The Best Chassis Car to Buy in 2025: Your Complete Buyer's Guide to Performance Platforms

When it comes to building the ultimate performance machine or simply enjoying spirited driving, the foundation of everything lies beneath the surface—in the chassis. Whether you're a weekend track enthusiast, a modification aficionado, or someone who appreciates precision engineering, choosing the right chassis platform can make or break your automotive dreams. In 2025, the landscape of performance chassis options has never been more diverse, ranging from time-tested legends to cutting-edge modern marvels that push the boundaries of what's possible.

The chassis serves as the skeleton of any performance vehicle, dictating everything from handling characteristics and modification potential to long-term reliability and resale value. With manufacturers like BMW continuing to refine their legendary platforms, Toyota and Subaru collaborating on driver-focused designs, and companies like AME Motorsport providing extensive aftermarket support, today's enthusiasts have unprecedented choices for building their dream machine.

What Makes a Great Performance Chassis?

Understanding Chassis Fundamentals

The foundation of any great performance car starts with its chassis—the structural framework that connects every component and determines how your vehicle responds to inputs. A truly exceptional chassis must excel in several critical areas: torsional rigidity (resistance to twisting forces), weight distribution, and suspension geometry. The best performance chassis platforms, whether found in a BMW M3, Toyota 86, or Porsche 911, share common characteristics that separate them from ordinary vehicles.

Modern chassis engineering has evolved significantly from the simple ladder frames of decades past. Today's performance-focused platforms utilize advanced computer modeling and real-world testing to optimize every aspect of structural integrity. Companies like HcLaBo and WK Racing have revolutionized aftermarket chassis reinforcement, offering comprehensive upgrade packages that can transform even modest platforms into track-ready weapons. The key lies in understanding how load paths distribute forces throughout the structure, ensuring that energy from cornering, braking, and acceleration is managed efficiently without compromising vehicle dynamics or safety.

Weight distribution plays a crucial role in chassis performance, with the ideal 50/50 front-to-rear balance being the holy grail for many engineers. However, some of the world's best sports cars, including the iconic Porsche 911, prove that exceptional handling can be achieved even with unconventional weight distributions when paired with sophisticated chassis tuning and suspension geometry. The relationship between center of gravity, moment of inertia, and wheelbase creates the fundamental character of how any chassis responds to driver inputs.

Material Science: Carbon Fiber vs Aluminum vs Steel

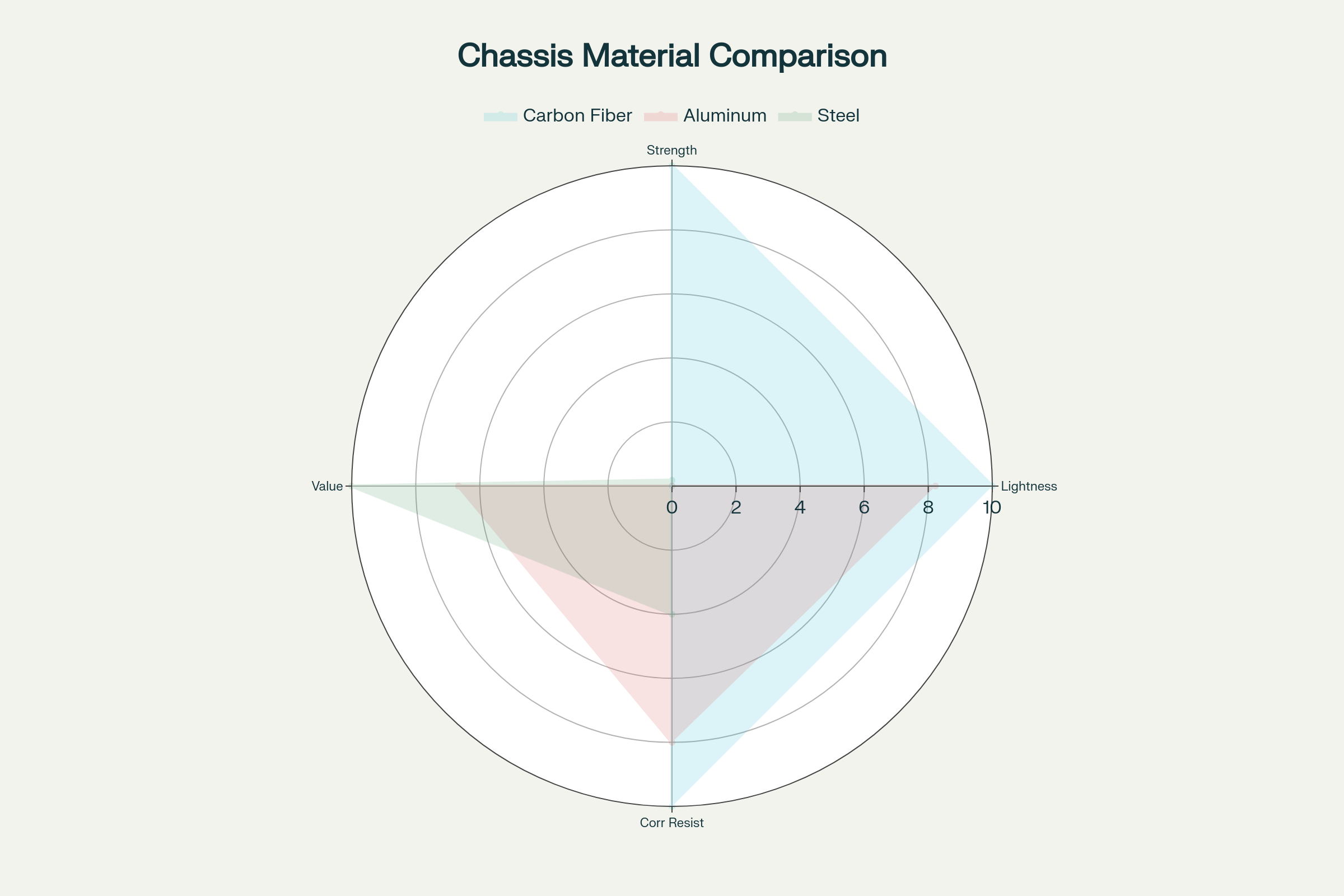

The choice of chassis materials represents one of the most significant decisions in modern automotive engineering, directly impacting weight, strength, cost, and manufacturing complexity. Carbon fiber stands as the pinnacle of chassis materials, offering an exceptional strength-to-weight ratio that surpasses traditional metals by substantial margins. With a density of just 1.6 g/cm³ compared to aluminum's 2.7 g/cm³, carbon fiber can deliver weight savings of up to 40% while maintaining superior structural integrity.

