de los otros fabricantes ofrecen cobertura de 2 a 5 años. Flowmaster proporciona garantías limitadas de 3 años o de por vida dependiendo del sistema específico y los materiales.

La cobertura de garantía típicamente incluye defectos en materiales y mano de obra pero puede excluir daños por instalación incorrecta o abuso. Algunos fabricantes requieren instalación profesional para mantener la cobertura de garantía. Los cambios de sonido con el tiempo generalmente no están cubiertos por la garantía, ya que esto se considera operación normal.

La calidad del soporte técnico varía significativamente entre fabricantes. Marcas establecidas como Borla, Flowmaster y MagnaFlow típicamente proporcionan un excelente servicio al cliente y asistencia técnica. Los fabricantes más pequeños o marcas económicas pueden ofrecer recursos de soporte limitados.

La disponibilidad de piezas representa una consideración importante a largo plazo que a menudo se pasa por alto durante la selección inicial del sistema. Los principales fabricantes mantienen inventario de piezas de repuesto para sistemas discontinuados, mientras que las empresas más pequeñas pueden no dar soporte a productos antiguos. Esto puede ser importante para reparaciones o modificaciones años después de la compra original.

Consideraciones Legales y Cumplimiento

Estándares y Regulaciones de Emisiones

La retención del convertidor catalítico es el factor clave que hace que los sistemas de escape catback sean legales en la mayoría de las jurisdicciones. Dado que estos sistemas comienzan después del convertidor catalítico, no interfieren con el equipo de control de emisiones. Este diseño permite que los sistemas catback mantengan el cumplimiento con los estándares de emisiones federales y estatales mientras proporcionan beneficios de rendimiento.

Las regulaciones de la EPA requieren que el equipo de control de emisiones permanezca funcional y sin modificaciones en vehículos conducidos en la calle. Los sistemas de escape catback cumplen con estos requisitos al dejar el convertidor catalítico y los sensores asociados sin alterar. Sin embargo, algunos sistemas catback extremos podrían activar luces de verificación del motor si cambian drásticamente las características de flujo de escape detectadas por los sensores de oxígeno.

Las regulaciones específicas por estado pueden variar significativamente, con California manteniendo los requisitos más estrictos a través de la certificación CARB. Algunos sistemas catback llevan números de aprobación CARB específicos, asegurando el cumplimiento en los 50 estados. Otros estados pueden tener requisitos menos estrictos pero aún prohíben modificaciones que aumenten las emisiones o eliminen el equipo requerido.

Los requisitos de inspección en algunos estados incluyen pruebas de emisiones que podrían verse afectadas por la instalación del sistema catback. Si bien la mayoría de los sistemas catback de calidad no impactan el cumplimiento de emisiones, los sistemas extremadamente ruidosos o modificados podrían atraer atención no deseada durante las inspecciones. Mantener documentación de las especificaciones del sistema puede ayudar durante los procesos de inspección.

Restricciones de Nivel de Ruido

Los límites de decibelios representan la principal restricción legal para los sistemas de escape catback en la mayoría de las áreas. Estos límites típicamente oscilan entre 80-95 decibelios dependiendo del tipo de vehículo y las regulaciones locales. Los vehículos de pasajeros generalmente deben mantenerse por debajo de 90-95 dB, mientras que las motocicletas pueden tener límites diferentes.

Los procedimientos de prueba para el cumplimiento de ruido típicamente involucran mediciones a distancias específicas y niveles de RPM. La aplicación policial generalmente se basa en evaluaciones subjetivas en lugar de mediciones precisas, pero algunas jurisdicciones usan medidores de sonido calibrados. Mantener los niveles de sonido dentro de límites razonables ayuda a evitar atención no deseada de las fuerzas del orden.

Las ordenanzas locales pueden imponer restricciones de ruido más estrictas que los requisitos estatales o federales. Las áreas urbanas y comunidades residenciales a menudo tienen restricciones de ruido que afectan a los vehículos modificados. Algunas áreas prohíben las modificaciones de escape por completo, mientras que otras las permiten solo durante ciertas horas.

Las variaciones en la aplicación significan que el cumplimiento legal puede no prevenir multas en algunas situaciones. Incluso los sistemas de escape legales pueden resultar en multas si los oficiales creen que son excesivamente ruidosos. Mantener documentación que pruebe el cumplimiento del sistema puede ayudar a impugnar multas injustificadas.

