When upgrading your vehicle's exhaust system, choosing between an axle back and cat back configuration represents one of the most important decisions you'll make. Both systems offer distinct advantages in terms of performance, sound enhancement, and cost-effectiveness, but understanding their fundamental differences will help you select the perfect modification for your specific needs and budget.

What Is an Axle Back Exhaust System?

An axle back exhaust system represents the most straightforward approach to exhaust modification, replacing only the components located behind your vehicle's rear axle. This targeted upgrade typically includes the muffler, tailpipe, and exhaust tips, making it an excellent entry point for enthusiasts seeking improved sound and aesthetics without extensive modification.

The beauty of axle back systems lies in their simplicity and cost-effectiveness. Since these systems only replace the rear-most components of your exhaust, they require minimal fabrication and can often be installed as direct bolt-on replacements. This approach makes them particularly appealing to newcomers to automotive modification who want to experience the benefits of an upgraded exhaust without the complexity of more comprehensive systems.

Key Components of Axle Back Systems

The primary components of an axle back system work together to create a more aggressive sound while maintaining the factory exhaust flow characteristics up to the rear axle. The muffler represents the heart of the system, designed to provide improved sound quality while managing noise levels. Unlike restrictive factory mufflers that prioritize silence above all else, performance-oriented axle back mufflers balance sound enhancement with reasonable noise control.

Modern axle back systems often feature high-quality exhaust tips that significantly enhance the vehicle's rear aesthetic. These tips come in various sizes, shapes, and finishes, allowing owners to customize their vehicle's appearance while complementing the improved sound characteristics. The tailpipe section connects these components and ensures proper fit with the existing exhaust system forward of the rear axle.

Understanding Cat Back Exhaust Systems

A cat back exhaust system takes a more comprehensive approach to exhaust modification, replacing everything from the catalytic converter outlet to the rear exhaust tips. This extensive modification includes the mid-pipe, resonators (if equipped), mufflers, tailpipes, and exhaust tips, providing a complete overhaul of the exhaust flow path while maintaining emissions compliance.

The term "cat back" specifically refers to the fact that the catalytic converter remains untouched, which has significant legal and practical implications. By maintaining the catalytic converter and other emissions equipment, cat back systems remain street legal in most jurisdictions while providing substantial performance and sound improvements. This approach represents the sweet spot between performance enhancement and regulatory compliance.

Engineering Behind Cat Back Design

Modern cat back systems utilize advanced engineering principles to optimize exhaust gas flow throughout the entire system. The primary focus centers on reducing backpressure through larger diameter piping, typically ranging from 2.5 to 3 inches depending on the vehicle application. However, pipe diameter must be carefully calculated because oversized pipes can actually reduce performance by decreasing exhaust gas velocity.

Professional manufacturers employ mandrel bending techniques to maintain consistent pipe diameter throughout curves and bends. This contrasts with the crush bending commonly used in factory systems, which creates restriction points that impede exhaust flow. The strategic placement of resonators and performance mufflers within cat back systems also optimizes exhaust pulse timing and scavenging effects that can enhance engine performance.