Steel remains the backbone of most production vehicles due to its excellent balance of cost, workability, and strength characteristics. High-strength steel alloys used in modern chassis construction can achieve tensile strengths exceeding 600 MPa while remaining relatively inexpensive to manufacture and repair. The material's excellent fatigue resistance makes it ideal for vehicles that will see extensive use, whether on the street or track. However, the weight penalty compared to exotic materials means that steel-chassis vehicles must compensate through superior engineering and design.

Aluminum offers a compelling middle ground, providing significant weight savings over steel while remaining more affordable than carbon fiber. Modern aluminum chassis, such as those found in high-end BMW and Audi models, utilize advanced alloys like 6061-T6 that deliver excellent strength characteristics while resisting corrosion. The material's excellent thermal conductivity also provides benefits in heat management, crucial for high-performance applications where chassis-mounted components generate significant thermal loads.

Chassis Geometry and Weight Distribution

The geometric relationships within a chassis determine fundamental handling characteristics that no amount of suspension tuning can fully overcome. Suspension pickup points, the locations where control arms and other components attach to the chassis, dictate how wheels move through their travel and how forces are transmitted back to the driver. The best performance chassis feature carefully optimized pickup point locations that minimize bump steer, reduce camber loss during cornering, and maintain consistent tire contact patches under all driving conditions.

Wheelbase and track width represent two of the most important dimensional aspects of chassis design. A longer wheelbase generally provides improved stability at high speeds and better ride quality, while a shorter wheelbase enhances agility and responsiveness in tight cornering situations. Track width affects the vehicle's resistance to body roll and its ability to generate lateral grip, with wider tracks generally providing superior cornering performance at the expense of increased tire wear and potentially reduced efficiency.

Torsional Rigidity Explained

Torsional rigidity measures a chassis's resistance to twisting forces, typically expressed in newton-meters per degree of twist. This characteristic directly impacts how effectively suspension components can control wheel movement and maintain tire contact with the road surface. A chassis with insufficient torsional rigidity will flex under cornering loads, creating inconsistent suspension geometry and unpredictable handling characteristics that make precise vehicle control difficult.

Modern performance chassis achieve exceptional torsional rigidity through strategic material placement and advanced structural design. Triangulation principles ensure that loads are distributed through multiple paths, preventing any single component from becoming overwhelmed. Companies specializing in chassis upgrades, such as those offering comprehensive reinforcement packages for popular platforms like the BMW E46 and Toyota 86, focus heavily on improving torsional rigidity through strategic bracing and structural reinforcement.

Types of Chassis Configurations

Monocoque vs Space Frame Construction

The fundamental approach to chassis construction divides into two primary philosophies: monocoque (unibody) and space frame designs, each offering distinct advantages for different applications. Monocoque construction integrates the chassis and body structure into a single unit, creating a lightweight and rigid platform that excels in both performance and manufacturing efficiency. This approach, used by the majority of modern sports cars including the BMW M3/M4, Toyota 86, and Honda Civic Type R, provides excellent torsional rigidity while maintaining relatively low production costs.

Space frame construction, exemplified by vehicles like the Chevrolet Corvette C8 and various Lotus models, utilizes a separate structural framework typically constructed from aluminum or steel tubing. This approach offers superior rigidity-to-weight ratios and provides easier access for modifications and repairs. The space frame design allows engineers to optimize load paths independently of body styling requirements, resulting in chassis that can achieve exceptional performance characteristics.

The choice between these construction methods often reflects the intended use and production volume of the vehicle. Monocoque designs excel for high-volume production and provide excellent crash protection through integrated crumple zones. Space frame construction offers advantages for low-volume production, racing applications, and situations where maximum structural efficiency takes priority over manufacturing costs.

Ladder Frame vs Unibody Design

While ladder frame construction represents one of the oldest chassis designs, it remains relevant for specific applications requiring maximum durability and load-carrying capacity. The ladder frame consists of two parallel rails connected by cross-members, creating a robust foundation that can handle extreme loads and abuse. However, this design philosophy prioritizes strength over weight efficiency, making it less suitable for performance-focused applications where agility and responsiveness are paramount.

Unibody design represents the evolution toward integrated construction, where the chassis and body structure work together to provide structural integrity. This approach, used by virtually all modern performance cars, offers significant advantages in weight reduction, manufacturing efficiency, and structural rigidity. The unibody design allows for more complex load paths and better integration of safety systems, making it the preferred choice for vehicles that must balance performance with practical considerations.

Modern unibody construction incorporates advanced materials and manufacturing techniques to achieve rigidity levels that surpass traditional ladder frame designs while maintaining significantly lower weight. Strategic use of high-strength steel in critical areas, combined with aluminum or even carbon fiber components in less critical locations, creates chassis that optimize material properties throughout the structure.

Tubular Chassis for Racing Applications

Tubular chassis construction represents the pinnacle of structural efficiency for racing applications, utilizing strategically placed steel or aluminum tubing to create incredibly rigid yet lightweight frameworks. This construction method, often called a space frame, allows engineers to place material exactly where needed to resist specific load cases while minimizing overall weight. The result is a chassis that can achieve exceptional performance characteristics impossible with conventional construction methods.

