Installing carbon fiber wheel tubs represents one of the most significant modifications you can make to your racing or performance vehicle. These lightweight, high-strength components not only accommodate larger tires for improved traction but also reduce unsprung weight while maintaining structural integrity under extreme racing conditions. This comprehensive guide breaks down the entire installation process into four manageable steps, ensuring professional results every time.

Carbon fiber wheel tubs have revolutionized automotive performance modifications, offering superior strength-to-weight ratios compared to traditional steel alternatives. Professional race teams and serious enthusiasts choose carbon fiber tubs for their ability to handle massive tire sizes while contributing to overall vehicle weight reduction. The installation process, while technical, can be accomplished with proper planning and attention to detail.

Understanding Carbon Fiber Wheel Tubs

What Are Carbon Fiber Wheel Tubs?

Carbon fiber wheel tubs are precision-engineered replacement wheel wells designed to accommodate significantly larger tires than stock configurations allow. These components are manufactured using advanced composite materials, typically featuring hand-laid carbon cloth with fire-retardant resin, followed by vacuum-bag curing to eliminate air bubbles and ensure optimal strength.

The manufacturing process creates components that are not only incredibly strong but also remarkably lightweight. A properly constructed 47-inch diameter carbon fiber wheel tub weighs approximately one pound, compared to steel equivalents that can weigh ten times as much. This weight reduction occurs in a critical area of the vehicle, as unsprung weight directly affects handling, acceleration, and braking performance.

