Carbon Fiber Wheel Damage: A Comprehensive Guide to Prevention, Identification, and Repair

Carbon fiber wheels represent the pinnacle of automotive and cycling performance technology, offering exceptional strength-to-weight ratios and aerodynamic advantages. However, these high-performance components require specialized knowledge and care to prevent damage and maintain optimal functionality. Understanding the various types of damage that can affect carbon fiber wheels, along with proper prevention and maintenance strategies, is essential for anyone investing in this premium technology.

Understanding Carbon Fiber Wheel Construction

Carbon fiber wheels utilize a composite material structure consisting of carbon fiber layers bound together with epoxy resin. This construction method creates components that are incredibly strong in specific directions while remaining lightweight. The manufacturing process typically involves either pre-preg (pre-impregnated) carbon fiber or vacuum-bagged wet layup techniques, with pre-preg offering superior consistency and strength characteristics.

The unique properties of carbon fiber make these wheels exceptionally rigid and responsive, but also create specific vulnerabilities that differ significantly from traditional aluminum wheels. Unlike metal wheels that typically bend or deform when damaged, carbon fiber wheels are more likely to crack or experience delamination when subjected to excessive stress.

Modern carbon fiber wheels incorporate advanced resin systems and manufacturing techniques designed to improve durability and heat resistance. Quality manufacturers use specialized clear coat finishes that provide UV protection and enhance the material's resistance to environmental degradation.