Performance Comparison: Power and Torque Gains

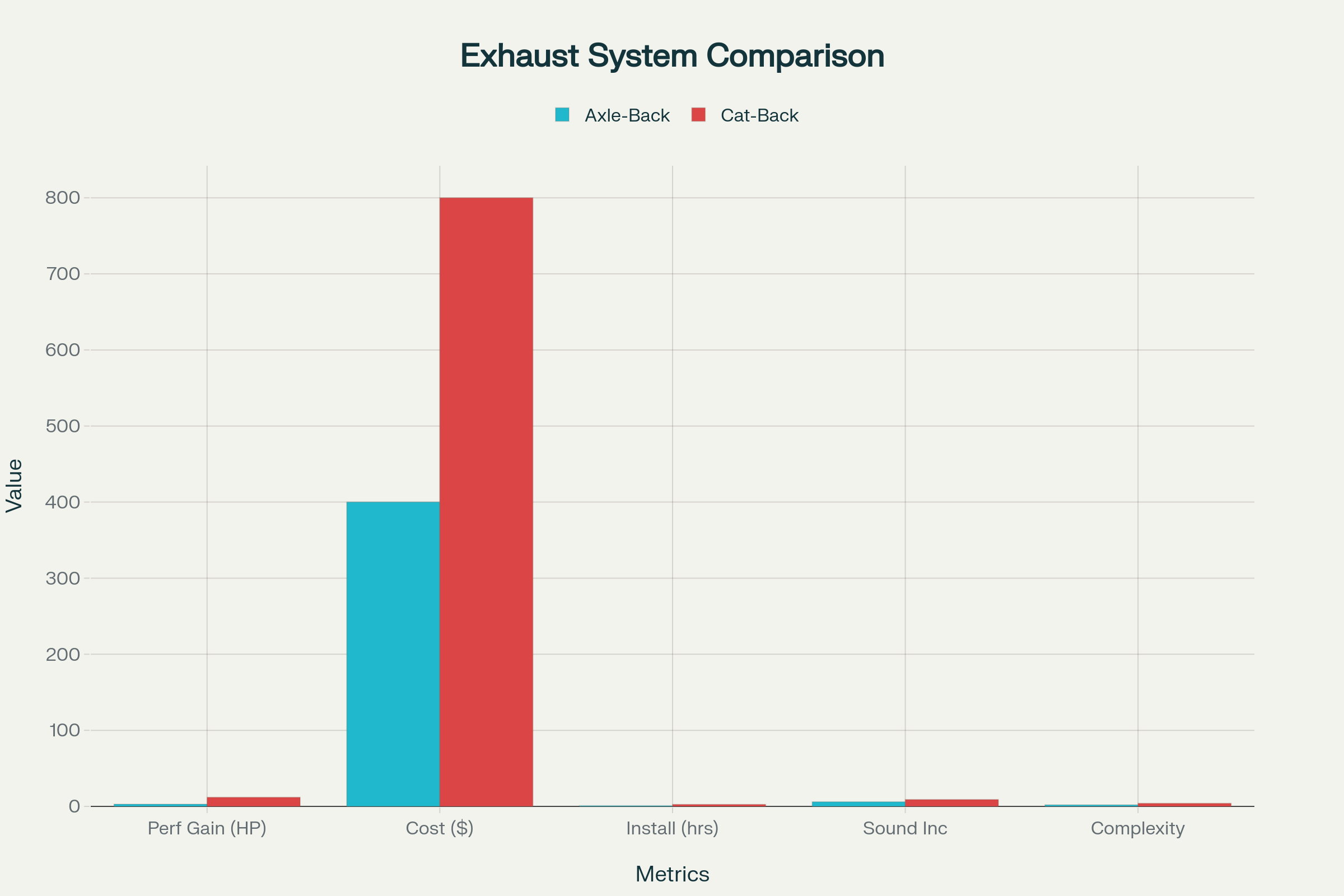

The performance differences between axle back and cat back systems are significant and directly relate to how much of the exhaust system each approach modifies. Understanding these differences helps explain why cat back systems typically command higher prices and installation complexity.

Axle Back Performance Benefits

Axle back systems typically provide modest performance gains, generally ranging from 2 to 5 horsepower at the wheels. These gains result primarily from improved exhaust flow through less restrictive mufflers compared to factory units. While these numbers may seem small, the improvements often translate to noticeable changes in throttle response and exhaust note that enhance the overall driving experience.

The performance limitations of axle back systems stem from the fact that they don't address restrictions in the mid-pipe section or other components forward of the rear axle. Factory mid-pipes often feature smaller diameter tubing and restrictive bends that limit overall system efficiency. However, for vehicles that already have well-flowing exhaust systems from the factory, axle back modifications can provide excellent value for the investment.