Requisitos Específicos por Estado

Los requisitos de California suelen ser los más restrictivos de Estados Unidos, ya que exigen la aprobación de la CARB para muchas modificaciones. Algunos sistemas catback enumeran específicamente el cumplimiento de California, mientras que otros pueden no ser legales para la venta o el uso en el estado. California también aplica multas inmediatas por modificaciones de escape no conformes sin opciones de "ticket de reparación".

Las regulaciones de Nueva York se han vuelto cada vez más estrictas, con límites específicos de decibelios y una mayor aplicación. Los cambios recientes en la ley permiten multas por escapes de posventa que superen los niveles de ruido de fábrica. Esto crea desafíos para determinar el cumplimiento, ya que los niveles de ruido de fábrica no suelen ser especificaciones publicadas.

Texas y Florida mantienen límites de ruido específicos, pero generalmente permiten modificaciones catback que se mantengan dentro de los límites legales. Florida requiere sistemas de escape que funcionen correctamente para evitar ruidos excesivos, mientras que Texas establece límites específicos de decibelios según la velocidad del vehículo.

La jurisdicción federal vs. estatal crea un panorama legal complejo para las modificaciones del escape. Si bien las regulaciones federales de la EPA se centran en el cumplimiento de emisiones, las regulaciones de ruido suelen ser asuntos estatales o locales. Esto significa que un sistema podría ser conforme a nivel federal pero aún violar las ordenanzas locales de ruido.

Desventajas y Problemas Potenciales

Preocupaciones por el Ruido en la Conducción Diaria

El volumen excesivo representa la principal queja sobre los sistemas de escape catback entre los conductores diarios. Lo que suena emocionante durante los paseos de fin de semana puede volverse agotador durante los desplazamientos diarios, particularmente en viajes largos por autopista. El sonido agresivo que atrae a los entusiastas también puede atraer la atención no deseada de las autoridades o los vecinos.

Los problemas de zumbido pueden hacer que la conducción en autopista sea incómoda en sistemas catback mal diseñados. El zumbido ocurre cuando las frecuencias de resonancia del escape coinciden con las frecuencias resonantes del vehículo, creando vibraciones molestas que se sienten en toda la cabina. Los sistemas de calidad incorporan tecnologías de cancelación de zumbido, pero las alternativas económicas pueden no abordar este problema crítico.

Los cambios en el nivel de sonido pueden ocurrir con el tiempo a medida que los componentes del escape envejecen y se acumulan depósitos de carbono. Los sistemas nuevos a menudo suenan diferente a como lo harán después de varios miles de kilómetros de uso. Algunos propietarios encuentran que su nota de escape inicialmente atractiva se vuelve demasiado agresiva o cambia de carácter de maneras que no aprecian.

Las relaciones con los vecinos pueden sufrir cuando se utilizan sistemas de escape agresivos en áreas residenciales, particularmente durante las primeras horas de la mañana o tarde en la noche. Los arranques en frío tienden a ser más ruidosos que la operación normal, lo que potencialmente crea conflictos con los vecinos. Algunas áreas tienen ordenanzas de ruido específicas que restringen la operación de vehículos modificados durante ciertas horas.

Compensaciones entre Costo y Rendimiento

Las ganancias de potencia limitadas en algunos vehículos pueden no justificar el costo significativo de los sistemas catback premium. Los vehículos con escapes de fábrica ya eficientes o motores de pequeña cilindrada pueden ver mejoras de rendimiento mínimas. La relación costo por caballo de fuerza de los sistemas catback puede ser menos favorable que otras modificaciones como las tomas de aire frío o la puesta a punto del motor.

Los rendimientos decrecientes se vuelven evidentes al comparar sistemas catback económicos y premium. Si bien los sistemas premium ofrecen materiales y construcción superiores, las diferencias de rendimiento reales pueden ser mínimas en comparación con alternativas económicas bien diseñadas. La ley de los rendimientos decrecientes se aplica fuertemente a las actualizaciones del sistema de escape.

Los costos de instalación pueden aumentar significativamente la inversión total, particularmente para sistemas complejos o cuando se requiere instalación profesional. Los costos de mano de obra que oscilan entre $150 y $400 pueden representar una parte sustancial del costo total del sistema. La instalación DIY elimina estos costos pero requiere inversión en herramientas y habilidad mecánica.

El impacto en el valor de reventa varía significativamente según el tipo de vehículo y el mercado objetivo. Si bien algunos compradores orientados al rendimiento aprecian las actualizaciones de escape de calidad, otros prefieren configuraciones de stock. Los vehículos modificados pueden tener mercados de reventa más pequeños y podrían ser más difíciles de vender.