Primary Types of Carbon Fiber Wheel Damage

Impact Damage: The Most Common Threat

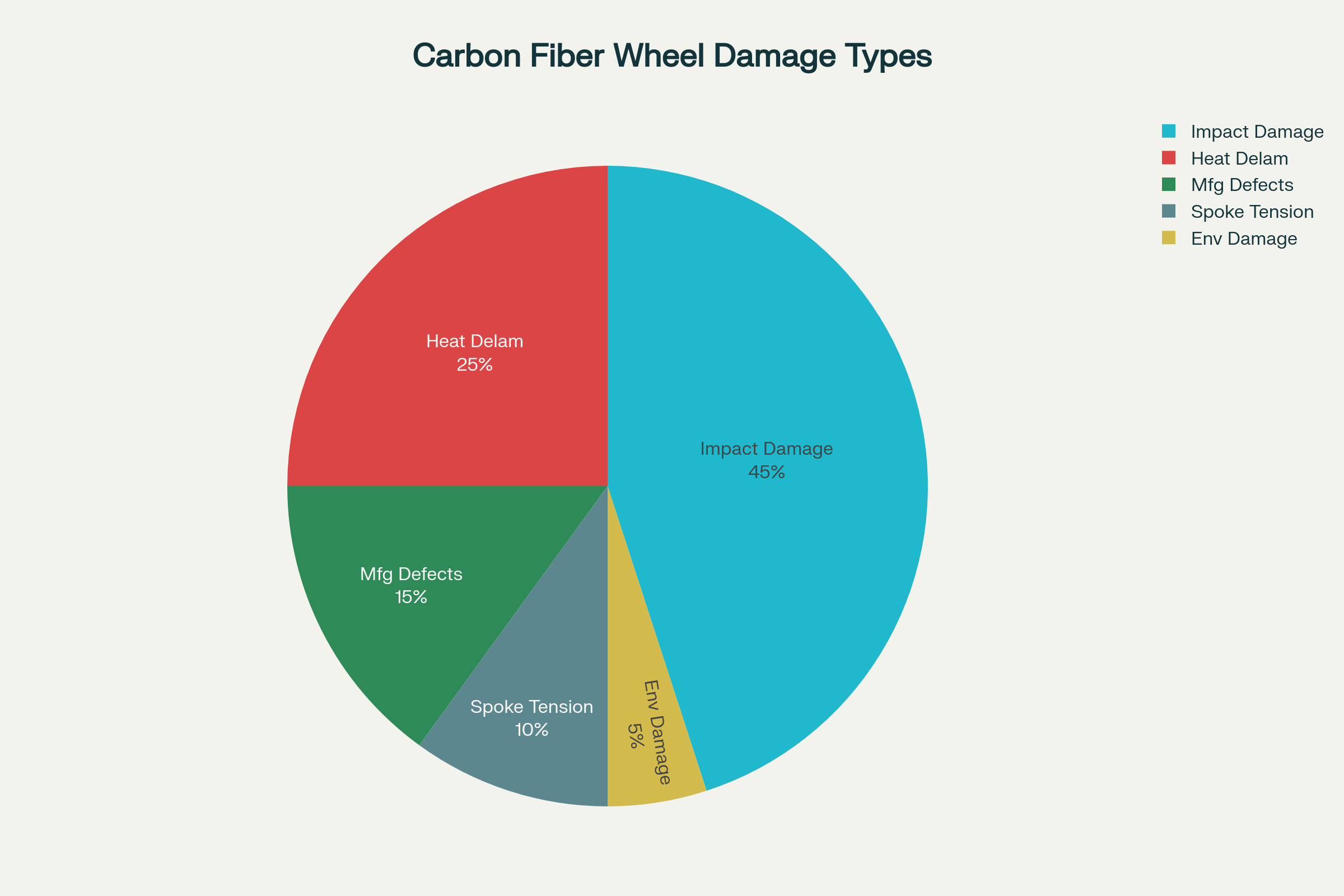

Impact damage represents the most frequent cause of carbon fiber wheel failure, accounting for approximately 45% of all damage cases. This type of damage occurs when wheels strike potholes, curbs, rocks, or other road hazards at speed. Unlike aluminum wheels that might dent or bend, carbon fiber wheels are more likely to crack or suffer catastrophic failure when subjected to sharp impacts.

The vulnerability of carbon fiber to impact damage stems from the material's brittleness compared to metals. While carbon fiber excels at handling distributed loads and gradual stress application, sudden concentrated forces can exceed the material's limits and cause cracking or delamination. Pothole impacts are particularly dangerous because they create concentrated stress points that can initiate crack propagation throughout the wheel structure.

Several factors influence the severity of impact damage, including tire pressure, wheel speed, and the angle of impact. Low tire pressure increases the risk of rim strikes by reducing the protective cushion between the wheel and road surface. High-speed impacts amplify the forces involved, making even relatively minor road imperfections potentially damaging.

Heat-Related Delamination

Heat damage represents the second most common form of carbon fiber wheel failure, particularly affecting wheels equipped with rim brakes. Extended braking on long descents can raise rim temperatures above 150°C (300°F), creating conditions that stress the carbon-resin interface and potentially cause delamination.

The physics behind heat damage involves the conversion of kinetic energy into thermal energy during braking. While aluminum wheels effectively dissipate this heat throughout their structure, carbon fiber's poor thermal conductivity causes heat to concentrate at the brake surface. This concentrated heat can soften or damage the epoxy resin that binds the carbon fibers together, leading to layer separation or delamination.

Heat-related damage often manifests as bubbling, discoloration, or soft spots on the brake surface. In severe cases, the rim structure can deform or completely fail, creating dangerous riding conditions. The risk is particularly high during extended descents where continuous braking generates sustained heat buildup.

Manufacturing Defects and Quality Issues

Manufacturing defects, while less common due to improved quality control processes, can create hidden weaknesses that lead to premature failure. These defects typically occur during the layup, curing, or finishing processes and may not become apparent until the wheel experiences stress during use.

Common manufacturing defects include inadequate resin distribution, contamination between layers, improper curing temperatures or times, and insufficient pressure during the molding process. These issues can create void spaces, weak bonds between layers, or areas of inadequate resin penetration that compromise structural integrity.

Recent recalls, such as the DT Swiss carbon wheel recall involving over 6,000 units, highlight how manufacturing defects can affect even reputable brands. The recalled wheels experienced separation of the outermost carbon layer around the rim flange, demonstrating how subtle manufacturing issues can create significant safety concerns.