Cat Back Performance Advantages

Cat back exhaust systems deliver significantly more substantial performance gains, typically ranging from 5 to 15 horsepower at the wheels depending on the vehicle's factory restrictions and engine characteristics. These improvements result from optimizing the entire exhaust flow path from the catalytic converter back, addressing restrictions throughout the system rather than just the rear section.

The comprehensive nature of cat back systems allows for broader improvements in the engine's power curve. While peak horsepower numbers are important, the enhanced torque delivery throughout the RPM range often provides more meaningful benefits for daily driving. Many users report that their vehicles feel more responsive and eager across the entire power band, not just at peak output levels.

Sound Characteristics and Acoustic Engineering

The sound enhancement capabilities of axle back and cat back systems differ significantly, both in terms of the volume increase and the character of the exhaust note produced. Understanding these differences helps enthusiasts select systems that match their preferences for both performance and auditory experience.

Axle Back Sound Enhancement

Axle back systems focus primarily on modifying sound quality and providing a more aggressive tone compared to stock systems. These systems typically produce a moderate increase in volume while significantly improving the character and depth of the exhaust note. The sound enhancement comes primarily from replacing restrictive factory mufflers with performance-oriented units designed to balance sound quality with reasonable noise levels.

The essence of axle back sound improvement lies in its ability to enhance overall volume while producing a more aggressive sound compared to stock components. This isn't about making excessive noise but rather fine-tuning your vehicle's exhaust voice into something that resonates with power and performance character. The sound characteristics can vary dramatically based on muffler design and internal construction.

Cat Back Acoustic Advantages

Cat back systems typically provide more dramatic sound enhancement due to their comprehensive approach to exhaust modification. By replacing the entire exhaust system from the catalytic converter back, these systems can create more significant changes in both volume and sound character. The larger diameter piping and optimized flow path contribute to a deeper, more resonant exhaust note.

Modern cat back systems often incorporate sophisticated acoustic engineering through strategically placed resonators and performance mufflers. These components work together to produce an aggressive, sporty sound while avoiding harsh drone that can make highway driving uncomfortable. The balance between performance and refinement makes cat back systems particularly appealing to enthusiasts who want improved sound without sacrificing daily drivability.

Installation Process and Complexity

The installation requirements for axle back and cat back systems differ significantly in terms of time, tools, and technical complexity. Understanding these differences helps determine whether DIY installation is feasible or if professional installation is recommended.

Axle Back Installation

Axle back systems are renowned for their installation simplicity, typically requiring only basic hand tools and minimal mechanical experience. Most installations can be completed in 30 minutes to 1.5 hours depending on the specific vehicle and system design. The straightforward nature of axle back installation makes them excellent choices for DIY enthusiasts or those new to automotive modification.

The installation process typically involves removing the factory muffler and tailpipe assembly, then installing the new axle back system using existing mounting points and hangers. Some systems may require minor adjustments to exhaust hangers, but most are designed as direct bolt-on replacements. Professional installation costs typically range from $100 to $300, making the total investment quite reasonable for those who prefer professional installation.

Cat Back Installation Requirements

Cat back systems require more extensive installation procedures, typically taking 1 to 3 hours depending on the complexity of the system and vehicle design. The installation involves removing larger sections of the exhaust system and ensuring proper alignment of multiple components. While still manageable for experienced DIY mechanics, the increased complexity may warrant professional installation for some owners.

Professional installation costs for cat back systems typically range from $200 to $600, reflecting the increased complexity and time requirements. The higher installation costs are often justified by the comprehensive nature of the modification and the precision required to ensure proper fitment and performance. Quality installation is crucial for optimal performance and preventing exhaust leaks or alignment issues.

Cost Analysis and Value Considerations

Understanding the total cost of ownership for axle back versus cat back systems involves considering not just the initial purchase price, but also installation costs, long-term value, and potential resale implications. Both systems offer different value propositions depending on your specific goals and budget constraints.