The primary advantage of tubular construction lies in its ability to create triangulated structures that distribute loads efficiently throughout the framework. Each tube serves a specific structural purpose, with the entire assembly working together to resist forces generated during aggressive driving. This approach allows for chassis that weigh significantly less than equivalent unibody designs while providing superior rigidity and durability under extreme conditions.

Companies like WK Racing and HcLaBo specialize in tubular chassis components and reinforcement systems that allow enthusiasts to upgrade production vehicles with race-inspired structural improvements. These systems can transform conventional unibody chassis into track-focused platforms capable of handling significantly higher loads and providing improved response characteristics.

Backbone Chassis Systems

The backbone chassis represents a unique approach to structural design, utilizing a single large central structure to connect front and rear suspension systems while providing space for driveline components. This design, made famous by vehicles like the Lotus Elan and various TVR models, offers several advantages including excellent torsional rigidity, simplified manufacturing, and efficient packaging of mechanical components.

Backbone construction allows for very high structural efficiency since the central spine can be designed specifically to resist the primary load cases experienced during dynamic driving. The design also provides natural protection for driveline components and creates a low center of gravity that enhances handling characteristics. However, the backbone approach can present challenges for interior packaging and may complicate body construction compared to conventional designs.

Top BMW Chassis Platforms for 2025

BMW E30/E36 - The Drift King's Choice

The BMW E30 and E36 chassis platforms have achieved legendary status among driving enthusiasts, representing the perfect balance of classical rear-wheel-drive dynamics and modern structural engineering. The E30, produced from 1982 to 1994, established BMW's reputation for creating chassis that prioritize driver engagement above all else. Its relatively simple construction, excellent weight distribution, and responsive steering characteristics make it an ideal platform for both street driving and motorsport applications.

E36 chassis development continued this philosophy while incorporating improved manufacturing techniques and enhanced structural rigidity. The platform's exceptional balance stems from its near-perfect weight distribution, sophisticated suspension geometry, and inherent structural strength that allows for significant power increases without compromising handling characteristics. Companies like WK Racing offer comprehensive upgrade packages for E30/E36 platforms, including reinforced subframes, adjustable suspension components, and chassis bracing systems that can transform these classics into modern track weapons.

The popularity of these platforms in drifting and track driving stems from their predictable handling characteristics and extensive aftermarket support. The chassis responds linearly to modifications, allowing drivers to fine-tune handling balance through suspension adjustments, weight reduction, and structural reinforcement. AME Motorsport offers a complete range of performance parts specifically designed for these platforms, from exhaust systems to complete engine management solutions.

BMW F80 M3/F82 M4 - Modern Performance

The F80 M3 and F82 M4 represent BMW's modern interpretation of high-performance chassis engineering, incorporating advanced materials and construction techniques while maintaining the brand's commitment to driver-focused dynamics. These platforms utilize extensive aluminum construction in critical areas, achieving significant weight reduction compared to their predecessors while providing improved structural rigidity and crash protection.

Carbon fiber reinforcement plays a crucial role in F80/F82 chassis design, with strategic placement of carbon fiber components reducing weight while enhancing structural integrity. The chassis incorporates advanced adaptive suspension systems that allow drivers to adjust damping characteristics in real-time, providing exceptional versatility for both street driving and track applications. The platform's sophisticated electronic stability systems work seamlessly with the chassis dynamics to provide both safety and performance.

Aftermarket support for F80/F82 platforms continues to expand, with companies like HcLaBo offering comprehensive chassis upgrade packages that include adjustable suspension components, reinforced mounting points, and aerodynamic enhancements. These platforms respond exceptionally well to modification, with many owners achieving significant performance improvements through careful chassis tuning and component upgrades.

BMW G20/G80 - Latest Generation Excellence

BMW's G20 and G80 platforms represent the cutting edge of chassis technology, incorporating lessons learned from decades of performance car development while embracing modern materials and manufacturing techniques. The G20 3-Series chassis provides an excellent foundation for performance modifications, with its advanced CLAR platform architecture offering exceptional structural rigidity and sophisticated suspension geometry.

G80 M3 chassis development focused on achieving the perfect balance between comfort and performance, utilizing adaptive systems that can transform the vehicle's character based on driving conditions. The platform incorporates extensive use of aluminum and high-strength steel, creating a structure that is both lighter and stronger than previous generations. Advanced manufacturing techniques allow for precise control of material properties throughout the chassis, optimizing performance while maintaining production efficiency.

The aftermarket industry has quickly embraced these newer platforms, with companies offering comprehensive upgrade packages that include suspension systems, chassis reinforcement, and performance components specifically designed to unlock the platform's full potential. The G20/G80 chassis responds exceptionally well to modification, with many enthusiasts achieving significant performance improvements through careful selection of aftermarket components and professional installation.

Best BMW Chassis Modification Potential

BMW chassis platforms offer exceptional modification potential due to their robust fundamental design and extensive aftermarket support. The key to successful BMW chassis modification lies in understanding the platform's inherent strengths and addressing any weak points through strategic upgrades. Subframe reinforcement represents one of the most important modifications for high-performance applications, as increased loads from upgraded engines and suspension components can overwhelm factory mounting points.

Suspension geometry optimization through adjustable control arms and bushings allows for precise tuning of handling characteristics while maintaining street usability. Companies specializing in BMW performance modifications offer comprehensive packages that include adjustable camber plates, reinforced mounting points, and upgraded bushings that work together to create a more responsive and precise chassis. The modular nature of BMW's engineering makes it relatively straightforward to upgrade individual components while maintaining overall system integration.

Japanese Chassis Champions

Toyota 86/Subaru BRZ - Balanced Brilliance

The Toyota 86 and Subaru BRZ platforms represent a masterclass in chassis engineering, prioritizing balance and driver engagement over raw power. Developed through a collaboration between Toyota and Subaru, these vehicles feature an exceptionally low center of gravity achieved through innovative packaging of the horizontally opposed boxer engine below the vehicle's beltline. This fundamental design characteristic creates handling dynamics that rival much more expensive sports cars.

