Straight Pipe vs Catback Exhaust: The Ultimate Performance Comparison Guide

When it comes to enhancing your vehicle's performance and sound, choosing between a straight pipe and catback exhaust system represents one of the most significant decisions you'll make as an automotive enthusiast. Both modifications promise improved performance, enhanced sound, and a more engaging driving experience, but they differ dramatically in their approach, legality, and overall impact on your vehicle. This comprehensive guide will break down everything you need to know about these two popular exhaust modifications, helping you make an informed decision that aligns with your performance goals, budget, and legal requirements.

Understanding Exhaust System Fundamentals

Before diving into the specific differences between straight pipe and catback systems, it's essential to understand how your vehicle's exhaust system functions and why modifications can dramatically impact performance. Your car's exhaust system serves multiple critical functions beyond simply expelling burnt gases from the engine.

The primary purpose of any exhaust system is to create an efficient path for exhaust gases to exit the engine, reducing backpressure and allowing the engine to breathe more effectively. When an engine can expel exhaust gases more efficiently, it creates space for a cleaner, fuller intake charge on the next combustion cycle, ultimately leading to improved performance. Additionally, the exhaust system plays a crucial role in emissions control through components like catalytic converters, which convert harmful pollutants into less dangerous substances.

Modern factory exhaust systems represent a careful balance between performance, cost, emissions compliance, and noise regulations. Manufacturers must design systems that meet stringent environmental standards while keeping production costs manageable and noise levels within acceptable limits for daily driving. This balancing act often results in compromises that leave significant performance potential on the table, which is where aftermarket modifications come into play.

The science behind exhaust modifications centers on fluid dynamics and the principle of reducing backpressure. Backpressure represents the resistance that exhaust gases encounter as they travel through the system. High backpressure forces the engine to work harder to expel gases, reducing power output and efficiency. By optimizing exhaust flow through larger diameter pipes, smoother bends, and less restrictive components, both straight pipe and catback systems aim to improve this fundamental aspect of engine operation.

What is a Straight Pipe Exhaust System?

A straight pipe exhaust system represents the most aggressive approach to exhaust modification, eliminating virtually all restrictive components between the engine and the atmosphere. In its purest form, a straight pipe system removes the mufflers, resonators, and catalytic converters, replacing them with a single, uninterrupted pipe that runs from the exhaust manifold directly to the tailpipe.

The concept behind straight piping is elegantly simple: create the most direct, unrestricted path possible for exhaust gases to exit the engine. By removing all components that could impede exhaust flow, straight pipe systems theoretically provide maximum performance gains and the most aggressive exhaust note possible. This approach is particularly popular in racing applications where emissions regulations don't apply and maximum performance takes precedence over all other considerations.

However, the term "straight pipe" has evolved beyond its literal definition in automotive culture. Many enthusiasts use the term to describe any exhaust modification that significantly reduces restrictions, even if some components remain. This broader interpretation can include systems that remove only the muffler and resonator while retaining the catalytic converter, though these would more accurately be called "catless" systems rather than true straight pipes.

The construction of a straight pipe system typically involves custom fabrication work, as most vehicles don't have bolt-on straight pipe options available. This custom approach allows for optimization of pipe diameter and routing for specific applications, but it also increases complexity and cost compared to pre-manufactured systems. Professional fabrication ensures proper fitment and optimal performance, though some enthusiasts attempt DIY installations with varying degrees of success.

Straight Pipe Performance Benefits and Characteristics

The performance benefits of straight pipe exhaust systems can be substantial, particularly on high-performance engines that produce significant exhaust flow. By eliminating all restrictions in the exhaust path, straight pipes allow engines to expel gases with minimal resistance, potentially unlocking significant horsepower and torque gains.

On naturally aspirated engines, straight pipe systems can provide noticeable improvements in horsepower and torque across the entire RPM range. The research indicates that high-performance naturally aspirated engines can see gains of 50 or more horsepower with a properly designed straight pipe system. These gains are particularly pronounced at higher RPMs where exhaust flow becomes most critical to engine performance.