Spoke Tension and Structural Issues

Improper spoke tension creates another significant category of carbon fiber wheel damage. Excessive tension can stress spoke holes and cause cracking around these critical areas, while insufficient tension allows wheel flex that can lead to fatigue failure over time.

Carbon fiber wheels require precise spoke tensioning to maintain structural integrity and performance characteristics. Unlike steel wheels that can tolerate some variation in spoke tension, carbon fiber wheels demand more consistent and carefully controlled tension patterns. Uneven tension can create stress concentrations that initiate crack formation and propagation.

The challenge with spoke tension in carbon fiber wheels is that the material provides fewer warning signs before failure compared to metal wheels. While a loose spoke in an aluminum wheel might cause noticeable wobbling or noise, carbon fiber wheels can maintain apparent functionality even with developing structural problems.

Environmental and Chemical Damage Factors

Environmental factors contribute to carbon fiber wheel degradation through various mechanisms. Ultraviolet radiation from sunlight can break down the resin matrix over time, leading to surface degradation and eventual structural weakness. Temperature cycling between hot and cold conditions creates expansion and contraction stresses that can contribute to delamination.

Chemical exposure from road salt, cleaning products, or fuel spills can also damage carbon fiber wheels. Harsh chemicals or inappropriate cleaning agents can attack the resin matrix or clear coat finish, creating pathways for moisture infiltration and accelerated degradation.

Moisture ingress represents a particularly insidious form of environmental damage. Water penetration into the carbon fiber structure can lead to freeze-thaw damage in cold climates and can interfere with the carbon-resin bond integrity. This type of damage often develops gradually and may not become apparent until structural failure occurs.

Early Detection and Inspection Techniques

Regular inspection represents the most effective strategy for identifying carbon fiber wheel damage before it becomes dangerous. Visual inspection should be conducted after every ride, focusing on areas most susceptible to damage such as spoke holes, brake surfaces, and rim edges.

The tap test provides a simple but effective method for identifying internal damage. A healthy wheel produces a consistent, clear ring when tapped gently with a coin or plastic tool. Dull or dead spots in the sound may indicate internal delamination or void formation that compromises structural integrity.

Advanced inspection techniques include using bright lights to examine the wheel structure for hairline cracks or discoloration patterns that might indicate developing problems. Professional inspection services can employ ultrasonic testing or other non-destructive evaluation methods to assess internal structural condition.

Prevention Strategies and Best Practices

Preventing carbon fiber wheel damage requires a comprehensive approach addressing the primary failure mechanisms. Maintaining proper tire pressure represents one of the most effective prevention strategies, as adequate pressure provides cushioning that protects wheels from impact damage.

Selecting appropriate brake pads for carbon fiber wheels is crucial for preventing heat-related damage. Carbon-specific brake pads are formulated to manage heat buildup and provide consistent performance without overheating the rim surface. These pads typically use softer compounds that dissipate heat more effectively than standard pads designed for aluminum wheels.

Proper braking technique becomes critical when using carbon fiber wheels with rim brakes. Feathering the brakes during descents, rather than applying continuous pressure, allows heat dissipation between braking events and prevents dangerous temperature buildup.

Storage and handling practices significantly impact carbon fiber wheel longevity. Wheels should be stored in cool, dry locations away from direct sunlight and potential impact hazards. When transporting wheels, protective bags or cases prevent accidental damage and reduce exposure to harmful environmental factors.

Maintenance Schedules and Procedures

Establishing a regular maintenance routine is essential for carbon fiber wheel longevity and performance. Daily maintenance should include visual inspection for obvious damage and basic cleaning to remove corrosive contaminants such as brake dust and road salt.

Weekly maintenance involves more thorough cleaning with appropriate detergents and inspection of brake surfaces for wear or heat damage. Monthly inspections should include spoke tension assessment and hub bearing condition evaluation.

Professional maintenance services should be scheduled annually or after significant mileage accumulation. These services can identify developing problems that might not be apparent during routine inspections and ensure that all components remain within safe operating parameters.