Chassis rigidity in the 86/BRZ platforms exceeds that of many vehicles costing significantly more, thanks to strategic use of high-strength steel and advanced manufacturing techniques. The platform's suspension geometry has been optimized for maximum tire contact and predictable handling characteristics, making it an excellent choice for both novice and experienced drivers. The relatively light weight combined with excellent structural integrity creates a responsive platform that communicates road conditions clearly to the driver.

Aftermarket support for 86/BRZ platforms is exceptional, with companies like HcLaBo offering comprehensive chassis upgrade packages that include adjustable suspension components, reinforced mounting points, and aerodynamic enhancements. These platforms respond exceptionally well to modification, with many owners achieving significant performance improvements through suspension upgrades, weight reduction, and careful chassis tuning. The availability of comprehensive modification packages makes these vehicles ideal for enthusiasts who want to progressively improve their car's performance.

Nissan S-Chassis Heritage (S13/S14/S15)

The Nissan S-chassis lineage represents one of the most important developments in affordable performance car design, with the S13, S14, and S15 platforms achieving legendary status among driving enthusiasts worldwide. These chassis combine lightweight construction with excellent structural integrity, creating platforms that excel in both street driving and motorsport applications. The S-chassis design philosophy prioritizes simplicity and effectiveness, resulting in vehicles that are both engaging to drive and relatively straightforward to modify.

S13 chassis development focused on creating a lightweight, responsive platform that could deliver sports car performance at an affordable price point. The chassis utilizes a traditional unibody construction with strategic reinforcement in high-load areas, providing excellent structural integrity while maintaining reasonable production costs. The platform's multi-link rear suspension was revolutionary for its time, providing levels of adjustability and performance that were typically found only in much more expensive vehicles.

The S14 and S15 platforms refined the original S13 concept while incorporating improved materials and manufacturing techniques. These later generations feature enhanced structural rigidity, improved suspension geometry, and better integration of safety systems while maintaining the lightweight and responsive characteristics that made the original S13 so popular. The extensive aftermarket support for all S-chassis variants makes them ideal platforms for modification and customization.

Mazda MX-5 Miata - Lightweight Legend

The Mazda MX-5 Miata has consistently demonstrated that exceptional handling doesn't require excessive power or complex systems, instead relying on fundamental chassis excellence and intelligent engineering. Each generation of the MX-5 has prioritized weight reduction and structural efficiency, creating platforms that deliver pure driving enjoyment through careful attention to basic dynamic principles. The current ND generation achieves remarkable structural rigidity while maintaining the lightweight characteristics that define the MX-5 experience.

Chassis development for the MX-5 focuses on creating the most direct connection possible between driver and road, utilizing advanced materials and manufacturing techniques to achieve exceptional structural efficiency. The platform's low polar moment of inertia, achieved through careful mass distribution and compact packaging, creates handling characteristics that allow the vehicle to change direction with remarkable agility. This fundamental characteristic makes the MX-5 an excellent teaching tool for developing driving skills and understanding vehicle dynamics.

The MX-5's modification potential is exceptional due to its robust fundamental design and extensive aftermarket support. Companies offer comprehensive upgrade packages that include suspension systems, chassis reinforcement, and aerodynamic enhancements specifically designed to work together as integrated systems. The platform responds predictably to modifications, allowing owners to progressively improve performance while maintaining the vehicle's essential character and usability.

Honda Civic Type R - Front-Drive Excellence

The Honda Civic Type R represents the pinnacle of front-wheel-drive chassis engineering, demonstrating that exceptional performance isn't limited to rear-wheel-drive configurations. The platform incorporates advanced materials and sophisticated engineering solutions to overcome the fundamental limitations typically associated with front-wheel-drive layouts. Chassis rigidity approaches levels found in dedicated sports cars, while innovative suspension geometry minimizes the handling compromises traditionally associated with FWD platforms.

Honda's engineering team addressed front-wheel-drive limitations through careful attention to suspension geometry, differential design, and chassis tuning. The result is a platform that can generate exceptional cornering performance while maintaining the practical advantages of front-wheel-drive layout. Advanced torque vectoring systems work with the chassis dynamics to provide handling characteristics that rival many rear-wheel-drive sports cars.

The Type R's aftermarket support continues to grow as enthusiasts discover the platform's modification potential. Companies offer comprehensive upgrade packages that include suspension systems, chassis reinforcement, and engine performance modifications specifically designed to work together as integrated systems. The platform's robust fundamental design allows for significant performance improvements through careful modification and tuning.

European Engineering Excellence

Porsche 911 - The Benchmark

The Porsche 911 chassis has evolved continuously for over six decades while maintaining its fundamental rear-engine philosophy, proving that exceptional engineering can overcome apparent disadvantages through sophisticated execution. The 911's unique weight distribution, with the engine positioned behind the rear axle, creates handling characteristics that are unlike any other production vehicle. Modern 911 platforms demonstrate how advanced chassis engineering can transform potential liabilities into performance advantages.

992 generation 911 chassis incorporates extensive use of aluminum and high-strength steel, creating a structure that is both lighter and more rigid than previous generations. The platform's sophisticated adaptive suspension systems allow drivers to adjust chassis characteristics in real-time, providing exceptional versatility for different driving conditions. Advanced stability management systems work seamlessly with the chassis dynamics to provide both safety and performance while preserving the 911's unique character.

Aftermarket support for 911 platforms includes comprehensive upgrade options from companies specializing in Porsche performance. These modifications can significantly enhance the platform's already exceptional capabilities while maintaining the reliability and refinement that define the 911 experience. The 911's robust fundamental design allows for substantial performance improvements through careful selection and installation of aftermarket components.