For turbocharged engines, straight pipe systems can provide even more dramatic benefits by reducing backpressure on the turbocharger. Lower backpressure allows the turbo to spool more quickly and operate more efficiently, resulting in improved throttle response and power delivery. However, the removal of catalytic converters can disrupt the careful tuning balance that manufacturers establish, potentially requiring ECU modifications to maintain optimal performance.

The weight reduction benefits of straight pipe systems shouldn't be overlooked. Removing heavy components like catalytic converters, mufflers, and resonators can save 20-40 pounds or more depending on the vehicle. This weight reduction improves the vehicle's power-to-weight ratio and can positively impact acceleration, braking, and handling characteristics.

The sound characteristics of straight pipe systems are unmistakable and often the primary motivation for the modification. Without any sound dampening components, straight pipes produce an extremely loud, raw exhaust note that varies dramatically based on engine configuration. V8 engines with straight pipes produce a distinctive rumble and crackle that many enthusiasts find irresistible, though the volume levels often exceed acceptable limits for daily driving and legal requirements.

What is a Catback Exhaust System?

A catback exhaust system takes a more measured approach to performance enhancement, replacing only the components located "back" from the catalytic converter to the rear of the vehicle. This strategic approach maintains the catalytic converter and other emissions equipment while optimizing the sections of the exhaust system that have the most significant impact on sound and moderate performance improvements.

The typical catback system includes the mid-pipe that connects to the catalytic converter outlet, performance-oriented mufflers, resonators (if equipped), tailpipes, and exhaust tips. By maintaining the catalytic converter in the system, catback modifications remain street legal in most jurisdictions while still providing meaningful performance and sound improvements.

The engineering behind catback systems focuses on optimizing exhaust flow through larger diameter pipes, mandrel bending techniques, and performance-oriented muffler designs. Unlike the crush-bent pipes often used in factory systems, quality catback systems utilize mandrel bending to maintain consistent pipe diameter throughout turns and curves. This consistency ensures smooth exhaust flow without restriction points that can create turbulence and reduce performance.

Modern catback systems often incorporate sophisticated acoustic engineering through strategically placed resonators and performance mufflers. These components work together to produce an aggressive, sporty sound while avoiding the harsh drone that can make highway driving uncomfortable. The balance between performance and refinement makes catback systems particularly appealing to enthusiasts who want improved performance without sacrificing daily drivability.

Catback Performance Benefits and Real-World Impact

Catback exhaust systems provide meaningful performance improvements while maintaining the refinement and legal compliance necessary for daily driving. Research indicates that properly designed catback systems typically provide horsepower gains ranging from 5 to 15 horsepower at the wheels, depending on the vehicle's factory exhaust restrictions and engine characteristics.

The performance improvements from catback systems result from reducing exhaust backpressure through larger diameter pipes and less restrictive mufflers. While the gains may seem modest compared to straight pipe systems, they represent significant improvements for street-driven vehicles where broad powerband improvements matter more than peak numbers. Many users report that their vehicles feel more responsive and eager throughout the entire RPM range, not just at peak output levels.

Fuel economy improvements are commonly reported with quality catback systems, particularly during highway driving. Highway fuel economy improvements of 1-3 MPG are typical as the engine operates more efficiently when exhaust backpressure is reduced. The engine doesn't work as hard to expel exhaust gases, allowing more energy to be transmitted to the wheels rather than being consumed by exhaust system resistance.

Weight reduction benefits, while less dramatic than straight pipe systems, still contribute to improved performance. Quality catback systems often weigh less than factory systems due to optimized designs and premium materials like stainless steel. The weight savings, combined with performance improvements, create a noticeable improvement in vehicle dynamics.