Axle Back Cost Structure

Axle back systems typically range from $200 to $600 for quality units, making them the more budget-friendly option for exhaust modification. This lower cost reflects the fewer components included and simpler manufacturing requirements. When combined with lower installation costs, axle back systems represent an excellent entry point for enthusiasts working with limited budgets.

The cost-effectiveness of axle back systems becomes even more apparent when considering the sound and aesthetic improvements they provide relative to their investment. While the performance gains may be modest, the dramatic improvement in sound quality and visual appeal often provides excellent satisfaction per dollar spent. This makes axle back systems particularly attractive for owners primarily seeking sound enhancement rather than maximum performance gains.

Cat Back Investment Analysis

Cat back systems typically range from $400 to $1,200 or more for premium units, reflecting their comprehensive nature and more complex manufacturing requirements. While the initial investment is higher, the performance gains per dollar are often superior when considering the substantial improvements in power, torque, and sound quality.

The long-term value proposition of cat back systems often justifies the higher initial cost. These systems typically provide the foundation for additional performance modifications and can complement other upgrades like cold air intakes or engine tuning. The comprehensive nature of cat back systems also means they're less likely to require future upgrades, potentially providing better long-term value.

| Feature | Axle-Back | Cat-Back |

|---|---|---|

| Performance Gains (HP) | 2-5 HP | 5-15 HP |

| Typical Cost Range | $200-600 | $400-1200 |

| Installation Time | 0.5-1.5 hours | 1-3 hours |

| Sound Enhancement | Moderate increase | Significant increase |

| Components Replaced | Muffler, tailpipe, tips | Mid-pipe, muffler, tailpipe, tips |

| Legal Compliance | Generally compliant | Generally compliant |

| Warranty Impact | Minimal impact | Minimal impact |

| Complexity Level | Low | Moderate |

Material Selection and Construction Quality

The materials used in exhaust system construction significantly impact durability, performance, and long-term value. Understanding the differences between material options helps ensure you select a system that meets your performance expectations and environmental conditions.

Common Exhaust Materials

Modern exhaust systems utilize several different materials, each with distinct advantages and limitations. Mild steel represents the most economical option but offers poor corrosion resistance and short lifespan. Aluminized steel provides improved corrosion resistance through a protective coating but still lacks the durability of stainless steel options.

Stainless steel represents the premium choice for exhaust construction, with two primary grades commonly used. 409 stainless steel contains 10.5-11.75% chromium and offers good corrosion resistance at a reasonable price point. 304 stainless steel contains 18-20% chromium and 8-10% nickel, providing superior corrosion resistance and longevity but at higher cost.

Material Performance Characteristics

The choice of materials significantly affects system longevity and performance retention. Stainless steel systems maintain their performance characteristics longer without internal corrosion restricting flow. The exceptional corrosion resistance of stainless steel makes it particularly valuable in harsh environments with road salt, coastal conditions, or extreme weather.

Quality manufacturers often use 304 stainless steel for visible components like tips and resonators, while using 409 stainless steel for hidden sections to balance performance and cost. This approach provides excellent durability where it's most needed while maintaining reasonable pricing for the complete system.

| Material | Corrosion Resistance | Estimated Lifespan | Relative Cost | Magnetic |

|---|---|---|---|---|

| Mild Steel | Poor | 2-3 years | $ | Yes |

| Aluminized Steel | Good | 4-6 years | $$ | Yes |

| 409 Stainless Steel | Better | 8-12 years | $$$ | Yes |

| 304 Stainless Steel | Best | 10-15+ years | $$$$ | No |

Legal Considerations and Compliance

Understanding the legal landscape surrounding exhaust modifications is crucial for avoiding fines, failed inspections, and potential legal complications. Both axle back and cat back systems typically maintain legal compliance, but specific regulations vary by location and application.

Emissions Compliance

Both axle back and cat back systems maintain emissions compliance by preserving the catalytic converter and other emissions control equipment. This design approach ensures that harmful emissions are processed before reaching the modified exhaust components, allowing for performance and sound improvements without compromising environmental responsibilities.