Audi RS Platform Innovation

Audi's RS platforms represent some of the most technologically advanced chassis in production today, incorporating cutting-edge materials, manufacturing techniques, and electronic systems. The platforms utilize Audi's Quattro all-wheel-drive system integrated with sophisticated chassis dynamics to provide exceptional traction and stability under all conditions. Advanced torque vectoring capabilities allow these vehicles to achieve handling characteristics that approach those of rear-wheel-drive sports cars while maintaining the traction advantages of all-wheel drive.

Carbon fiber reinforcement plays a crucial role in RS platform design, with strategic placement of carbon components reducing weight while enhancing structural integrity. The chassis incorporates advanced adaptive systems that can adjust suspension, steering, and drivetrain characteristics based on driving conditions and driver preferences. This comprehensive approach to vehicle dynamics creates platforms that excel in multiple roles, from daily driving to track performance.

The modification potential of Audi RS platforms continues to expand as aftermarket companies develop components specifically designed for these advanced systems. While the platforms' sophisticated electronic integration can complicate modifications, companies specializing in Audi performance offer comprehensive solutions that maintain system integration while providing significant performance improvements.

Mercedes-AMG Chassis Technology

Mercedes-AMG chassis development focuses on combining exceptional performance with luxury and refinement, creating platforms that excel in multiple roles. The company's expertise in advanced materials and manufacturing techniques results in chassis that achieve remarkable structural efficiency while providing the comfort and refinement expected from a luxury vehicle. Active suspension systems allow real-time adjustment of chassis characteristics, providing versatility that few other manufacturers can match.

AMG's engineering philosophy emphasizes the integration of chassis, engine, and electronic systems to create cohesive performance packages that exceed the sum of their individual components. Advanced torque vectoring systems work with sophisticated chassis dynamics to provide exceptional handling while maintaining stability and safety margins. The result is platforms that can deliver supercar-level performance while remaining usable in everyday driving conditions.

Aftermarket support for AMG platforms includes options from companies specializing in Mercedes performance modifications. While the platforms' sophisticated systems can complicate modifications, specialized companies offer comprehensive solutions that enhance performance while maintaining the integration and reliability that define the AMG experience.

Lotus Philosophy - Adding Lightness

Lotus has consistently demonstrated that exceptional performance comes from minimizing weight rather than maximizing power, with their chassis designs representing some of the most efficient structures in automotive history. The company's "adding lightness" philosophy permeates every aspect of chassis development, from material selection to structural optimization. Modern Lotus platforms achieve remarkable structural efficiency through advanced materials and sophisticated engineering while maintaining the lightweight characteristics that define the brand.

Chassis development at Lotus focuses on creating the most direct connection possible between driver and road, utilizing advanced bonding techniques and exotic materials to achieve exceptional structural efficiency while minimizing weight. The company's expertise in composite materials and structural optimization creates platforms that deliver unmatched performance-to-weight ratios. This fundamental approach results in vehicles that can achieve supercar-level performance with relatively modest power levels.

American Muscle Chassis Options

Chevrolet Corvette C8 - Mid-Engine Revolution

The Chevrolet Corvette C8 represents a revolutionary departure from traditional American sports car design, adopting a mid-engine configuration that required completely rethinking chassis architecture and engineering. The platform utilizes advanced space frame construction with extensive use of aluminum and carbon fiber, creating a structure that achieves exceptional rigidity while maintaining reasonable weight. The mid-engine layout provides ideal weight distribution and handling characteristics that rival exotic European supercars.

C8 chassis engineering focused on creating a platform capable of handling significantly more power than the base model produces, ensuring that future variants can achieve even higher performance levels without compromising structural integrity. The sophisticated electronic systems integration allows for advanced traction management and stability control that work seamlessly with the chassis dynamics to provide exceptional performance and safety.

The C8's modification potential continues to develop as aftermarket companies create components specifically designed for the new platform. While the sophisticated systems integration requires specialized knowledge for modifications, early aftermarket offerings demonstrate significant potential for performance enhancement through careful component selection and professional installation.

Ford Mustang - Pony Car Evolution

The Ford Mustang chassis has evolved dramatically from its original 1960s design, with modern platforms incorporating advanced materials and sophisticated engineering while maintaining the affordable performance philosophy that defines the pony car segment. Current Mustang platforms utilize advanced unibody construction with strategic reinforcement in high-load areas, providing excellent structural integrity while maintaining the responsive handling characteristics that enthusiasts demand.

S550 platform development focused on creating a modern chassis that could deliver world-class performance while maintaining the Mustang's traditional character and affordable pricing. The platform incorporates advanced independent rear suspension and sophisticated electronic systems that work together to provide exceptional handling while maintaining the engaging driving experience that defines the Mustang. Advanced stability management systems provide safety and performance while preserving driver involvement.

Aftermarket support for Mustang platforms is extensive, with companies offering comprehensive modification packages that include suspension systems, chassis reinforcement, and engine performance upgrades. The platform's robust fundamental design and extensive aftermarket support make it an excellent choice for enthusiasts who want to progressively improve their vehicle's performance through modification and tuning.

Dodge Challenger/Charger - Old-School Muscle

The Dodge Challenger and Charger platforms represent a modern interpretation of classic American muscle car philosophy, prioritizing straight-line performance and comfort over ultimate handling precision. These platforms utilize robust chassis construction designed to handle extreme power levels while providing the comfortable ride quality expected from full-size American cars. The LX/LC platform architecture provides a solid foundation for high-performance applications while maintaining practical usability.

Chassis development for these platforms focused on creating structures capable of handling the extreme torque output of modern HEMI engines while providing acceptable handling characteristics for their size and weight. Advanced suspension systems and electronic stability control help manage the platforms' considerable mass while providing driver confidence and safety. The robust construction allows for significant engine modifications without compromising structural integrity.

Aftermarket support includes comprehensive upgrade options designed to enhance both performance and handling characteristics. While these platforms prioritize straight-line performance over ultimate handling precision, careful modification can significantly improve their dynamic capabilities while maintaining the comfortable ride quality that defines the American muscle car experience.