The sound characteristics of catback systems strike a balance between aggressive performance tone and daily drivability. Unlike straight pipes, catback systems produce a deeper, more refined exhaust note that enhances the driving experience without becoming overwhelming. The strategic use of resonators and performance mufflers allows manufacturers to tune the sound signature for specific vehicle applications.

Legal Considerations and Regulatory Compliance

The legal landscape surrounding exhaust modifications varies dramatically between straight pipe and catback systems, with implications that extend far beyond simple performance considerations. Understanding these legal differences is crucial for making an informed decision about exhaust modifications.

Straight pipe exhaust systems face significant legal challenges across the United States. According to current federal regulations, straight pipe systems are illegal for street use in all 50 states because they bypass or remove federally mandated emissions control equipment. The Environmental Protection Agency (EPA) strictly prohibits the removal of catalytic converters on street-driven vehicles, making true straight pipe systems exclusively legal for off-road or track use only.

The consequences of running an illegal straight pipe system can be severe and expensive. Penalties can range from fines of $100-$500 per violation to more serious consequences including failed emissions testing, insurance complications, and potential vehicle impoundment in extreme cases. States like California enforce particularly strict penalties, with some violations carrying fines of thousands of dollars.

Catback exhaust systems generally maintain street legality because they preserve the catalytic converter and other federally mandated emissions equipment. However, legality isn't automatic – catback systems must still comply with local noise ordinances and state-specific regulations. Some jurisdictions have strict decibel limits that aggressive catback systems might exceed, potentially leading to citations for excessive noise.

The regulatory landscape continues to evolve, with many states implementing stricter enforcement and higher penalties for non-compliant exhaust modifications. Even in states with historically lenient enforcement, federal oversight and environmental concerns are driving increased scrutiny of exhaust modifications. This trend makes the legal compliance of catback systems increasingly valuable for enthusiasts who want performance improvements without legal risks.

Sound Characteristics and Acoustic Engineering

The sound characteristics of straight pipe and catback exhaust systems represent perhaps the most immediately noticeable difference between these two approaches to exhaust modification. Understanding how each system produces its distinctive sound signature helps enthusiasts make informed decisions based on their acoustic preferences and practical requirements.

Straight pipe exhaust systems produce the most aggressive and unfiltered engine sound possible. Without any sound dampening components, every aspect of the engine's combustion process becomes audible, creating a raw, powerful sound that varies dramatically based on engine configuration. V8 engines with straight pipes produce a distinctive rumble, crackle, and pop that many enthusiasts find irresistible, while smaller engines may sound harsh or raspy without proper acoustic tuning.

However, the extreme volume levels of straight pipe systems often create practical problems. The sound levels frequently exceed local noise ordinances and can become fatiguing during extended driving. Highway cruising with a straight pipe system can create an uncomfortable drone that interferes with conversation, audio systems, and even the driver's ability to hear important engine sounds that might indicate mechanical issues.

Catback exhaust systems employ sophisticated acoustic engineering to produce an aggressive yet refined sound signature. Performance mufflers and strategically placed resonators work together to enhance desirable sound frequencies while suppressing harsh or droning tones. This selective sound filtering allows catback systems to produce exciting performance sounds without the overwhelming volume of straight pipes.

The acoustic tuning of catback systems often varies by manufacturer and specific application. Some systems prioritize deep, rumbling tones for muscle cars and trucks, while others focus on higher-pitched, more exotic sounds for sports cars. Many modern catback systems incorporate valved designs that allow drivers to adjust sound levels electronically, providing both aggressive performance sound and quiet cruising capability in a single system.

Installation Complexity and Professional Requirements

The installation requirements for straight pipe and catback exhaust systems differ significantly in complexity, time requirements, and skill level needed for successful completion. Understanding these differences helps enthusiasts budget appropriately and determine whether professional installation is necessary.

Straight pipe installation typically requires custom fabrication work rather than simple bolt-on installation. Most vehicles don't have pre-manufactured straight pipe systems available, necessitating custom pipe work, welding, and fitting. This custom approach requires specialized tools, welding equipment, and fabrication skills that exceed the capabilities of most DIY enthusiasts. Professional installation costs for straight pipe systems can range from $300-$800 depending on the complexity of the custom work required.