The retention of emissions equipment makes both system types street legal in most jurisdictions, though local regulations may vary. It's essential to verify local laws before installation, as some areas may have specific noise restrictions or modification limitations that could affect system selection.

Noise Regulations

Noise regulations represent the primary legal concern for exhaust modifications, with limits varying significantly by state and municipality. Many jurisdictions enforce decibel limits ranging from 95-104 dB depending on the specific location and vehicle type. Some states require proof that exhaust systems exceed legal limits before issuing citations, while others allow officer discretion.

Modern exhaust systems from reputable manufacturers are typically designed to comply with common noise regulations while still providing enhanced sound quality. However, aggressive systems or those combined with other modifications may exceed legal limits in some areas. It's crucial to research local regulations and select systems designed for legal compliance in your area.

Maintenance Requirements and Longevity

The long-term maintenance requirements and expected lifespan of exhaust systems significantly impact their total cost of ownership and owner satisfaction. Understanding these factors helps make informed decisions about system selection and care.

Routine Maintenance Needs

Both axle back and cat back systems require minimal routine maintenance when constructed from quality materials. Regular visual inspections should check for rust, corrosion, damage, or loose components. These inspections are particularly important for vehicles operated in harsh conditions with road salt, extreme temperatures, or coastal environments.

Cleaning represents the primary maintenance requirement for most exhaust systems. Regular washing removes road salt, dirt, and debris that can accelerate corrosion. Stainless steel systems benefit from periodic cleaning with appropriate metal polish to maintain appearance and remove any surface oxidation that may occur.

Long-term Durability Expectations

Quality stainless steel exhaust systems typically last 10-15 years or more with proper care, often outlasting the vehicles they're installed on. The comprehensive nature of cat back systems may provide better long-term value since they replace more components that would otherwise require future attention.

Professional installation and quality materials significantly impact system longevity. Properly installed systems with quality mounting hardware and gaskets experience fewer failures and maintain performance characteristics longer. The initial investment in professional installation often pays dividends through reduced maintenance requirements and extended system life.

Making the Right Choice: Decision Factors

Selecting between axle back and cat back systems requires careful consideration of your specific priorities, budget constraints, and performance goals. Several key factors should guide this decision to ensure optimal satisfaction with your exhaust upgrade.

Performance Priorities

If maximum performance gains are your primary objective, cat back systems clearly provide superior results through their comprehensive approach to exhaust optimization. The significant horsepower and torque improvements make cat back systems ideal for enthusiasts building high-performance vehicles or those seeking maximum return on investment in terms of measurable performance.

However, if sound enhancement and aesthetic improvement are your main goals, axle back systems often provide excellent value. The dramatic sound improvement and visual enhancement can transform your vehicle's character at a fraction of the cost of comprehensive systems. This makes axle back systems particularly attractive for daily drivers where extreme performance isn't the primary concern.

Budget Considerations

Budget constraints often play a significant role in exhaust system selection, and both options provide value at different price points. Axle back systems excel in providing immediate gratification and noticeable improvements for modest investments. The lower initial cost and installation requirements make them accessible to a broader range of enthusiasts.

Cat back systems require higher initial investment but often provide better long-term value through comprehensive improvements and reduced likelihood of future upgrades. If budget allows, cat back systems typically provide better performance per dollar when considering the substantial improvements across multiple areas.

Future Modification Plans

Consider your long-term modification plans when selecting exhaust systems. If you plan additional performance modifications like cold air intakes, headers, or engine tuning, cat back systems provide better foundation for comprehensive performance builds. The improved flow characteristics complement other modifications more effectively than axle back systems.

Alternatively, axle back systems provide flexibility for future mid-pipe upgrades, essentially allowing you to build a custom cat back system over time. This approach can spread costs across multiple upgrade cycles while providing the flexibility to select specific components that match your evolving preferences.

Installation Best Practices and Professional Tips

Proper installation techniques significantly impact the performance, longevity, and satisfaction with exhaust system upgrades. Following professional best practices ensures optimal results regardless of whether you choose DIY or professional installation.