Cadillac V-Series Performance

Cadillac V-Series platforms demonstrate that American luxury manufacturers can create chassis that rival the world's best performance cars while maintaining the comfort and refinement expected from a luxury vehicle. The platforms incorporate advanced materials, sophisticated suspension systems, and cutting-edge electronic integration to create vehicles that excel in multiple roles. Magnetic Ride Control and other advanced systems allow real-time adjustment of chassis characteristics to provide exceptional versatility.

V-Series engineering focuses on creating platforms that can deliver supercar-level performance while maintaining the luxury appointments and ride quality that define the Cadillac brand. Advanced torque management systems and sophisticated chassis tuning create vehicles that can handle extreme power levels while remaining civilized in everyday driving conditions. The combination of American engineering philosophy with advanced technology creates unique performance characteristics.

Budget-Friendly Performance Chassis

Best Entry-Level Options Under $30,000

The performance chassis market offers exceptional value for budget-conscious enthusiasts, with several platforms providing world-class dynamics at accessible price points. The BMW E36 remains one of the best values in performance chassis, offering exceptional handling characteristics and extensive modification potential at prices starting under $20,000. These platforms provide an excellent foundation for learning vehicle dynamics and developing driving skills while offering significant room for performance improvement through modification.

Toyota 86/Subaru BRZ platforms represent excellent value propositions for buyers seeking modern performance chassis with warranty coverage and contemporary safety features. These vehicles provide exceptional handling dynamics and build quality while maintaining reasonable purchase and ownership costs. The extensive aftermarket support ensures that owners can progressively improve their vehicle's performance as their skills and budget allow.

Mazda MX-5 variants across multiple generations offer consistent value in the lightweight sports car segment, with even older generations providing exceptional driving dynamics and reliable performance. The platform's simple construction and extensive parts availability make it an excellent choice for budget-conscious enthusiasts who want to learn about vehicle modification and maintenance while enjoying exceptional driving dynamics.

Used Car Chassis Gems

The used car market contains numerous chassis gems that offer exceptional performance potential at attractive price points. Nissan 350Z platforms provide robust construction, powerful engines, and excellent modification potential at prices that make them accessible to younger enthusiasts. The platform's rear-wheel-drive layout and balanced design create handling characteristics that remain engaging even by modern standards.

BMW E46 platforms, particularly the non-M variants, offer exceptional value for buyers seeking proven chassis dynamics with reasonable purchase and maintenance costs. These vehicles provide an excellent introduction to BMW's engineering philosophy while offering significant potential for performance improvement through modification. The extensive aftermarket support and robust fundamental design make these platforms ideal for long-term ownership and development.

Honda S2000 platforms, while commanding premium pricing due to their cult following, represent some of the finest chassis engineering ever applied to an affordable sports car. The platform's sophisticated construction and exceptional materials quality create a driving experience that rivals much more expensive vehicles while providing the reliability and build quality that define Honda's engineering excellence.

Modification Potential vs Initial Cost

Evaluating the relationship between initial purchase cost and modification potential helps identify the platforms that offer the best long-term value for performance enthusiasts. BMW E30/E36 platforms excel in this regard, offering exceptional modification potential at relatively low purchase prices. The platforms' robust construction and extensive aftermarket support allow for significant performance improvements through suspension upgrades, engine modifications, and chassis reinforcement.

Toyota 86/Subaru BRZ platforms provide excellent modification potential despite higher initial costs, with the modern construction and sophisticated engineering providing a solid foundation for performance enhancement. The platform's excellent fundamental balance means that even modest modifications can provide significant improvement in performance and driver enjoyment.

The key to successful budget performance builds lies in selecting platforms with strong fundamental design and extensive aftermarket support, allowing for progressive improvement over time rather than requiring immediate major modifications to achieve satisfactory performance.

Hidden Chassis Heroes

Several platforms offer exceptional performance potential despite being overlooked by many enthusiasts. Infiniti G35/G37 chassis provide robust construction, powerful engines, and excellent modification potential at attractive price points. The platforms share many components with more expensive Nissan performance vehicles while offering luxury appointments and comfortable ride quality for daily use.

Acura RSX platforms, particularly the Type-S variants, demonstrate that front-wheel-drive chassis can provide exceptional performance when properly engineered. The platform's sophisticated construction and Honda's legendary build quality create vehicles that offer engaging driving dynamics while maintaining excellent reliability and reasonable ownership costs.

These hidden gems often provide the best value for enthusiasts willing to look beyond the most popular platforms, offering excellent performance potential and unique character at attractive price points.

Chassis Modification and Upgrades

Essential Chassis Reinforcement Components

Professional chassis modification begins with understanding the fundamental load paths and structural requirements of high-performance driving. Subframe reinforcement represents one of the most critical upgrades for vehicles intended for track use or significant power increases, as factory mounting points often cannot handle the increased loads generated by performance modifications. Companies like WK Racing and HcLaBo offer comprehensive reinforcement packages that strengthen critical mounting points while maintaining proper suspension geometry.

Strut tower braces provide one of the most cost-effective chassis improvements, connecting the suspension mounting points to reduce flex and improve handling precision. These components work by creating triangulated structures that distribute loads more effectively throughout the chassis, resulting in more consistent suspension geometry during dynamic driving. Modern strut braces utilize advanced materials like aluminum and carbon fiber to provide maximum effectiveness with minimal weight addition.

Roll cage installation represents the ultimate chassis reinforcement, providing both safety enhancement and dramatic improvements in structural rigidity. Professional cage installation requires careful consideration of mounting points, material selection, and integration with existing safety systems. While primarily designed for racing applications, well-designed roll cages can significantly improve the handling characteristics of street vehicles while providing additional occupant protection.

Suspension Geometry Optimization

Understanding and optimizing suspension geometry represents one of the most effective ways to improve chassis performance without major structural modifications. Adjustable control arms allow precise tuning of camber, caster, and toe settings to optimize tire contact patches for specific applications. Companies specializing in suspension geometry offer comprehensive packages that include adjustable upper and lower control arms designed to work together as integrated systems.