The fabrication process for straight pipe systems involves removing existing components, measuring and cutting new pipe sections, and welding everything together in a configuration that optimizes flow while fitting properly under the vehicle. Proper installation requires attention to ground clearance, heat shielding, and mounting points to ensure the system doesn't contact the chassis or create safety hazards.

Catback exhaust installation is typically much more straightforward, with most systems designed for bolt-on installation using factory mounting points. Quality catback systems include all necessary hardware, clamps, and detailed instructions for installation. Many enthusiasts with basic mechanical skills and common tools can successfully install catback systems in their own garage.

Professional installation costs for catback systems typically range from $250-$600 depending on the complexity of the system and local labor rates. The installation process usually takes 1-3 hours for experienced technicians, making it a relatively quick and straightforward procedure. Some shops offer installation services at significantly lower rates when the customer provides the parts, making professional installation affordable even for budget-conscious enthusiasts.

Cost Analysis and Long-Term Value Considerations

The financial implications of choosing between straight pipe and catback exhaust systems extend far beyond the initial purchase and installation costs, encompassing potential legal expenses, maintenance requirements, and resale value impacts. A comprehensive cost analysis reveals that the apparent savings of straight pipe systems often disappear when long-term costs are considered.

Initial costs for straight pipe systems appear attractive, with materials costs typically ranging from $200-$500 for basic setups. However, the custom fabrication required for proper installation adds $300-$800 in labor costs, bringing total initial investment to $500-$1,300. The seemingly lower upfront cost becomes misleading when potential legal consequences are factored into the equation.

The hidden costs of straight pipe systems can be substantial and ongoing. Potential fines for illegal exhaust modifications range from $100-$500 per violation, with some states imposing much higher penalties. Failed emissions testing can require expensive remediation work or temporary reinstallation of legal components. Insurance complications may arise if modifications contribute to accidents or violations, potentially affecting coverage or claims.

Catback exhaust systems require higher initial investment, with quality systems ranging from $600-$2,500 depending on materials, brand, and complexity. Installation costs add another $250-$600, bringing total initial investment to $850-$3,100. However, these systems provide long-term value through legal compliance, warranty coverage, and positive impact on resale value.

The long-term cost comparison strongly favors catback systems when all factors are considered.

Over a five-year ownership period, a straight pipe system with conservative estimates of legal complications could cost $5,500 or more, while even premium catback systems rarely exceed $3,000 total cost. This analysis doesn't include potential costs from insurance issues, remediation requirements, or negative impact on resale value.

Environmental Impact and Emissions Considerations

The environmental implications of exhaust modifications have become increasingly important as emissions regulations tighten and environmental awareness grows. The differences between straight pipe and catback systems in terms of environmental impact are dramatic and have far-reaching consequences beyond individual vehicle performance.

Straight pipe exhaust systems create significant environmental concerns by removing or bypassing catalytic converters, which are designed to reduce harmful emissions by up to 90% or more. Without these critical components, vehicles emit substantially higher levels of carbon monoxide, nitrogen oxides, and unburned hydrocarbons. These pollutants contribute directly to air quality problems, smog formation, and health issues in urban areas.

The emissions impact of straight pipe systems varies by engine type and operating conditions, but the increases are always substantial. Even well-tuned engines without catalytic converters produce emissions levels that far exceed federal standards. This environmental impact has prompted increasingly strict enforcement and penalties for non-compliant exhaust modifications.

Catback exhaust systems maintain environmental compliance by preserving catalytic converters and other emissions control equipment. These systems can actually improve emissions characteristics by optimizing exhaust flow and helping engines operate more efficiently. Some catback systems incorporate high-flow catalytic converters that provide better performance while maintaining or even improving emissions control.