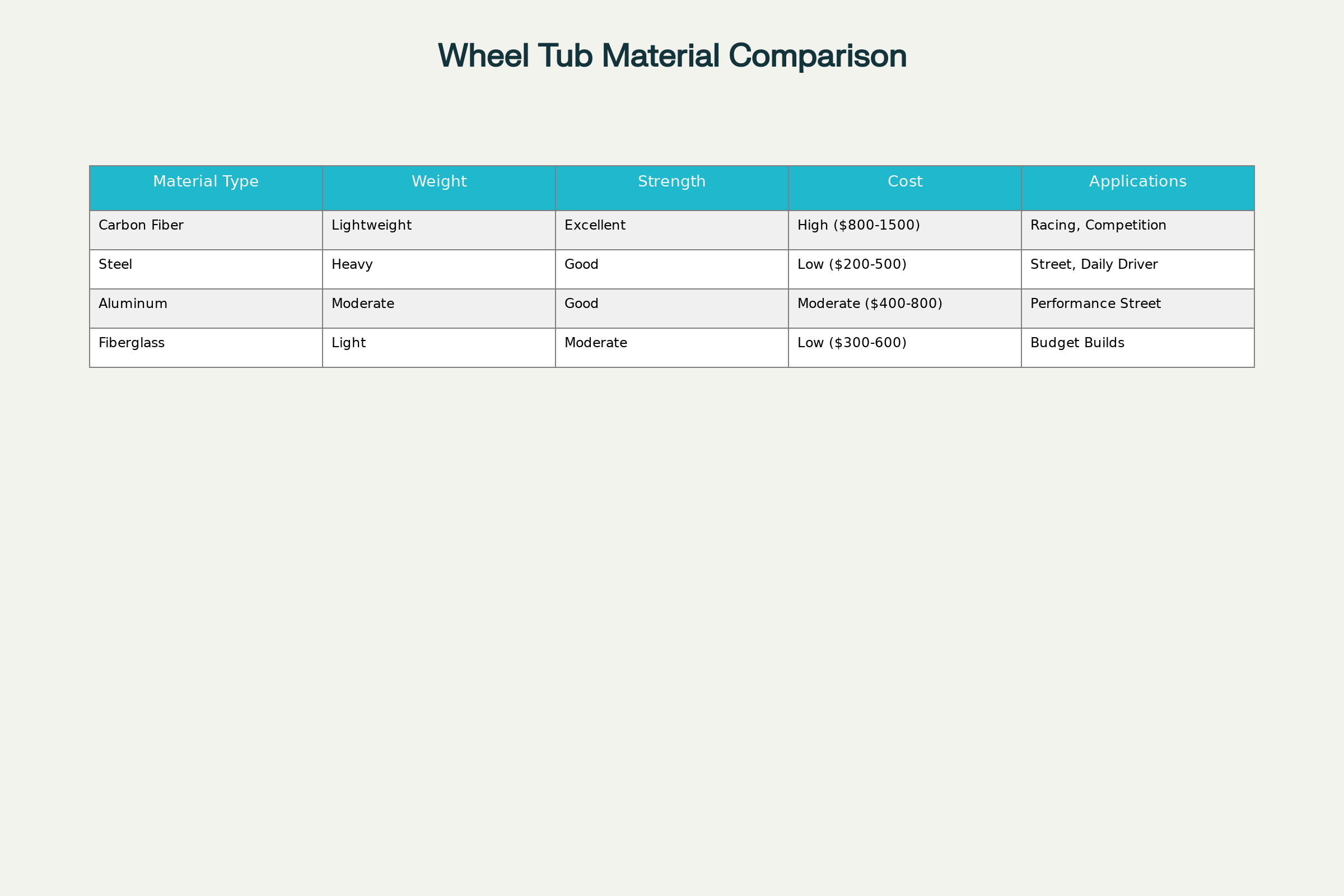

Why Choose Carbon Fiber Over Alternatives?

The material comparison reveals why carbon fiber has become the preferred choice for serious performance applications. Unlike steel tubs that add significant weight and aluminum options that may lack ultimate strength, carbon fiber provides the ideal balance of properties. The material's anisotropic nature allows engineers to orient fibers in specific directions to handle expected loads, creating components that exceed the strength of metal alternatives while weighing a fraction as much.

Professional racing applications have validated carbon fiber's performance credentials. Formula One teams now utilize bio-based carbon fiber composites on technically demanding components like brake duct wheel shields, demonstrating the material's ability to withstand extreme racing conditions. This technology advancement has filtered down to consumer applications, making professional-grade carbon fiber components accessible to serious enthusiasts.

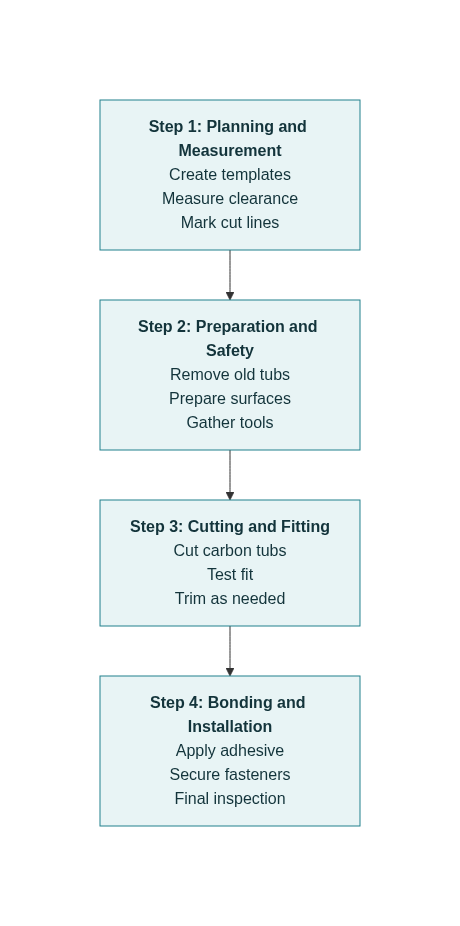

Step 1: Planning and Measurement Phase

Essential Pre-Installation Assessment

The foundation of any successful wheel tub installation begins with comprehensive planning and precise measurements. This phase determines the entire project's success and prevents costly mistakes during fabrication and installation. Professional fabricators emphasize that proper planning can reduce installation time by up to 50% while ensuring optimal fitment.

Begin by evaluating your vehicle's current wheel well configuration and determining the maximum tire size you intend to accommodate. Consider both current requirements and future upgrade possibilities, as modifying wheel tubs after installation becomes significantly more complex and expensive. Document the vehicle's suspension geometry, noting any components that might interfere with enlarged wheel wells.