Camber plates and adjustable top mounts provide additional adjustment capability while often improving the precision of suspension movement. These components allow for fine-tuning of suspension geometry while providing more robust mounting solutions than factory components. The ability to adjust alignment settings enables optimization for different tire compounds, driving conditions, and performance priorities.

Bushing upgrades throughout the suspension system can dramatically improve chassis response and precision while maintaining reasonable ride quality for street use. Modern polyurethane and spherical bearing designs offer significant improvements over factory rubber bushings while providing various levels of performance enhancement and noise, vibration, and harshness characteristics.

Weight Reduction Strategies

Systematic weight reduction can provide performance improvements that rival expensive engine modifications while often improving multiple aspects of vehicle dynamics. Interior component removal offers the most accessible weight reduction opportunities, with rear seats, sound deadening, and unnecessary trim pieces representing significant weight savings potential. However, successful weight reduction requires careful consideration of structural integrity and legal requirements for street-driven vehicles.

Body panel substitution with lightweight materials like carbon fiber can provide substantial weight savings while often improving the vehicle's visual appeal. Hood, trunk lid, and door replacements can reduce weight significantly while maintaining structural functionality. However, the cost-effectiveness of these modifications varies significantly depending on the specific vehicle and intended use.

Wheel and tire selection represents one of the most effective weight reduction strategies, as unsprung weight reduction provides benefits that exceed the simple weight savings. Lightweight forged wheels can reduce unsprung weight by 10-20 pounds per corner while often providing improved strength characteristics compared to factory cast wheels.

Roll Cage and Safety Upgrades

Professional roll cage design requires careful consideration of structural requirements, material selection, and integration with vehicle systems. FIA and SCCA specifications provide guidelines for cage construction that ensure both safety and performance benefits while maintaining compliance with various racing organizations. Proper cage installation requires professional welding and careful attention to mounting point preparation and reinforcement.

Safety system integration becomes increasingly important as vehicles are modified for track use, with fire suppression systems, racing seats, and harnesses requiring careful installation to work effectively with roll cage structures. Modern safety equipment offers exceptional protection while often providing improved comfort and vehicle control compared to factory systems.

The combination of structural reinforcement and safety system upgrades creates vehicles that are not only faster and more capable but also significantly safer in extreme driving conditions. This comprehensive approach to vehicle modification ensures that performance improvements are achieved without compromising occupant safety or vehicle reliability.

Track vs Street Chassis Considerations

Daily Driving Comfort vs Performance

The eternal compromise between comfort and performance requires careful consideration of intended vehicle use and personal priorities. Modern adjustable suspension systems allow some degree of optimization for different conditions, but fundamental chassis characteristics still dictate the vehicle's basic personality. Adaptive damping systems found in vehicles like the BMW M3/M4 and various AMG models provide remarkable versatility, allowing transformation from comfortable daily drivers to focused track machines with the touch of a button.

Street-focused chassis setups prioritize ride comfort, noise reduction, and compliance with irregular road surfaces while maintaining acceptable handling characteristics for spirited driving. These setups typically utilize softer spring rates, more compliant bushings, and damping characteristics optimized for comfort rather than ultimate performance. The result is vehicles that remain enjoyable for daily driving while providing adequate performance for occasional track use.

Track-oriented chassis modifications often compromise daily driving comfort in pursuit of maximum performance capability. Stiffer spring rates, more aggressive damping, and reduced-compliance bushings create vehicles that communicate road conditions clearly to the driver while providing exceptional control in high-performance driving situations. However, these modifications can make the vehicle less comfortable for daily driving and may reduce long-term durability on rough road surfaces.

Track-Focused Chassis Setups

Dedicated track chassis configurations prioritize performance characteristics that may be impractical or uncomfortable for street use. Racing suspension systems utilize significantly stiffer spring rates and more aggressive damping to maintain precise wheel control under extreme lateral acceleration. These systems often sacrifice comfort entirely in favor of maximum performance capability and consistency during extended track sessions.

Aerodynamic modifications become increasingly important as vehicle speeds increase, with chassis modifications often required to accommodate additional downforce-generating components. Splitters, diffusers, and wings require structural mounting points that can handle significant aerodynamic loads while maintaining proper suspension geometry and vehicle balance.

Cooling system upgrades often necessitate chassis modifications to accommodate additional radiators, oil coolers, and brake cooling ducts. These modifications require careful planning to ensure proper airflow management while maintaining structural integrity and component accessibility for maintenance and adjustment.

Multi-Purpose Platform Selection

Selecting a chassis platform that can excel in multiple roles requires understanding the compromises involved and choosing vehicles with inherent characteristics that align with intended use patterns. BMW M3/M4 platforms exemplify successful multi-purpose design, providing exceptional track capability while maintaining reasonable comfort and practicality for daily driving. Advanced electronic systems allow these vehicles to transform their character based on driving conditions and driver preferences.

Porsche 911 variants demonstrate how sophisticated engineering can create vehicles that excel in multiple roles without major compromises. The platform's fundamental balance and advanced systems integration allow it to serve as both a comfortable grand tourer and a focused track weapon, depending on configuration and driver preferences.

The key to successful multi-purpose platform selection lies in choosing vehicles with robust fundamental design and sophisticated systems integration, allowing for optimization across different use cases without requiring major modifications or sacrificing reliability.

Climate and Condition Factors

Environmental considerations play a crucial role in chassis selection and modification, with different climates and road conditions favoring different approaches to vehicle setup. Cold weather performance requires chassis configurations that maintain effectiveness across wide temperature ranges while providing adequate traction on variable road surfaces. All-wheel-drive systems can provide significant advantages in challenging conditions while maintaining acceptable performance characteristics in ideal conditions.

Hot weather operation requires chassis modifications that prioritize cooling and thermal management, often necessitating additional ventilation and heat dissipation capability. Track operation in hot climates may require significant modifications to cooling systems and component selection to maintain consistent performance during extended high-load operation.