The broader environmental impact of exhaust modifications extends beyond individual vehicles to influence regulatory trends and enforcement policies. Areas with significant air quality challenges are implementing stricter enforcement of exhaust modification regulations, with penalties that continue to increase. This trend makes the environmental compliance of catback systems increasingly valuable for long-term viability.

Performance Optimization and Tuning Considerations

Maximizing the performance benefits of either straight pipe or catback exhaust systems often requires complementary modifications and professional tuning to achieve optimal results. Understanding these requirements helps enthusiasts plan comprehensive performance upgrades that work together synergistically.

Straight pipe exhaust systems typically require ECU tuning to achieve optimal performance and prevent potential engine damage. Removing catalytic converters and other components can disrupt the carefully calibrated air-fuel ratios and sensor readings that modern engines rely on. Without proper tuning, straight pipe systems may cause check engine lights, poor drivability, or even engine damage from incorrect fuel delivery.

The tuning requirements for straight pipe systems can be complex and expensive, often requiring specialized knowledge and equipment. Professional tuning services can cost $500-$1,500 or more depending on the complexity of the modifications and the specific vehicle. Additionally, tuned vehicles may require premium fuel and more frequent maintenance to maintain optimal performance and reliability.

Catback exhaust systems typically don't require ECU modifications for basic installation, making them more user-friendly for enthusiasts who want improved performance without complex tuning requirements. However, complementary modifications like cold air intakes, headers, or ECU tuning can amplify the benefits of catback systems significantly.

The synergistic effects of multiple performance modifications often provide better overall results than any single modification alone. A well-planned combination of intake, exhaust, and tuning modifications can provide performance gains that exceed the sum of individual components. This integrated approach to performance modification often makes catback systems the foundation for broader performance upgrade plans.

Maintenance Requirements and Long-Term Reliability

The maintenance and reliability characteristics of straight pipe and catback exhaust systems vary significantly, with implications for long-term ownership costs and satisfaction. Understanding these differences helps enthusiasts prepare for the ongoing requirements of their chosen exhaust modification.

Straight pipe exhaust systems offer simplicity advantages through their minimalist design. With fewer components to fail or require maintenance, properly constructed straight pipe systems can be very reliable. However, the custom fabrication nature of most installations can create quality variations that affect long-term durability. Poor welding, inadequate materials, or improper mounting can lead to failures that require expensive repairs.

The harsh operating environment of straight pipe systems, without the heat shielding and sound dampening of factory components, can accelerate wear on surrounding vehicle components. Increased heat and vibration may affect nearby components like wiring, hoses, or body panels. Additionally, the lack of oxygen sensors and other monitoring equipment in straight pipe systems can mask developing engine problems that would normally trigger warning systems.

Catback exhaust systems typically incorporate higher quality materials and construction techniques that enhance long-term reliability. Premium stainless steel construction resists corrosion and maintains performance characteristics over many years of service. Quality catback systems often include warranties that provide protection against manufacturing defects and premature failure.

The maintenance requirements for catback systems are generally minimal, typically involving periodic inspection of mounting points and connections. However, the more complex designs of some catback systems, particularly those with valves or electronic components, may require additional maintenance attention. Regular cleaning and inspection help maintain both performance and appearance over the long term.

Choosing the Right System for Your Needs

Selecting between straight pipe and catback exhaust systems requires careful consideration of multiple factors including performance goals, legal requirements, budget constraints, and intended use. The decision should align with your specific priorities and circumstances rather than following generic recommendations.

For track-only or off-road vehicles where legal compliance isn't a concern, straight pipe systems offer maximum performance potential and weight reduction benefits. Race cars, dedicated track vehicles, and off-road builds can take full advantage of straight pipe performance without legal or environmental concerns. The aggressive sound and maximum flow characteristics make straight pipes ideal for competitive applications where every horsepower matters.