Creating Accurate Templates

The template creation process requires exceptional precision and patience. Professional installers recommend using heavy corrugated cardboard for initial templates, as this material is easily workable yet sturdy enough for accurate transfer to carbon fiber components. The process involves several critical steps that ensure perfect fitment.

Start by creating a 47-inch diameter circle (or your chosen size) on cardboard using a compass or string method. Cut this template carefully and test-fit it against the intended mounting location. Use a level to ensure the template sits properly aligned with the vehicle's geometry. Mark all interference points, mounting holes, and clearance requirements directly onto the template.

The template must account for the tub's wrap around the quarter panel area. Create secondary templates for these curved sections, using masking tape to bridge gaps and achieve tight conformance to the body contours. This attention to detail during templating prevents fitment issues during final installation.

Measuring Clearance Requirements

Accurate clearance measurements prevent interference with suspension components, brake systems, and body panels. Use proper measuring tools including straightedges, measuring tape, and C-clamps to determine available space. Take measurements at multiple points including horizontal, 45-degree, and 90-degree positions from the hub center.

Critical clearance points include:

-

Suspension component clearance: Measure distances to struts, springs, control arms, and sway bars

-

Brake system clearance: Ensure adequate space for calipers, rotors, and brake lines

-

Body panel clearance: Verify sufficient space to fender lips and quarter panels

-

Tire clearance: Account for tire growth under load and suspension travel

Professional installers recommend maintaining at least 10-15mm clearance from moving components to prevent contact during suspension compression or steering input. Document all measurements carefully, as these will guide both fabrication and final installation procedures.

Step 2: Preparation and Safety Phase

Safety Equipment and Workspace Setup

Carbon fiber work requires specialized safety precautions due to the material's dust generation during cutting and the chemical exposure from adhesives. Proper personal protective equipment (PPE) includes safety glasses, respiratory protection, gloves, and ventilation systems. The workspace should be well-ventilated with dust collection capabilities when possible.

Essential safety equipment includes:

-

Respiratory protection: Use appropriate masks or respirators rated for composite dust

-

Eye protection: Safety glasses or goggles to prevent fiber fragments from entering eyes

-

Skin protection: Long sleeves and gloves to prevent skin irritation from carbon fiber dust

-

Ventilation: Proper airflow to remove airborne particles and chemical vapors

Surface Preparation Techniques

Proper surface preparation ensures optimal adhesion between the carbon fiber tub and the vehicle structure. This process involves cleaning, degreasing, and abrading surfaces to create ideal bonding conditions. Professional-grade surface preparation can increase bond strength by up to 300% compared to inadequately prepared surfaces.

Begin by thoroughly cleaning all mounting surfaces with appropriate solvents such as acetone or isopropyl alcohol. Remove all traces of paint, undercoating, rust, or contamination from areas where the tub will bond to the chassis or body panels. Use 120-grit sandpaper to create surface texture that promotes mechanical adhesion.

Tool and Material Preparation

Organize all necessary tools and materials before beginning the installation process. This preparation prevents delays during critical bonding phases when adhesives have limited working time. Professional installers create detailed checklists to ensure nothing is overlooked during the actual installation.

Required tools include:

-

Cutting equipment: Diamond blades, jigsaws, or specialized composite cutting tools

-

Measuring instruments: Precision measuring tapes, squares, and levels

-

Fastening hardware: Machine screws, rivets, and panel bonding adhesives

-

Surface preparation tools: Sanders, abrasives, and cleaning solvents

Material preparation involves conditioning adhesives to proper temperatures and ensuring all components are clean and ready for installation. Many structural adhesives require specific temperature ranges for optimal curing, making environmental control an important consideration.

Step 3: Cutting and Fitting Phase

Carbon Fiber Cutting Techniques

Cutting carbon fiber requires specialized techniques to prevent delamination, burning, and fraying that can compromise the material's structural integrity. Professional fabricators use specific blade types and cutting speeds to achieve clean, precise cuts while minimizing waste.