Mantenimiento y Longevidad

El desgaste de los componentes afecta a los sistemas catback de manera diferente a los escapes de stock debido a los diferentes materiales y métodos de construcción. Si bien los sistemas de acero inoxidable generalmente duran más que las alternativas de fábrica, aún requieren inspección y mantenimiento periódicos. Los colgantes del escape, las juntas y el hardware de montaje pueden necesitar reemplazo con el tiempo.

Los problemas de corrosión aún pueden ocurrir con sistemas de acero inoxidable en entornos severos, particularmente con exposición a sal en las carreteras. Si bien son más resistentes a la corrosión que los sistemas de stock, ningún sistema de escape es completamente inmune al daño ambiental. La limpieza e inspección regulares pueden ayudar a identificar problemas antes de que se conviertan en problemas graves.

La degradación del rendimiento puede ocurrir a medida que los sistemas acumulan depósitos de carbono y escamas internas. Esto es particularmente cierto para sistemas con estructuras internas complejas o elementos restrictivos de control de sonido. Algunos sistemas pueden requerir limpieza periódica o reemplazo de componentes para mantener un rendimiento óptimo.

Las limitaciones de la garantía pueden no cubrir artículos de desgaste normal o daños por factores ambientales. La mayoría de las garantías se centran en defectos de fabricación en lugar de problemas de vida útil normal del servicio. Comprender las limitaciones de la garantía ayuda a establecer expectativas apropiadas para la longevidad del sistema y los costos de mantenimiento.

Conclusión

Los sistemas de escape catback representan una de las modificaciones más efectivas y accesibles para mejorar el rendimiento del vehículo, el sonido y la experiencia general de conducción. A lo largo de esta guía integral, hemos explorado los aspectos técnicos, beneficios, requisitos de instalación y consideraciones que hacen que los sistemas catback sean actualizaciones tan populares entre los entusiastas del automóvil.

Las ventajas clave de los sistemas de escape catback – incluyendo la mejora de la potencia y el par motor, el flujo de escape mejorado, el potencial de mejor economía de combustible y la calidad de sonido superior – los hacen modificaciones atractivas para una amplia gama de vehículos y estilos de conducción. La retención de los convertidores catalíticos garantiza el cumplimiento legal en la mayoría de las jurisdicciones mientras aún ofrece beneficios de rendimiento significativos.

Al seleccionar un sistema catback, considere sus prioridades específicas: restricciones presupuestarias, características de sonido deseadas, objetivos de rendimiento y regulaciones locales. Los sistemas de calidad de fabricantes establecidos como Borla, Flowmaster, MagnaFlow, AWE y AME Motorsport ofrecen rendimiento y fiabilidad probados, aunque a diferentes puntos de precio para adaptarse a diferentes presupuestos.

El proceso de instalación, aunque manejable para mecánicos DIY experimentados, requiere herramientas adecuadas, equipo de seguridad y atención al detalle. La instalación profesional puede valer la pena para sistemas complejos o cuando la cobertura de garantía es importante. Independientemente de la elección de instalación, la preparación adecuada y los componentes de calidad son esenciales para obtener resultados óptimos.

Comprender el panorama legal que rodea las modificaciones del escape ayuda a evitar problemas de cumplimiento y posibles multas. La mayoría de los sistemas catback cumplen con los requisitos de emisiones, pero las regulaciones de ruido varían significativamente según la ubicación y requieren una consideración cuidadosa durante la selección del sistema.

Si bien los sistemas de escape catback ofrecen numerosos beneficios, las posibles desventajas como los niveles de ruido aumentados, los costos de instalación y los requisitos de mantenimiento deben sopesarse frente a las ventajas. Para la mayoría de los entusiastas, las ganancias de rendimiento, el sonido mejorado y la experiencia de conducción mejorada justifican estas consideraciones.

En última instancia, un sistema de escape catback bien elegido puede transformar el rendimiento y el carácter de su vehículo mientras mantiene la legalidad en la calle y la capacidad de conducción diaria. Ya sea que busque mejoras modestas en el sonido y la eficiencia o ganancias de rendimiento máximas, es probable que haya un sistema catback que coincida con sus necesidades y presupuesto.

La inversión en un sistema de escape catback de calidad generalmente proporciona años de disfrute de conducción mejorado y puede representar un excelente valor cuando se ve como una actualización a largo plazo. Con la selección, instalación y mantenimiento adecuados, estos sistemas ofrecen una de las mejoras más satisfactorias y notables que puede hacer a su vehículo.