Daily drivers and street-legal vehicles benefit most from catback exhaust systems that provide performance improvements while maintaining legal compliance and refinement. The balance of performance, sound, and practicality makes catback systems ideal for enthusiasts who want enhanced driving experiences without compromising daily usability. Catback systems also provide better long-term value through legal compliance and positive resale impact.

Climate and regional considerations play important roles in exhaust system selection. Areas with strict emissions testing, noise ordinances, or aggressive enforcement make catback systems the practical choice. Regions with harsh weather conditions may favor stainless steel catback systems for their corrosion resistance.

Budget considerations should include long-term costs rather than just initial investment. While straight pipe systems appear cheaper initially, the potential for legal complications, insurance issues, and negative resale impact often makes catback systems more economical over time. Quality catback systems provide better value through legal compliance, warranty coverage, and enhanced resale value.

Future Trends and Technology Developments

The exhaust modification industry continues to evolve with new technologies, materials, and regulatory requirements that influence the straight pipe versus catback decision. Understanding these trends helps enthusiasts make informed decisions that remain relevant as the automotive landscape changes.

Advanced materials like titanium and carbon fiber are becoming more accessible in catback exhaust systems, offering unprecedented weight reduction and performance benefits. These premium materials provide strength-to-weight ratios that approach or exceed straight pipe systems while maintaining all the refinement and legal compliance advantages of catback designs. As manufacturing costs decrease, these advanced materials are becoming viable options for more applications.

Electronic valve technology is revolutionizing catback exhaust systems by providing variable sound and performance characteristics. Modern valved exhaust systems can provide quiet operation for daily driving and aggressive performance sound for spirited driving, all controlled electronically. This technology eliminates many of the compromises traditionally associated with catback systems.

Emissions regulations continue to tighten globally, with enforcement becoming more sophisticated and penalties increasing. Advanced monitoring systems and remote sensing technology make it increasingly difficult to operate non-compliant exhaust systems without detection. This regulatory trend strongly favors catback systems that maintain emissions compliance while providing performance benefits.

Hybrid and electric vehicle adoption is changing the automotive landscape, but internal combustion engines will remain relevant for many years. High-performance internal combustion engines are likely to become more sophisticated and efficient, making properly designed catback systems even more valuable for extracting maximum performance while maintaining compliance.