Seasonal maintenance becomes particularly important for wheels used in harsh environmental conditions. Winter storage preparation should include thorough cleaning, inspection, and application of protective treatments to prevent corrosion and environmental damage during storage periods.

Repair Options and Limitations

Carbon fiber wheel repair capabilities are significantly more limited than those for metal wheels. Minor surface damage such as scratches or small chips in the clear coat may be repairable through professional refinishing services, but structural damage typically requires wheel replacement.

Delamination damage rarely allows for safe repair, as the compromised bond between carbon layers affects the wheel's overall structural integrity. Attempting to repair delaminated areas often results in further damage and creates safety risks that outweigh any potential cost savings.

Professional assessment is crucial when considering repair options. Qualified technicians can evaluate damage extent and determine whether repair is feasible or if replacement is necessary for safe operation. Many manufacturers void warranties if repairs are attempted by unauthorized service providers.

Choosing Quality Products and Manufacturers

Selecting carbon fiber wheels from reputable manufacturers significantly reduces the risk of defects and premature failure. Established manufacturers typically employ rigorous quality control processes and use proven materials and construction techniques that enhance durability and reliability.

Pre-preg carbon fiber construction generally offers superior performance and durability compared to wet layup techniques. Pre-preg materials provide more consistent resin distribution and better control over the curing process, resulting in wheels with more predictable performance characteristics and longer service life.

Warranty coverage and customer support should factor into purchasing decisions. Reputable manufacturers typically offer comprehensive warranties that protect against manufacturing defects and provide clear procedures for addressing problems if they occur.

Economic Considerations and Total Cost of Ownership

The total cost of carbon fiber wheel ownership extends beyond the initial purchase price to include maintenance, potential repairs, and replacement costs. While carbon fiber wheels offer performance advantages, their higher initial cost and limited repairability create different economic considerations compared to traditional wheel materials.

Insurance considerations become important for high-value carbon fiber wheels, as replacement costs can be substantial. Some insurance policies may not provide adequate coverage for aftermarket wheels, making separate coverage or documented valuations important for protecting the investment.

Resale value for carbon fiber wheels depends heavily on condition and maintenance history. Well-maintained wheels from reputable manufacturers typically retain value better than those showing signs of damage or neglect, making proper care an important economic consideration.

Future Developments and Technological Advances

Carbon fiber wheel technology continues evolving with improvements in materials, manufacturing processes, and design optimization. Advanced resin systems offer better heat resistance and durability, while improved manufacturing techniques reduce the risk of defects and enhance consistency.

Hybrid construction methods combining carbon fiber with other materials may offer improved impact resistance while maintaining weight and performance advantages. These approaches could address some current limitations of pure carbon fiber construction.

Monitoring and diagnostic technologies may eventually provide real-time feedback on wheel condition and stress levels. Such systems could warn of developing problems before they become dangerous and optimize maintenance schedules based on actual usage patterns.

Conclusion

Carbon fiber wheel technology offers exceptional performance benefits for automotive and cycling applications, but requires specialized knowledge and care to realize these advantages safely and economically. Understanding the various damage mechanisms, implementing appropriate prevention strategies, and maintaining regular inspection schedules are essential for maximizing the value and safety of these premium components.

The key to successful carbon fiber wheel ownership lies in recognizing that these components behave differently from traditional materials and require adapted maintenance and handling practices. While the initial investment and ongoing care requirements may be higher than conventional wheels, the performance advantages and technological sophistication of carbon fiber wheels continue to make them attractive to serious enthusiasts and professionals.

By following established best practices, choosing quality products from reputable manufacturers, and maintaining vigilant inspection and maintenance routines, carbon fiber wheel owners can enjoy the benefits of this advanced technology while minimizing the risks of damage and premature failure. As technology continues advancing, carbon fiber wheels will likely become even more durable and accessible, but the fundamental principles of proper care and maintenance will remain essential for safe and successful operation.