The optimal cutting approach depends on the specific carbon fiber construction and thickness. For most wheel tub applications, use fine-toothed diamond blades at moderate speeds with adequate cooling. Wet cutting methods help control dust and prevent overheating that can damage the resin matrix. Always cut slightly oversize to allow for final trimming and fitting adjustments.

Common Cutting Issues and Solutions

Several problems commonly arise during carbon fiber cutting, each requiring specific solutions to maintain component integrity:

Delamination prevention: This occurs when individual layers separate during cutting. Slow cutting speeds and sharp blades minimize this issue. Support both sides of the cut line to prevent material breakaway as the cut progresses.

Overheating control: Excessive heat causes resin flow and material degradation. Use cutting fluids or periodic cooling breaks for thick sections. Monitor blade temperature and replace when cutting performance degrades.

Edge quality management: Frayed edges compromise both appearance and structural performance. Post-cutting sanding with fine-grit abrasives creates smooth, professional edges while removing loose fibers.

Test Fitting Procedures

Proper test fitting prevents major issues during final assembly and ensures optimal component alignment. This process involves multiple fitting cycles with progressive refinement until perfect fitment is achieved. Professional installers never rush this phase, as corrections become increasingly difficult once adhesives are applied.

Begin with rough fitting to verify overall dimensions and clearances. Mark any interference points or areas requiring additional trimming. Use temporary fasteners or clamps to hold the tub in position while checking alignment with suspension components and body panels. Make incremental adjustments rather than large corrections to maintain dimensional accuracy.

Document the final fitting configuration with photographs and measurements. This documentation proves invaluable during reassembly and provides reference points for any future modifications. Pay particular attention to mounting point alignment, as these locations experience the highest structural loads during operation.

Step 4: Bonding and Installation Phase

Adhesive Selection and Application

The final installation phase requires careful selection and application of structural adhesives that will permanently bond the carbon fiber tub to the vehicle structure. Professional-grade panel bonding adhesives provide the necessary strength and durability for racing applications.

Most installations benefit from two-part epoxy adhesives specifically formulated for carbon fiber applications. 3M Scotch-Weld DP-420 NS represents the industry standard, offering excellent bond strength with "no sag" characteristics that prevent adhesive runoff during curing. Consider the adhesive's working time, environmental requirements, and final strength characteristics when making selections.

Proper Bonding Techniques

Successful bonding requires attention to environmental conditions, surface preparation, and application techniques. Optimal bonding occurs at temperatures between 70-80°F with relative humidity below 50%. Clean all bonding surfaces immediately before adhesive application to remove any contamination.

Apply adhesive liberally to both surfaces, ensuring 100% coverage of the bonding area. When joining surfaces, adequate squeeze-out should be visible around the bond line, indicating proper adhesive distribution. Remove excess adhesive immediately while still workable to prevent finishing problems later.

Mechanical Fastening Requirements

While adhesive bonding provides primary structural attachment, mechanical fasteners add redundancy and distribute loads across larger areas. Professional installations combine panel bonding with strategically placed machine screws or rivets for maximum security.

Fastener placement should avoid high-stress areas while providing adequate load distribution. Use corrosion-resistant hardware such as stainless steel or aluminum to prevent galvanic corrosion between dissimilar materials. Apply thread-locking compounds to prevent fastener loosening under vibration.

Curing and Final Inspection

Proper curing ensures the adhesive reaches full strength before the vehicle returns to service. Most structural adhesives require 24-48 hours for complete cure at room temperature, though elevated temperatures can accelerate this process. Maintain proper support and alignment during the entire curing period.

Conduct thorough inspection after curing completion, checking for:

-

Bond line integrity: Verify complete adhesion without voids or gaps

-

Fastener torque: Confirm all mechanical fasteners meet specifications

-

Clearance verification: Re-check all clearances with suspension at various positions

-

Surface finish: Address any cosmetic issues before final assembly

Troubleshooting Common Installation Issues

Fitment Problems

Despite careful templating, fitment issues occasionally arise during installation. Most problems stem from inadequate initial measurements or changes in vehicle configuration since templating. Address fitment problems systematically rather than forcing components into place, as this can create stress concentrations that lead to premature failure.