Summary and Recommendations

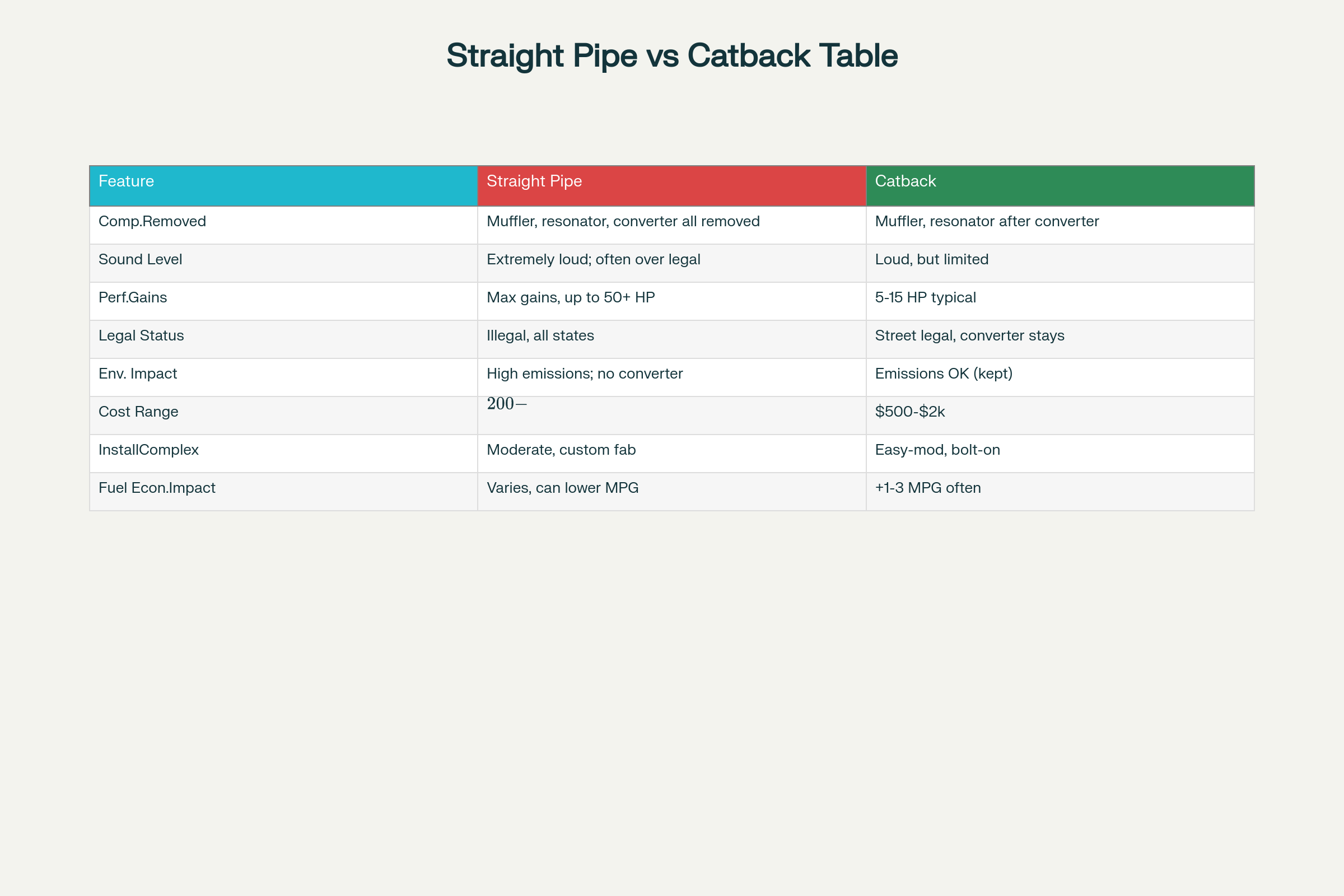

The choice between straight pipe and catback exhaust systems ultimately depends on your specific priorities, intended use, and circumstances. Both approaches offer distinct advantages and drawbacks that make them suitable for different applications and enthusiast needs.

Straight pipe exhaust systems provide maximum performance potential, aggressive sound characteristics, and weight reduction benefits that make them ideal for track-only vehicles and competitive applications. However, their illegal status for street use, environmental impact, and potential for excessive noise make them impractical for daily driven vehicles. The long-term costs associated with legal complications often exceed the initial savings, making straight pipes economically questionable for most enthusiasts.

Catback exhaust systems offer the optimal balance of performance improvement, sound enhancement, and practical usability for street-driven vehicles. Their legal compliance, refinement, and positive impact on resale value make them the clear choice for daily drivers and weekend enthusiasts. While initial costs are higher, the long-term value proposition strongly favors catback systems for most applications.

For enthusiasts building dedicated track cars or off-road vehicles, straight pipe systems can provide maximum performance without legal concerns. However, the vast majority of enthusiasts will find catback systems provide better overall value through their combination of performance, legality, and refinement. The advancing technology in catback systems, including electronic valves and premium materials, continues to close the performance gap while maintaining all the practical advantages.

The decision should be based on honest assessment of your priorities, intended use, and tolerance for legal risk. If maximum performance is the only consideration and legal compliance isn't required, straight pipes may be appropriate. For everyone else, a quality catback exhaust system provides the best combination of performance, sound, legality, and long-term value in the exhaust modification landscape.

The automotive enthusiasm community benefits from informed decision-making that considers all factors rather than focusing solely on peak performance numbers. By understanding the complete picture of straight pipe versus catback exhaust systems, enthusiasts can make choices that enhance their driving experience while maintaining practical usability and legal compliance for years of enjoyment.