Road surface quality varies dramatically between regions, with some areas requiring chassis setups that can handle rough pavement while maintaining performance capability on smooth surfaces. The selection of spring rates, damping characteristics, and wheel/tire combinations should reflect the primary operating environment while providing acceptable versatility for different conditions.

Future-Proofing Your Chassis Choice

Electric Vehicle Chassis Evolution

The electrification revolution is fundamentally changing chassis design requirements, with battery packaging and cooling needs creating new challenges and opportunities for performance vehicle development. Tesla Model S Plaid and similar high-performance EVs demonstrate that electric powertrains can provide exceptional acceleration while requiring different approaches to chassis tuning and weight distribution. The low center of gravity provided by floor-mounted battery packs creates handling characteristics that differ significantly from traditional internal combustion engine vehicles.

Battery integration requires chassis designs that can accommodate large, heavy battery packs while maintaining structural integrity and crash protection. Modern EV chassis utilize advanced materials and construction techniques to offset the weight penalty of battery systems while providing the rigidity required for high-performance applications. The integration of battery cooling systems adds complexity to chassis design while creating new opportunities for thermal management.

Electric motor characteristics create different torque delivery patterns and weight distributions compared to traditional engines, requiring new approaches to suspension tuning and chassis dynamics. The instant torque delivery of electric motors places different demands on drivetrain and chassis components while providing opportunities for advanced torque vectoring and traction management systems.

Aftermarket Support and Parts Availability

Long-term parts availability represents a crucial consideration for chassis selection, as vehicles require ongoing support throughout their service life. BMW, Toyota, and Honda platforms generally provide exceptional long-term parts availability due to their popularity and the companies' commitment to supporting older vehicles. Specialized performance platforms may face parts availability challenges as they age, making early acquisition of critical components advisable for long-term ownership.

Aftermarket industry support varies significantly between platforms, with popular enthusiast vehicles receiving extensive aftermarket attention while more obscure platforms may have limited upgrade options. AME Motorsport, WK Racing, and HcLaBo represent companies that provide comprehensive support for popular performance platforms, ensuring that enthusiasts can continue improving and maintaining their vehicles for decades.

3D printing and modern manufacturing technologies are changing the aftermarket landscape, making it possible to reproduce discontinued components and create custom solutions for older platforms. These technologies ensure that well-designed chassis platforms can remain viable for enthusiast use long after manufacturer support ends.

Resale Value and Collectibility

Investment potential varies dramatically between different chassis platforms, with some vehicles appreciating significantly while others depreciate rapidly. Porsche 911 variants, particularly limited-production and high-performance models, have demonstrated exceptional value retention and appreciation potential. BMW M3/M4 models often maintain strong resale values due to their reputation for performance and build quality.

Market trends suggest that well-engineered chassis platforms with strong enthusiast followings tend to maintain value better than vehicles that prioritize luxury or technology over fundamental driving dynamics. Manual transmission vehicles and naturally aspirated engines often command premium pricing in the used market as these characteristics become increasingly rare in new vehicle production.

Rarity and significance play important roles in long-term collectibility, with limited-production vehicles and those with racing heritage often appreciating beyond their initial purchase prices. The key lies in selecting vehicles with strong fundamental engineering and cultural significance that transcends simple transportation needs.

Technology Integration Potential

Modern electronics integration capabilities vary significantly between platforms, with some vehicles offering extensive customization and upgrade potential while others limit modification possibilities through complex electronic systems. BMW and Audi platforms generally provide good integration potential for aftermarket electronics while maintaining factory system functionality.

Autonomous driving technology development may impact the collectibility and desirability of manually driven vehicles, potentially increasing the value of chassis platforms that prioritize driver engagement over electronic assistance. Vehicles with minimal electronic intervention may become increasingly desirable as driving automation becomes more prevalent.

Connectivity and infotainment systems continue evolving rapidly, making platforms with upgradeable systems more attractive for long-term ownership. The ability to update and improve electronic systems while maintaining mechanical excellence ensures that great chassis platforms remain relevant despite changing technology landscapes.

Conclusion

The world of performance chassis offers unprecedented choice and opportunity for driving enthusiasts in 2025, with options ranging from time-tested classics to cutting-edge modern platforms that push the boundaries of automotive engineering. Whether your priorities lie with BMW's legendary rear-wheel-drive dynamics, Toyota's perfectly balanced 86/BRZ platform, Porsche's uncompromising engineering excellence, or the revolutionary mid-engine Corvette C8, the key lies in understanding your specific needs and selecting a platform that aligns with your intended use, budget, and long-term goals.

The most successful chassis choices balance fundamental engineering excellence with practical considerations like aftermarket support, parts availability, and modification potential. Companies like AME Motorsport, WK Racing, and HcLaBo continue expanding the possibilities for chassis enhancement, ensuring that enthusiasts can progressively improve their vehicles' performance while maintaining reliability and street usability.

Looking toward the future, the chassis landscape will continue evolving as electrification technologies mature and new materials and manufacturing techniques become available. However, the fundamental principles of exceptional chassis design—structural rigidity, optimal weight distribution, sophisticated suspension geometry, and driver-focused engineering—will remain constant. The platforms that prioritize these characteristics while providing robust foundations for modification and improvement will continue delivering exceptional driving experiences regardless of technological changes.

For enthusiasts entering the performance chassis world, starting with proven platforms like the BMW E36, Toyota 86/BRZ, or Mazda MX-5 provides excellent learning opportunities while offering significant modification potential at reasonable cost. More experienced drivers seeking ultimate performance may find exceptional value in platforms like the BMW F80 M3, Porsche 911 variants, or the revolutionary Chevrolet Corvette C8.

Remember that the best chassis is ultimately the one that brings you the most driving satisfaction while fitting within your practical constraints. Whether that means weekend track days, spirited canyon drives, or simply enjoying the daily commute, the right chassis selection will transform every journey into an opportunity for automotive enthusiasm and driving excellence.