Preparation and Tool Requirements

Successful exhaust installation begins with proper preparation and tool selection. Essential tools include quality jack stands, socket sets (typically 10mm, 12mm, and 14mm), penetrating oil for rusted hardware, and proper safety equipment. Never attempt exhaust work without proper vehicle support, as the weight of exhaust components can be substantial.

Pre-installation preparation should include applying penetrating oil to exhaust hardware several hours before beginning work. This simple step can prevent broken bolts and significantly reduce installation time. Having replacement gaskets and hardware available prevents delays if original components are damaged during removal.

Professional Installation Techniques

Professional installers emphasize the importance of proper alignment and support during installation. Exhaust systems must be properly aligned to prevent stress on mounting points and ensure optimal performance. Poor alignment can lead to premature failure, exhaust leaks, and performance degradation.

Quality installation includes checking all connections for proper sealing and ensuring adequate clearance from vehicle components, heat shields, and body panels. Professional installers also verify that exhaust hangers properly support the system weight without creating stress points that could lead to future failures.

Common Mistakes and How to Avoid Them

Understanding common mistakes in exhaust system selection and installation helps avoid costly errors and ensures optimal results from your investment. These mistakes can significantly impact performance, legality, and long-term satisfaction.

Selection Mistakes

One of the most common mistakes involves selecting systems based solely on price without considering material quality, fitment, or manufacturer reputation. Cheap exhaust systems often use inferior materials that fail prematurely and may not provide proper fitment. Investing in quality systems from established manufacturers typically provides better long-term value and satisfaction.

Another frequent error involves ignoring local noise regulations when selecting aggressive exhaust systems. While loud exhausts may sound appealing, citations and legal issues can quickly offset any enjoyment gained. Research local laws and select systems designed for compliance in your area.

Installation Errors

Improper installation techniques can negate the benefits of quality exhaust systems and create expensive problems. Common errors include inadequate support during installation, failure to properly align components, and reusing damaged gaskets or hardware. These mistakes can lead to exhaust leaks, premature failure, and poor performance.

Rushing installation often leads to mistakes that could be easily avoided with proper preparation and patience. Take time to properly support components, apply thread locker to hardware, and verify proper alignment before final tightening. Quality installation practices ensure optimal performance and longevity from your exhaust investment.

Conclusion: Making the Best Choice for Your Vehicle

The decision between axle back and cat back exhaust systems ultimately depends on your specific priorities, budget, and performance goals. Both options provide meaningful improvements over factory systems, but they serve different purposes and provide distinct value propositions.

Axle back systems excel for enthusiasts primarily seeking sound enhancement and aesthetic improvement at reasonable cost. Their simple installation, lower price point, and dramatic sound improvement make them excellent choices for daily drivers and budget-conscious enthusiasts. The modest performance gains, while not dramatic, often provide noticeable improvements in throttle response and driving satisfaction.

Cat back systems shine when maximum performance improvement is the primary objective. Their comprehensive approach to exhaust optimization delivers substantially greater power and torque gains while providing superior sound enhancement. The higher initial investment often proves worthwhile for serious performance enthusiasts and those building comprehensive performance packages.

Both system types maintain legal compliance through preservation of emissions equipment, making them suitable for street-driven vehicles in most jurisdictions. Material selection significantly impacts longevity and performance retention, with stainless steel construction providing optimal durability and long-term value.

Consider your specific needs, budget constraints, and long-term modification plans when making this decision. Whether you choose the cost-effective sound enhancement of an axle back system or the comprehensive performance improvement of a cat back system, selecting quality components from reputable manufacturers and ensuring proper installation will provide years of enhanced driving enjoyment.

The exhaust system upgrade represents one of the most satisfying modifications you can make to your vehicle, providing immediate improvements in sound, performance, and driving experience. By understanding the differences between axle back and cat back systems and selecting the option that best matches your priorities, you'll enjoy the benefits of this essential modification for years to come.