Common fitment solutions include:

-

Minor trimming: Use fine-grit abrasives to remove small amounts of material

-

Shimming: Add thin spacers to correct alignment issues

-

Reinforcement: Strengthen areas that require modification to maintain structural integrity

Adhesion Failures

Poor adhesion typically results from contaminated surfaces, incorrect adhesive selection, or improper environmental conditions during bonding. Prevention through proper surface preparation and environmental control eliminates most adhesion problems. If failures occur, complete removal and re-preparation of surfaces is usually necessary.

Clearance Issues

Insufficient clearance can cause contact between the tub and moving components, leading to wear and potential damage. Address clearance problems by modifying the tub rather than suspension components when possible, as this maintains the vehicle's original performance characteristics while accommodating the larger wheel wells.

Maintenance and Long-Term Care

Regular Inspection Procedures

Carbon fiber wheel tubs require minimal maintenance compared to metal alternatives, but regular inspection ensures continued performance and safety. Establish a inspection schedule that coincides with other vehicle maintenance activities, typically every 3,000-5,000 miles for racing applications.

Focus inspection efforts on:

-

Bond line integrity: Check for signs of delamination or adhesive failure

-

Fastener condition: Verify torque specifications and inspect for corrosion

-

Surface damage: Look for impact damage, cracks, or excessive wear

-

Clearance maintenance: Confirm adequate clearances remain after suspension wear

Repair Procedures

Minor damage to carbon fiber components can often be repaired using appropriate techniques and materials. Surface scratches and small impact damages respond well to proper repair procedures, while major structural damage typically requires component replacement.

Successful repairs require:

-

Damage assessment: Determine the extent and type of damage

-

Material compatibility: Use repair materials compatible with the original construction

-

Proper technique: Follow established carbon fiber repair procedures

-

Quality verification: Test repairs thoroughly before returning to service

Performance Benefits and Results

Weight Reduction Advantages

The weight reduction achieved through carbon fiber wheel tub installation provides immediate performance benefits across multiple vehicle systems. Unsprung weight reduction improves suspension response, reduces brake fade, and enhances acceleration characteristics. A typical installation saves 15-25 pounds of unsprung weight compared to steel alternatives.

Increased Tire Capacity

Carbon fiber wheel tubs enable the use of significantly larger tires, improving traction and cornering performance. Racing applications commonly accommodate tires up to 36 inches in diameter, providing substantial increases in contact patch area and load-carrying capacity. This capability translates directly into improved lap times and vehicle performance.

Structural Performance

Properly installed carbon fiber wheel tubs can actually strengthen the vehicle's rear structure by distributing loads more effectively than factory components. The material's high strength-to-weight ratio and ability to be engineered for specific load paths creates structures that outperform heavier alternatives while reducing overall vehicle weight.

Conclusion

Carbon fiber wheel tub installation represents a significant commitment to vehicle performance and capability. While the process requires careful attention to detail and proper technique, the results provide substantial benefits in weight reduction, tire capacity, and overall performance. Following this comprehensive four-step process ensures professional results that meet the demanding requirements of racing and high-performance applications.

Success depends on thorough planning, proper safety procedures, precise cutting and fitting, and professional-grade bonding techniques. Take time during each phase to verify quality and accuracy, as corrections become increasingly difficult as the installation progresses. With proper execution, carbon fiber wheel tubs provide years of reliable service while contributing to improved vehicle performance and capability.

Remember that this modification may affect vehicle safety systems and local regulations, so consult with qualified professionals and verify compliance with applicable rules before proceeding. The investment in quality materials and professional installation techniques pays dividends in performance, reliability, and safety throughout the component's service life.

For those seeking the ultimate in performance modification, carbon fiber wheel tubs represent the pinnacle of lightweight, high-strength construction. When installed properly using the techniques outlined in this guide, they provide the foundation for serious performance vehicles that demand the best in every component.